Intravenous needle tab feeding mechanism

A technology of venous needles and fins, which is applied in the direction of conveyor objects, transportation and packaging, slideways, etc., and can solve the problems of inconsistent positions of plastic needle exhaust ports and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

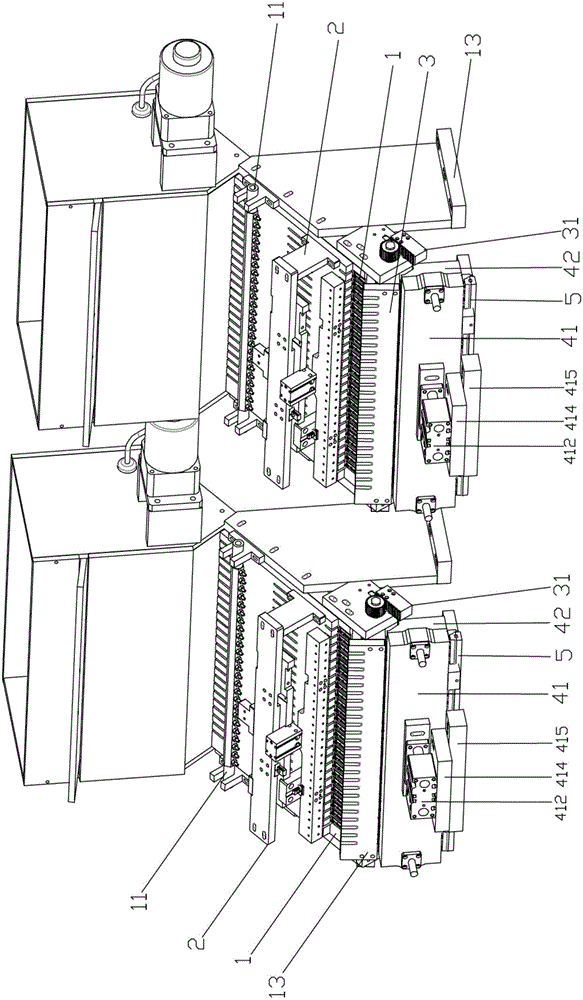

[0055]Such as Figure 2~18 As shown, the present invention provides a specific embodiment of a venous needle flap feeding mechanism, including a needle handle main board 1 for conveying the venous needle flap 6, a pusher assembly 2 for pushing the venous needle flap 6, and a The feeding seat 3 that rotates and guides the delivery of the venous needle wing 6, the guide device for conveying the venous needle wing 6 downward, and the venous needle jig 5 that is used to receive the venous needle delivery in the guide device; the pusher assembly 2. It is possible to push the vein needle fin 6 conveyed along the needle handle main board 1 to the bottom end of the needle handle main board 1 into the feeding seat 3, and then pass the vein needle fin 6 in the feeding seat 3 through the guide device Delivered downwards in the venous needle fixture 5.

[0056] Such as figure 2 , image 3 with Image 6 As shown, the needle handle main board 1 is provided with a plurality of grooves I...

Embodiment 2

[0073] On the basis of above-mentioned embodiment 1, as figure 1 As shown, two venous needle fin feeding mechanisms in the present invention are arranged side by side, wherein several venous needle jigs 5 can be discharged along multiple falling tracks of the bottom guide devices of the two venous needle fin feeding mechanisms. The arrangement direction moves circularly or reciprocally; since the length of the overlapping part between two adjacent slotted holes 502 in the groove V501 provided on the venous needle jig 5 is half the length of the slotted hole 502 or half The width of a venous needle wing 6, so a venous needle fixture 5 (that is, a unit length) embedded slot 502 can accommodate two rows of venous needle wings 6 conveyed by the venous needle wing feeding mechanism, thereby realizing A venous needle jig 5 can sequentially receive a row of the two venous needle fin feeding mechanisms respectively transported by moving in the arrangement direction of a plurality of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com