Automatic production equipment for power wires

A technology for production equipment and power cords, applied in the field of automated power cord production equipment, can solve the problems of low production efficiency, low product quality stability, and high labor costs, and achieve the effects of improving production efficiency, strong practicability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

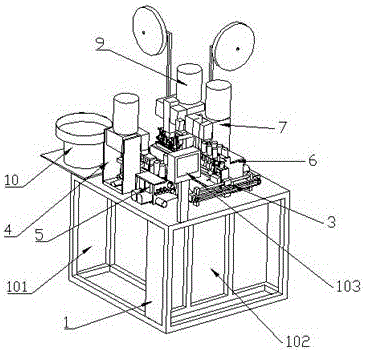

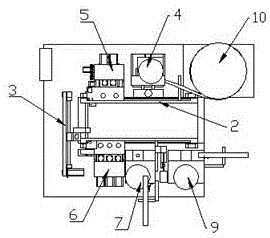

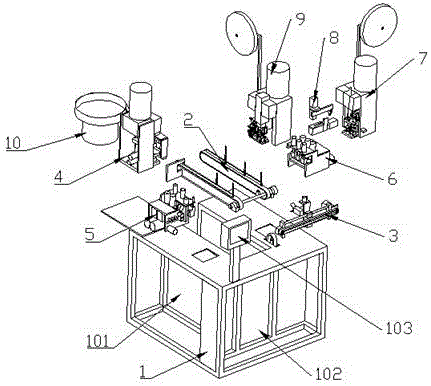

[0024] An automatic production equipment for power cords, comprising a main body structure 1, a chain transmission mechanism 2 fixed on the main body structure 1 and operating independently at the same time, a gripper wire feeding mechanism 3, an integrated inner frame end shaping mechanism 4 at the tail, and a head part line Peeling mechanism 5, tail section line stripping mechanism 6, ground wire end-breaking mechanism 7, ground wire separation mechanism 8, zero live wire end-breaking shaping mechanism 9 and vibration feeding tray 10.

[0025] The whole of the main structure 1 is U-shaped, and the left and right ends of the main structure are processing waste centralized collection areas 101, which are used to centrally collect the material waste left by the power cord during the processing process due to peeling and beating; the main structure The closed end is the installation area 102, which is used to install the electrical control system; the upper surface of the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com