Three-dimensional printer integrated double extruder heads with double cooling air openings

A technology of 3D printers and extruder heads, applied in the direction of additive processing, etc., can solve the problems of complicated maintenance, heavy operation, and many accessories, and achieve the effect of simplified accessories, multiple functions, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

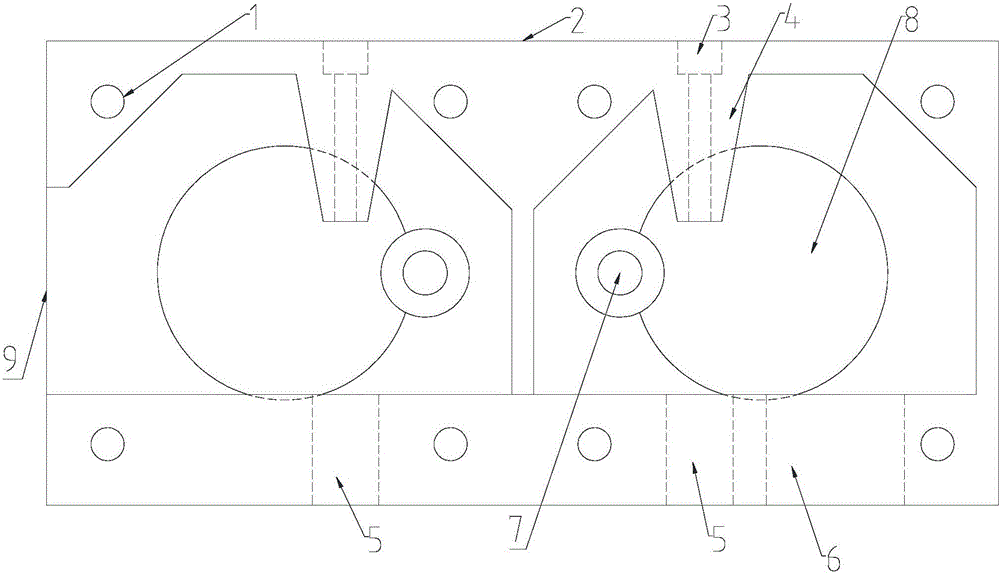

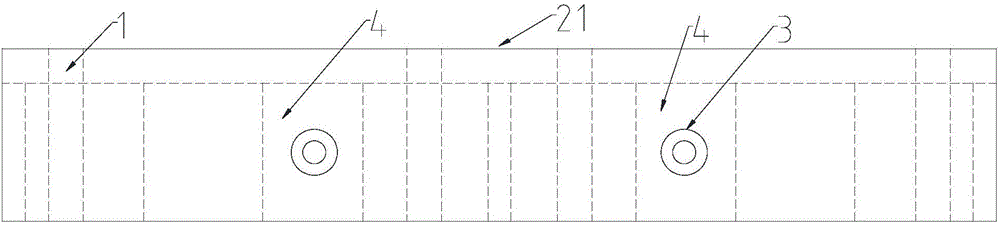

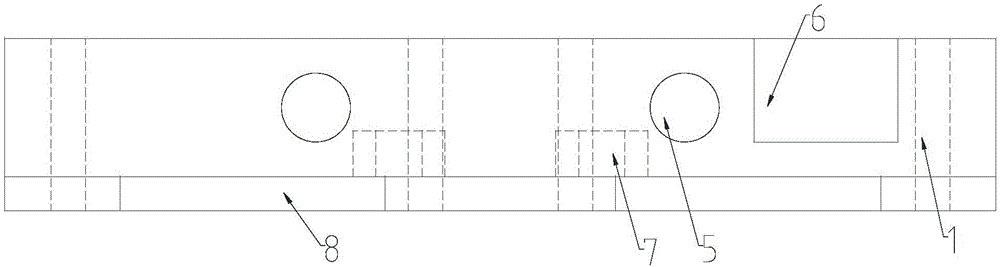

[0017] see Figure 1 ~ Figure 3 , a 3D printer integrated double extruder head with dual cooling air outlets of the present invention is characterized in that it includes a housing 2, and the front side of the housing 2 is provided with two left and right concave grooves , and one of the grooves is opened on the side wall of the housing 2 to form an air outlet 9, and the housing back 21 corresponding to each groove is respectively provided with an extrusion motor shaft hole 8, and the upper wall of the groove is integrated There is a wire feeding tube 4 protruding downwards, the top of the wire feeding hole of the wire feeding tube 4 is located on the top surface of the housing 2, and the outlet of the wire feeding hole of the wire feeding tube 4 is located in the wire feeding tube The bottom end of 4 is provided with a throat connection hole 5 on the lower wall of the groove corresponding to the bottom of the wire feeding pipe 4; the housing back 21 located in the groove is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com