Automatic expanding connection device at engine oil filling port

A technology for oil filling and expansion, which is applied in the field of automatic expansion and connection devices for oil filling, can solve the problems of time-consuming and laborious expansion processing, unevenness, etc., so as to improve the safety factor, reduce energy consumption, and meet the prerequisite requirements of the brazing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

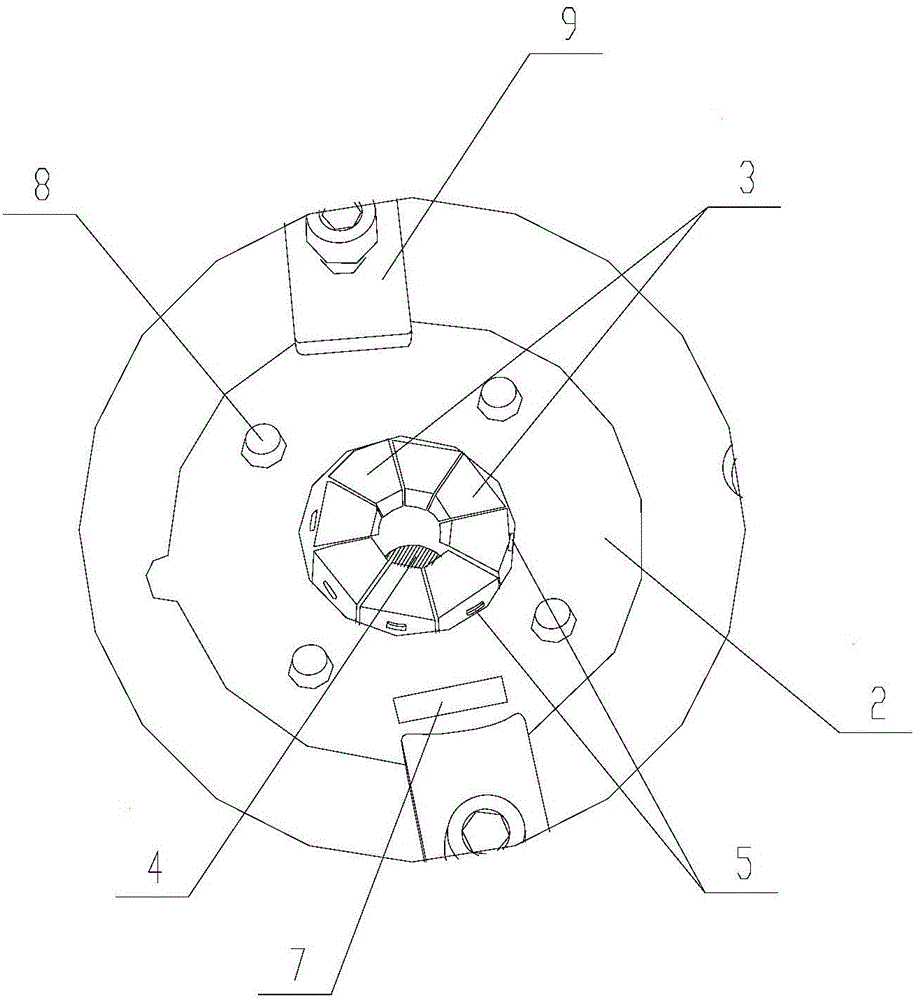

[0020] Such as figure 1 with 2 As shown in the figure, an automatic expansion device for the oil filling port includes a chassis 1. An expansion mold is provided on the chassis 1. A pneumatic power system is arranged inside the chassis 1. The expansion mold is connected to the pneumatic power system through a lifting cylinder, and the expansion mold It is composed of two parts: the fixed part of the flange plate 2 and the expansion joint of the oil filling port. The expansion joint of the oil filling port is arranged in the center of the fixed part of the flange plate 2. The expansion shaft 4 is composed of expansion joints 3 with expansion protrusions 5 on the outside of each expansion joint 3. A plurality of expansion joints 3 form a circle, and the expansion joint shaft 4 is located in the center of the circle surrounded by the expansion joints 3. The expansion joints The shaft 4 is connected with the lifting cylinder, the chassis 1 is equipped with a foot switch 6, the pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com