Beating machine capable of repeatedly changing flow directions of paper pulp

A technology of flow direction and beating machine, applied in the field of industrial pulping and papermaking, can solve the problem of not taking beating effect into consideration, and achieve the effects of improving mechanical processing efficiency, improving beating efficiency, and large effective area range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention. It should be noted that these drawings are all simplified schematic diagrams, and only schematically illustrate the basic structure of the present invention, so they only show the configurations related to the present invention.

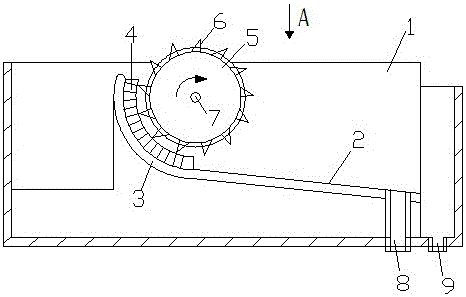

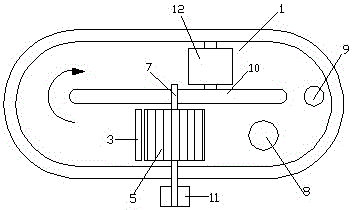

[0026] figure 1 It is a schematic diagram of the structure of the present invention. The arrow in the figure indicates the pulp flow direction. It can be seen from the accompanying drawings that the beater which can repeatedly change the pulp flow direction includes a pulp tank 1, and a flying knife roller 5 is arranged in the pulp tank 1. The bottom of the slurry pool 1 is provided with a sewage outlet 9 and a discharge port 8, the center of the flying k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com