Transplanter end executor

A technology of end effector and actuator, which is applied in the direction of transplanting machinery, planting methods, applications, etc., can solve the problem of complex four-finger structure, comprehensive performance affecting the working efficiency of transplanting machine and the success rate of transplanting, and the inability to plant different seedlings Flexibility and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

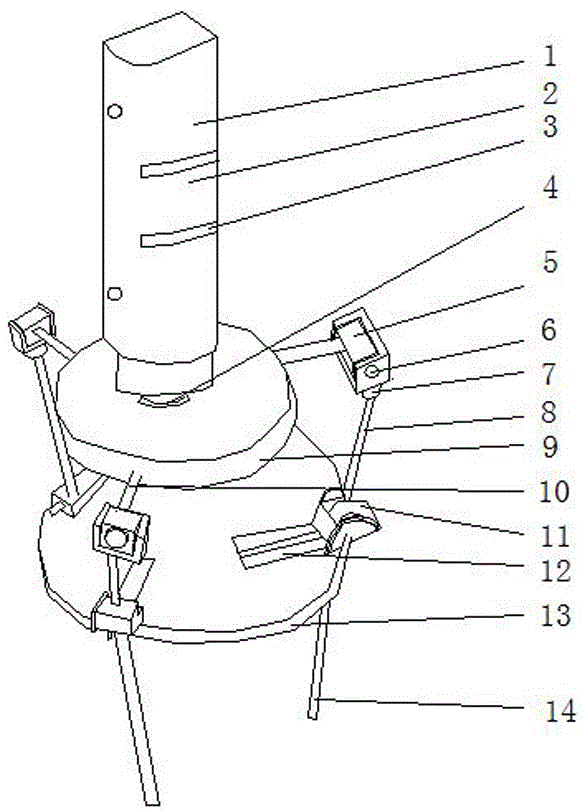

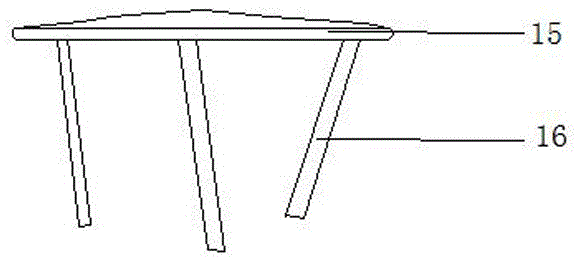

[0015] refer to Figure 1-2 , an end effector for a transplanting machine, comprising an actuator main body 2, a moving plate 9 and a transplanting fixed pointer plate 15, an air tank 1 is installed directly above the actuator main body 2, and an air tank lock is installed in the middle of the actuator main body 2 Tighten the nut 4, a moving plate 9 is installed in the middle of the actuator body 2, a slider 5 is installed around the actuator body 2, an indexing device 11 is installed under the actuator body 2, and a fixed disk 13 is installed directly below the actuator body 2, A fixed plate connecting rod 8 is installed in the middle of the actuator main body 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com