Composite elastic waist lining and manufacturing process thereof

A production process and waist lining technology, applied in clothing, protective clothing, special outerwear, etc., can solve the problems of no elastic waist lining buffer zone, discomfort, and no massage lumbar spine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

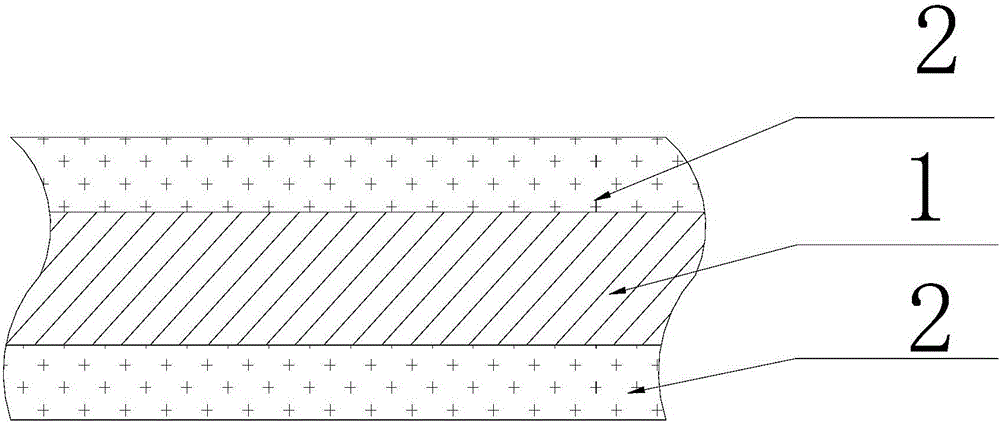

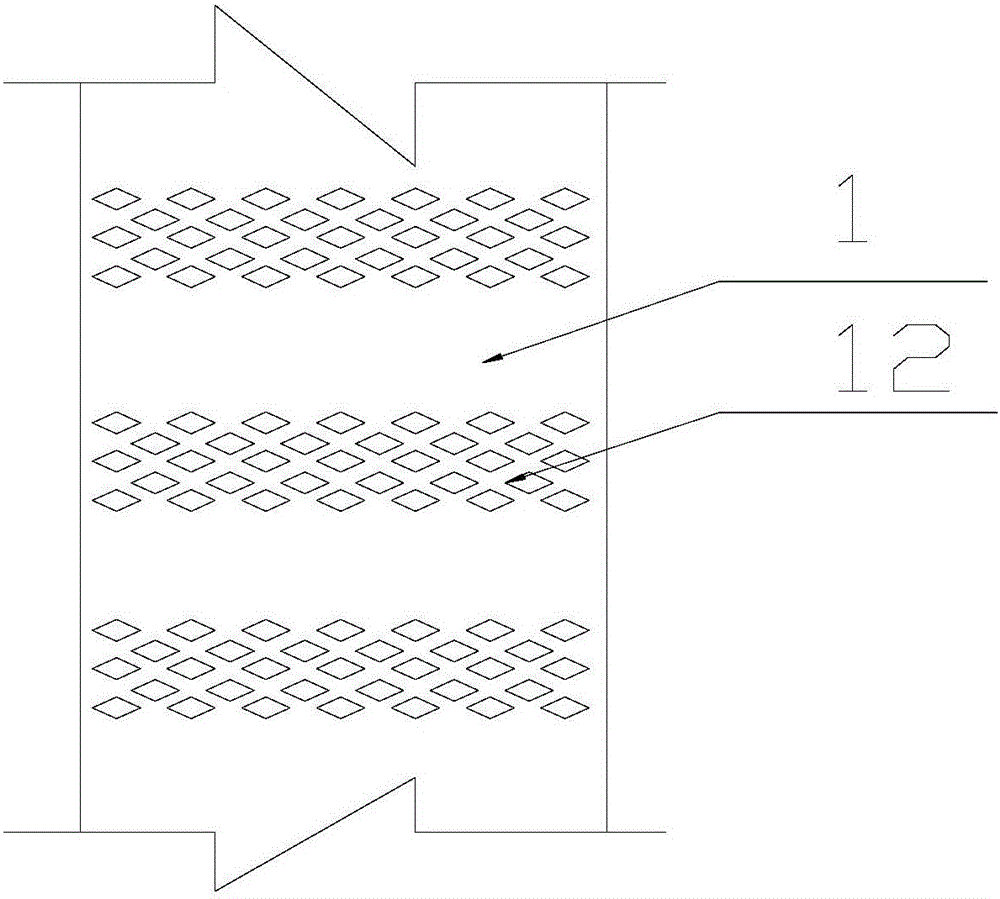

[0022] refer to Figure 1-2 , a composite elastic waist lining of the present invention, comprising a composite elastic waist lining base fabric layer 1 and a coating 2, the upper and lower sides of the composite elastic waist lining base fabric layer 1 are coated with a coating 2, and the composite elastic waist lining The base fabric layer 1 is provided with an elastic waist lining buffer area 12, and the composite elastic waist lining base fabric layer 1 is formed by mixing and hot-rolling magnetic fibers, polyurethane fibers and ES adhesive fibers. The ratio of parts by weight of each component of the composite elastic waist lining base cloth layer 1 is: 50-60 parts of magnetic fiber, 62-70 parts of polyurethane fiber, 5-8 parts of ES adhesive fiber, the elastic waist A number of holes are neatly arranged on the lining area 12, and the distance between two adjacent holes is equal. The shape of the holes on the elastic waist lining area 12 is rhombus, and the composite elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com