Automatic magnet assembly tray supply mechanism

A magnet group, automatic technology, applied in the direction of destacking, transportation and packaging of objects, can solve the problems such as the inability of the magnet to fall accurately, the repeated positioning accuracy is not high, and the production cost is increased, so as to save labor costs and save money. The effect of short labor and maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

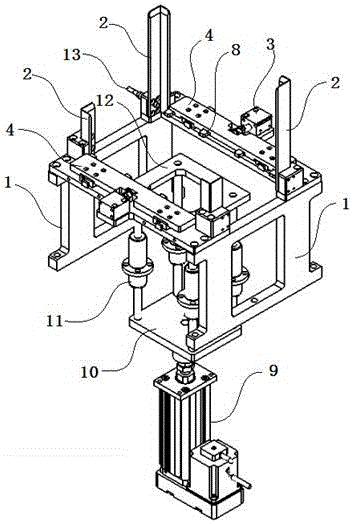

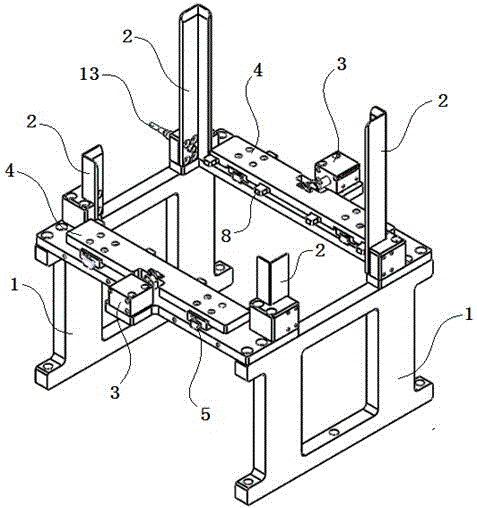

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

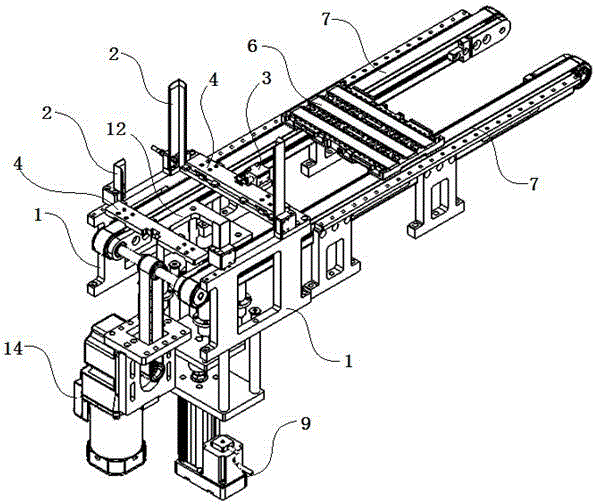

[0022] see Figure 1-4 As shown, a tray mechanism for automatic magnet assembly is composed of a storage mechanism, a locking mechanism, a holding mechanism and a transmission mechanism.

[0023] The storage mechanism includes a bracket 1 and four ribs 2, and the four ribs 2 are respectively vertically arranged on the four corners of the upper end surface of the bracket 1;

[0024] The left and right ends of the upper end surface of the support 1 are respectively provided with a set of locking mechanisms, and each set of locking mechanisms includes a flat push cylinder 3, a locking plate 4 and a pair of slide rails 5, the locking The plate 4 is arranged on the upper end surface of the bracket 1 through the slide rail 5, the flat pushing cylinder 3 is arranged on the outside of the clamping plate 4, and the push rod of the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com