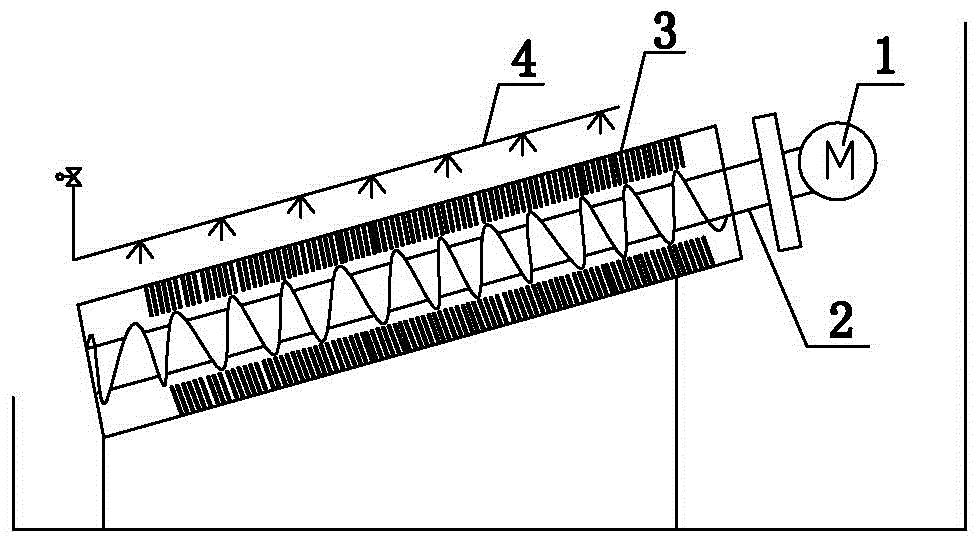

Variable-gap screw extrusion/dewatering integrated machine

An all-in-one machine and screw press technology, which is applied in dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of small gaps and inconvenient cleaning of wedge-shaped filter screens, and achieve good results. The effect of the dehydrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

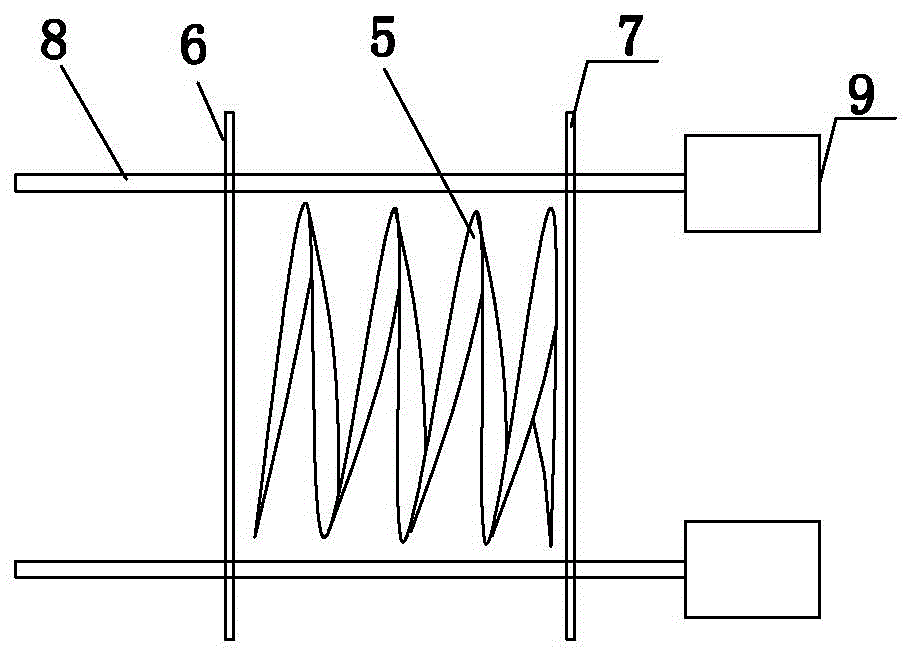

[0015] Such as figure 2 shown.

[0016] A variable-gap screw press dehydration integrated machine, which includes a drive motor 1, a variable-pitch shaft 2 and a cleaning system 4, the variable-pitch shaft 2 is covered with a stainless steel elastic filter 5, such as figure 2 As shown, the discharge end of the stainless steel elastic filter screen 5 is equipped with a fixed platen 6, and the feed end is equipped with a movable platen 7. Both the fixed platen 6 and the movable platen 7 are installed on the guide shaft 8, and the movable platen 7 is connected to drive it along the The drive mechanism 9 for the guide shaft 8 to move. During specific implementation, the quantity of driving mechanism 9 is preferably identical with the quantity of guide shaft 8, to realize synchronous pressing and unclamping, also can adopt a driving mechanism multi-point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com