Middle filter screen type tentering setting machine

A tenter setting machine and filter screen technology, which is used in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc. Ensure the quality of the fabric and avoid the effect of fabric wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

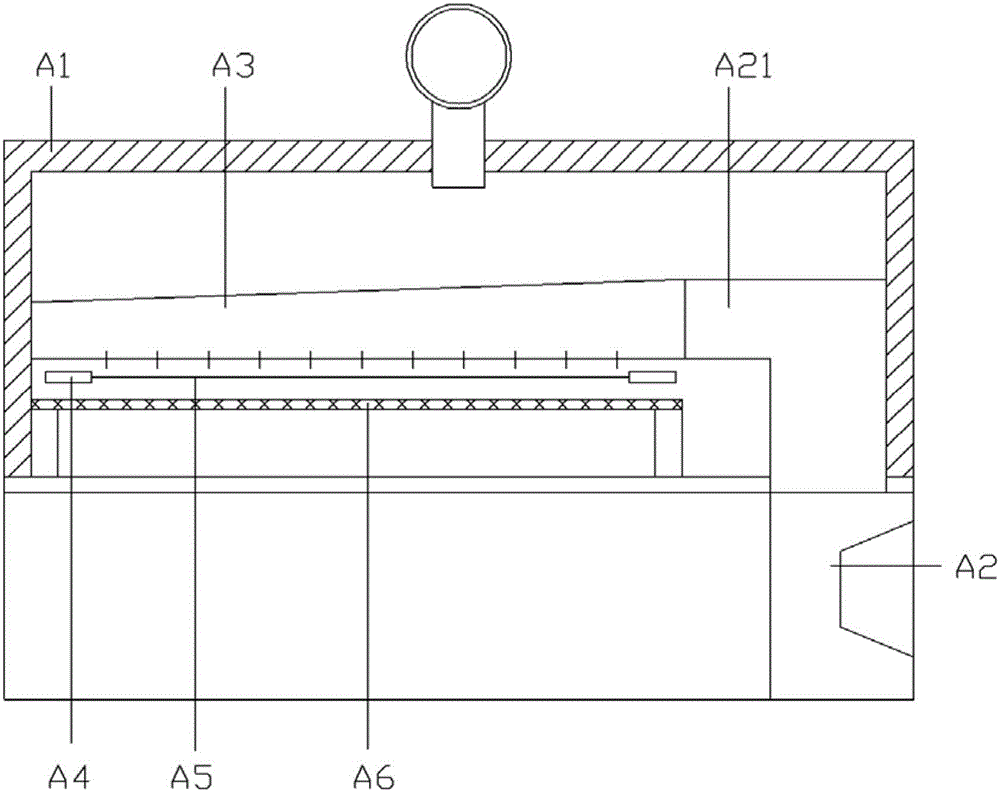

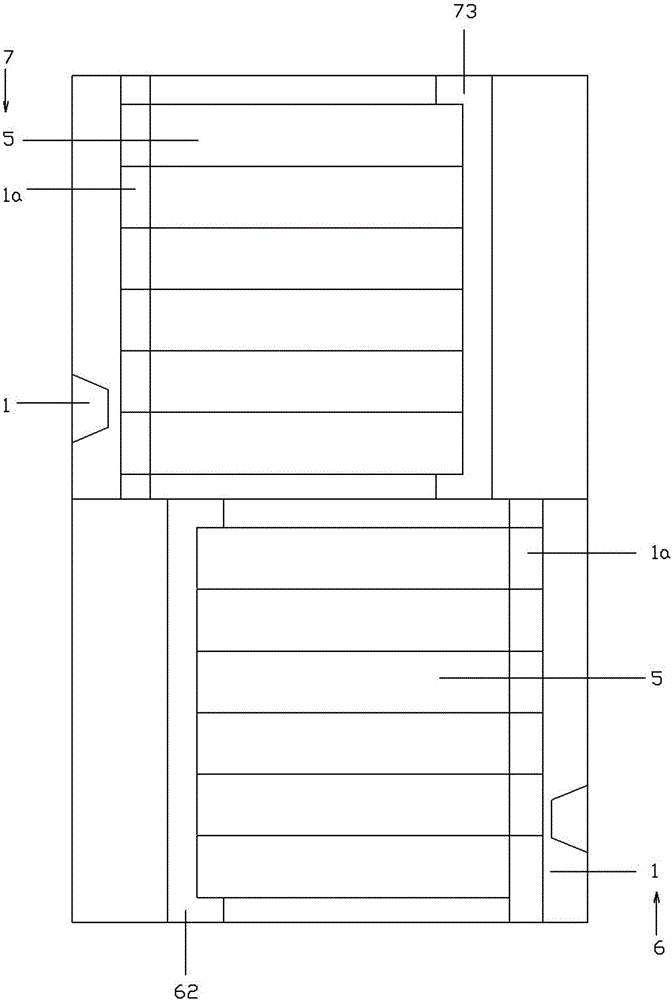

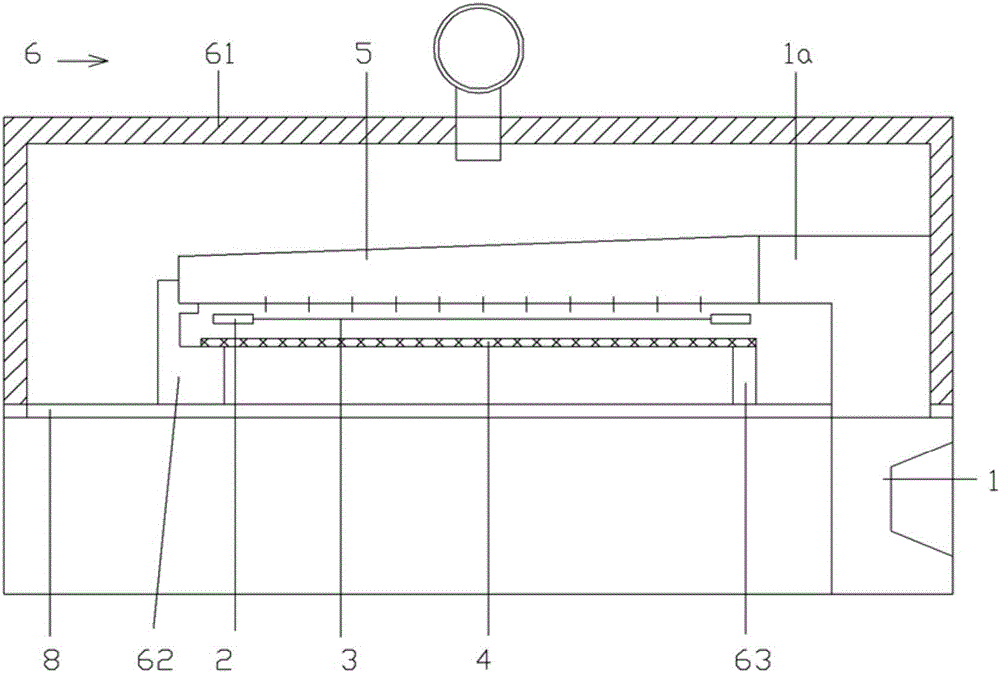

[0015] Example: see Figures 2 to 4 As shown, the intermediate filter type stenter setting machine includes a static pressure box 1, a cloth feeding chain 2, a cloth 3, a filter 4 and an air nozzle 5, and the two sides of the cloth 3 are clamped on the cloth feeding chain 2, and the cloth 3 is located at Below the tuyere 5, the filter screen 4 is located below the fabric 3, the two adjacent oven units of the tenter setting machine are the first oven unit 6 and the second oven unit 7, the structure of the first oven unit 6 is, The bottom of an oven unit casing 61 is a plenum box 1, and the plenum box 1 is positioned at the right side of the first oven unit casing 61. The plenum box 1 has an air outlet pipe 1a, and the air outlet pipe 1a communicates with the tuyere 5. The upper end of static pressure box 1 is fixed with support plate 8, and the first oven unit casing 61 is fixed on the support plate 8, and the first oven left support 62 and the first oven right support 63 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com