Method for lactic acid fermentation thallus residue pretreatment and method for circulation fermentation production of lactic acid

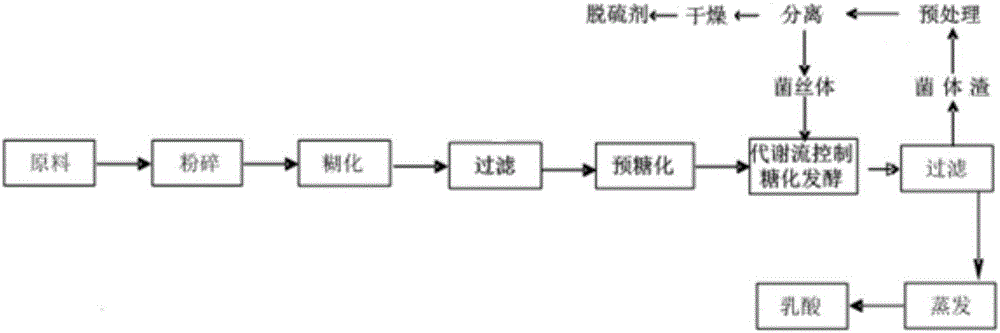

A technology of lactic acid fermentation and cyclic fermentation, applied in fermentation and other directions, can solve the problems of nutrient waste, waste residue pollution, etc., and achieve the effect of reducing dosage, realizing resource recycling, and reducing consumption of raw and auxiliary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for cyclic fermentation production of lactic acid described in this embodiment comprises the following steps:

[0030] (1) Raw material preparation: take corn and go through impurity removal, pulverization, pulping, jet liquefaction and filtration; obtain a liquefied sugar solution with a DE value of 22%, and the total sugar content in the liquefied sugar solution is 120g / L;

[0031] (2) Pre-saccharification: The pre-saccharification temperature is 59°C, and the liquefied sugar solution is added into a sterilized and sterilized fermenter for pre-saccharification; 3% hydrochloric acid is added to adjust the pH of the liquefied sugar solution to 4.5±0.1, and the saccharification Add 400U of glucoamylase according to the amount of enzyme added per gram of total sugar in the liquefied sugar liquid, and feed sterile air into the fermenter to keep the pressure in the tank at 0.2Mpa, and the pre-saccharification time is 4 hours to obtain a fermented feed liquid; The...

Embodiment 2

[0039] The method for cyclic fermentation production of lactic acid described in this embodiment comprises the following steps:

[0040] (1) Raw material preparation: the corn is removed from impurities, pulverized, pulped, sprayed and liquefied and filtered; a liquefied sugar solution with a DE value of 28% is obtained, and the total sugar content in the liquefied sugar solution is 180 g / L;

[0041] (2) Pre-saccharification: control the pre-saccharification temperature to 70°C, add the liquefied sugar solution into a sterilized and sterilized fermenter for pre-saccharification; add sulfuric acid with a mass fraction of 2% to adjust the pH of the liquefied sugar solution to 4.4, and glucoamylase According to the amount of glucoamylase added per gram of total sugar in the liquefied sugar liquid, 400 U of glucoamylase was added, and sterile air was introduced into the fermenter to keep the pressure in the tank at 0.1Mpa, and the pre-saccharification time was 6 hours to obtain a f...

Embodiment 3

[0049] The method for cyclic fermentation production of lactic acid described in this embodiment comprises the following steps:

[0050] (1) Raw material preparation: the corn is removed from impurities, pulverized, pulped, sprayed and liquefied and filtered; a liquefied sugar solution with a DE value of 25% is obtained, and the total sugar content in the liquefied sugar solution is 140 g / L;

[0051] (2) Pre-saccharification: The pre-saccharification temperature is 50°C, and the liquefied sugar solution is added into a sterilized and sterilized fermenter for pre-saccharification; hydrochloric acid with a mass fraction of 1% is added to adjust the pH of the liquefied sugar solution to 4.6, and the glucoamylase Add 600 U of glucoamylase per gram of total sugar in the liquefied sugar liquid, and feed sterile air into the fermenter to keep the pressure inside the tank at 0.4Mpa. The pre-saccharification time is 3.5 hours to obtain the fermentation feed liquid. DX value is 90%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com