A conveying trough for a combine harvester with the function of forward-rotating conveying and reverse-reversing grass removal

A technology of combine harvesters and conveying troughs, which is applied in the directions of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of increased probability of failure and complex structure, so as to improve efficiency and safety, and simplify the transmission system. , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

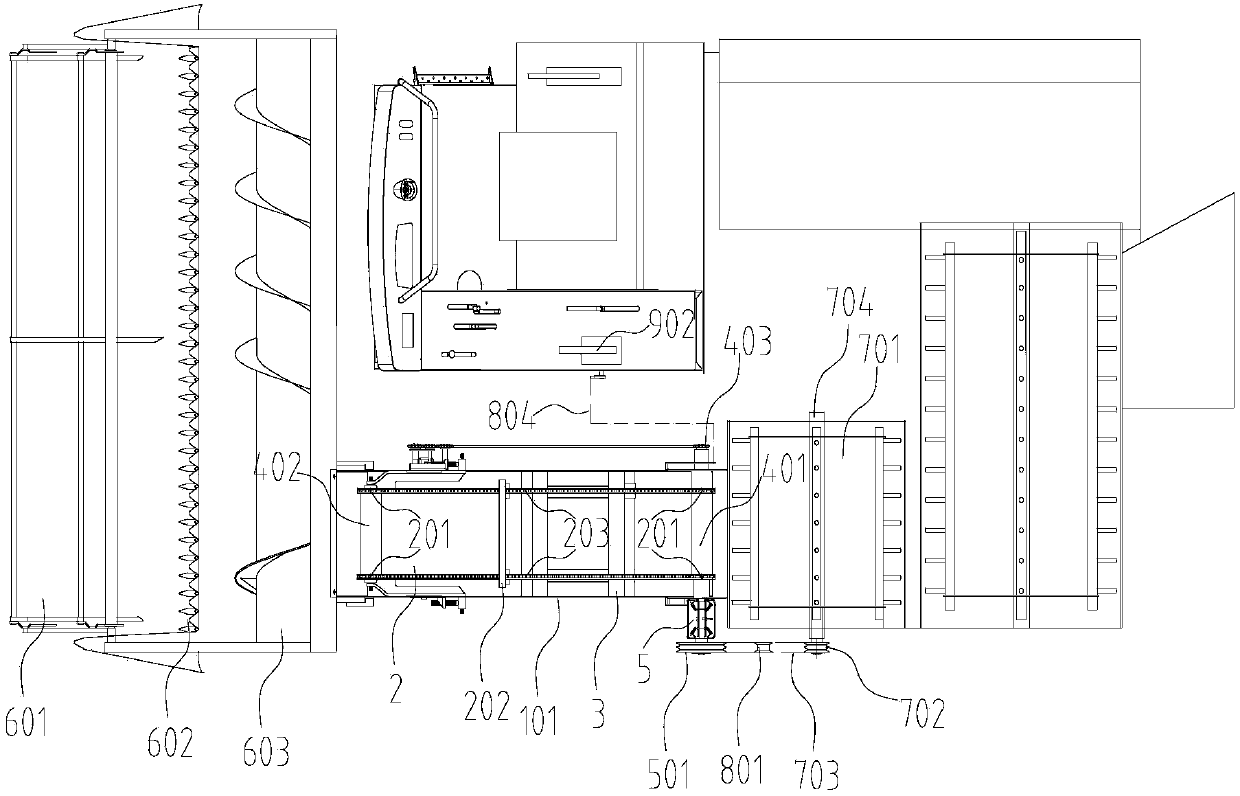

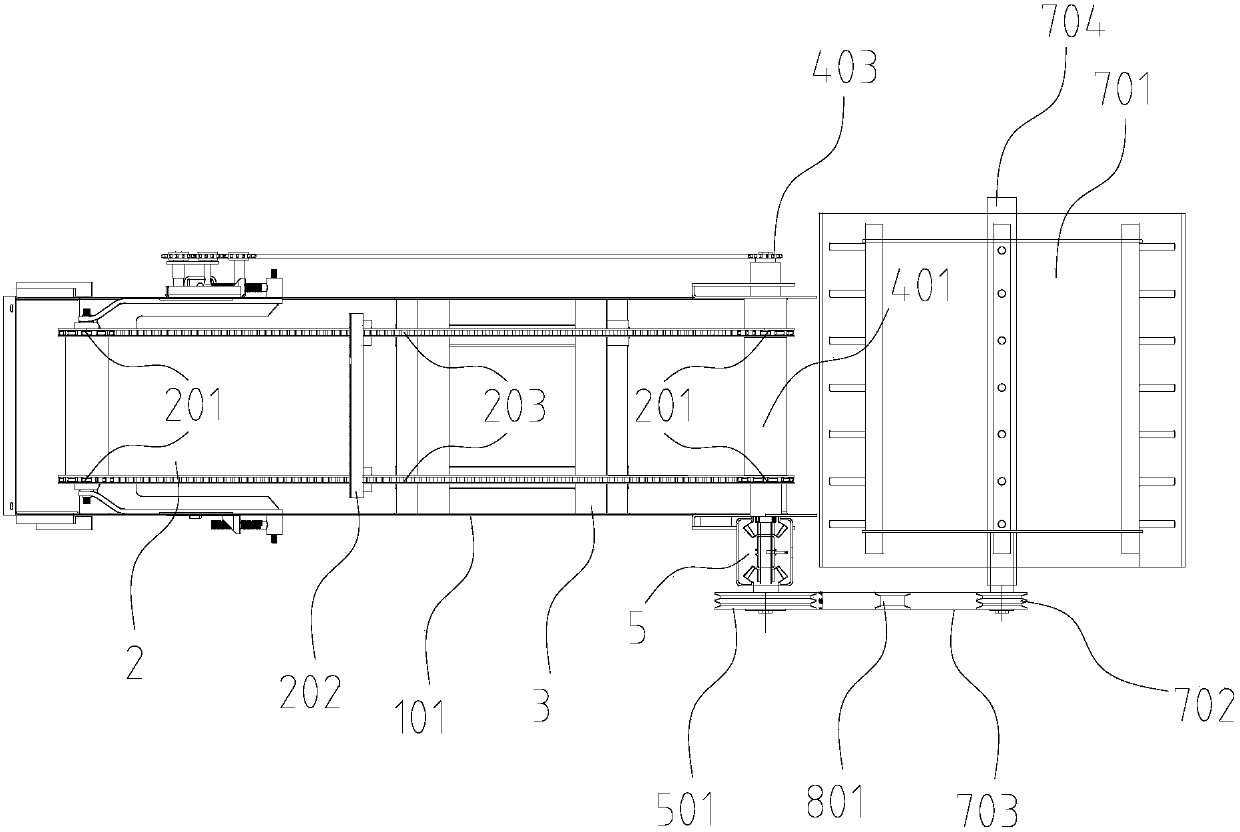

[0033] Such as Figure 1~3 As shown, a combine harvester conveying trough with the function of forward rotation conveying and reverse grass removal, including a conveying trough housing 1, a chain rake 2, a supporting plate 3, a transmission and a tensioning device; the conveying trough housing 1 The input end is connected to the feeding port of the combine harvester header feeding device 6, and the output end is connected to the feeding port of the combine harvester threshing device 7; the chain rake 2 includes a power input shaft 401 and a power output shaft arranged on the conveying trough The conveying sprocket 201 on the 402, the conveying sprocket 201 is meshed with the circular conveying chain 203 with rake teeth 202, and the rake teeth 202 are evenly distributed on the conveying chain 203; The middle of the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com