Lightweight multifunctional container portal crane and assembly method thereof

A gantry crane and container technology, which is applied to cranes, trolley cranes, transportation and packaging, etc., can solve problems such as difficulties, affordability, and backward research and development capabilities of rail cranes, and achieve lightweight and convenient alignment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing.

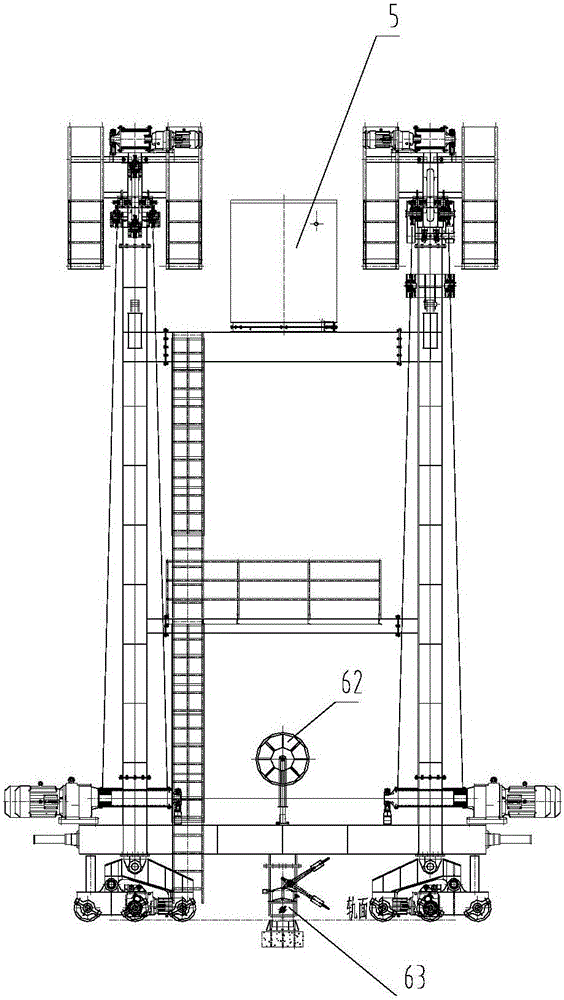

[0048] Such as figure 1 , 2 As shown, the present embodiment provides a lightweight multifunctional container gantry crane, which includes a gantry assembly 1, a walking trolley 4 installed on the four corners of the gantry assembly 1, Complete hoisting mechanism 2, spreader 3, driver's cab 5, stairway railing 6, electrical system 7, cable reel 62, windproof anchor 63.

[0049] Such as Figure 3-6As shown, the door frame assembly includes two door frames arranged in parallel, the door frame is composed of a main beam 8 and legs 9 at both ends of the main beam 8, and the two door frames pass through the upper beam 10 and the small beam 11 , The lower crossbeam 12 is connected, the main structural form of the main beam 8 adopts a box-shaped beam section, is provided with partitions and longitudinal reinforcement ribs, and ear beams are set on both sides of the lower part a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com