Stator punching sheet and electric motor

A stator punching and stator technology, applied in electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., can solve the problems of reducing the magnetic flux of the motor, reducing the output torque capacity of the motor, affecting the efficiency of the motor, etc. The effect of reducing torque ripple and improving the average value of electromagnetic torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

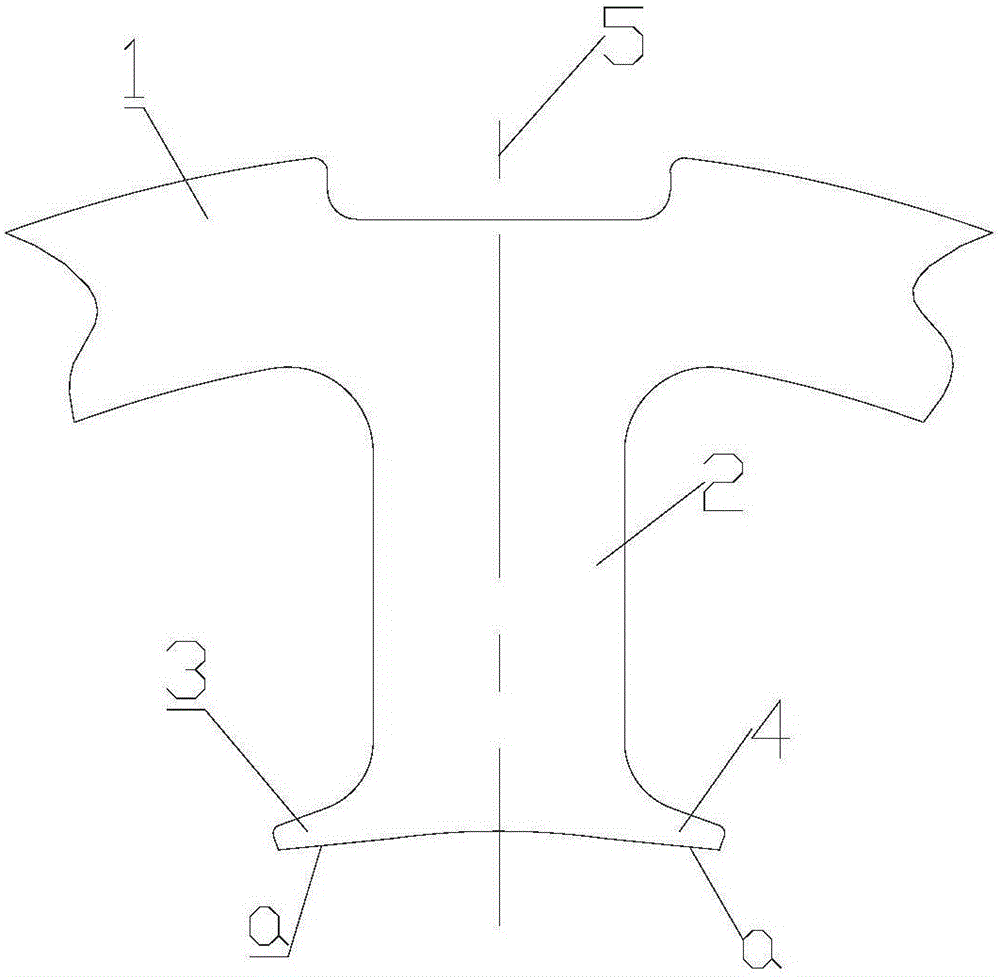

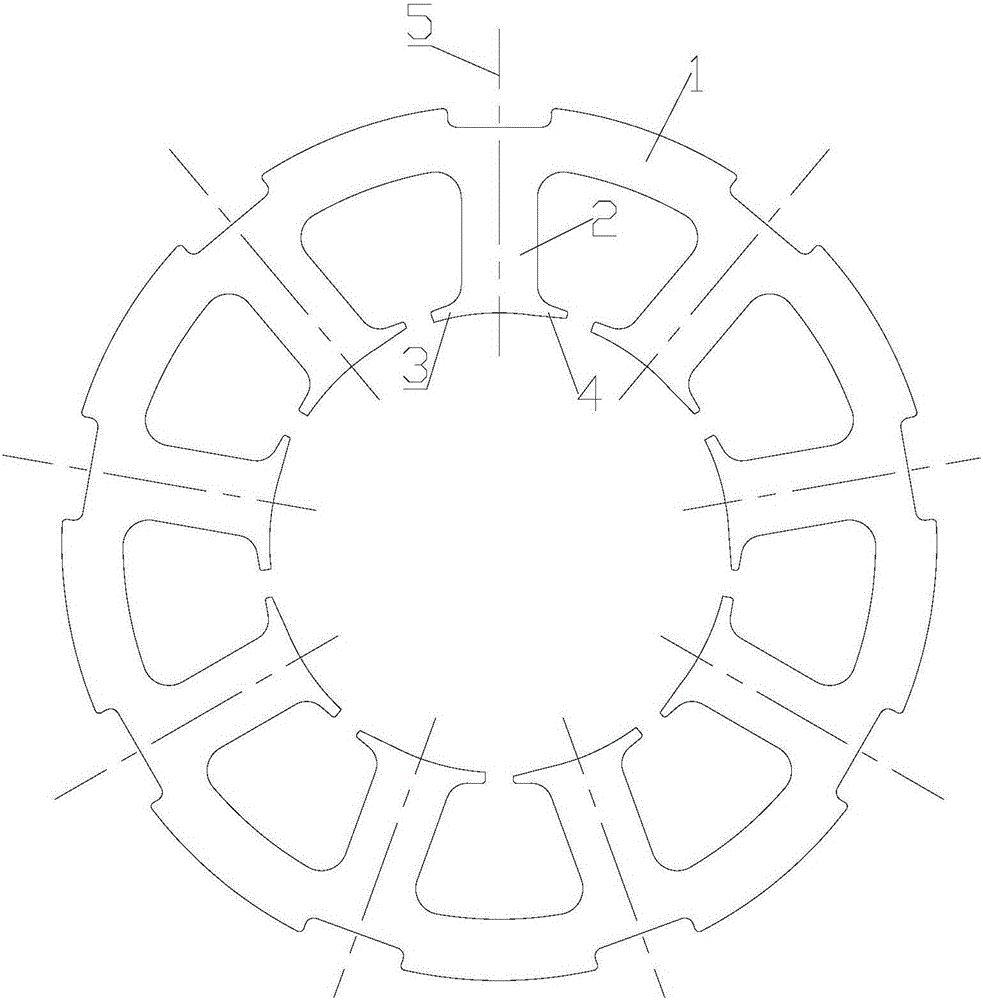

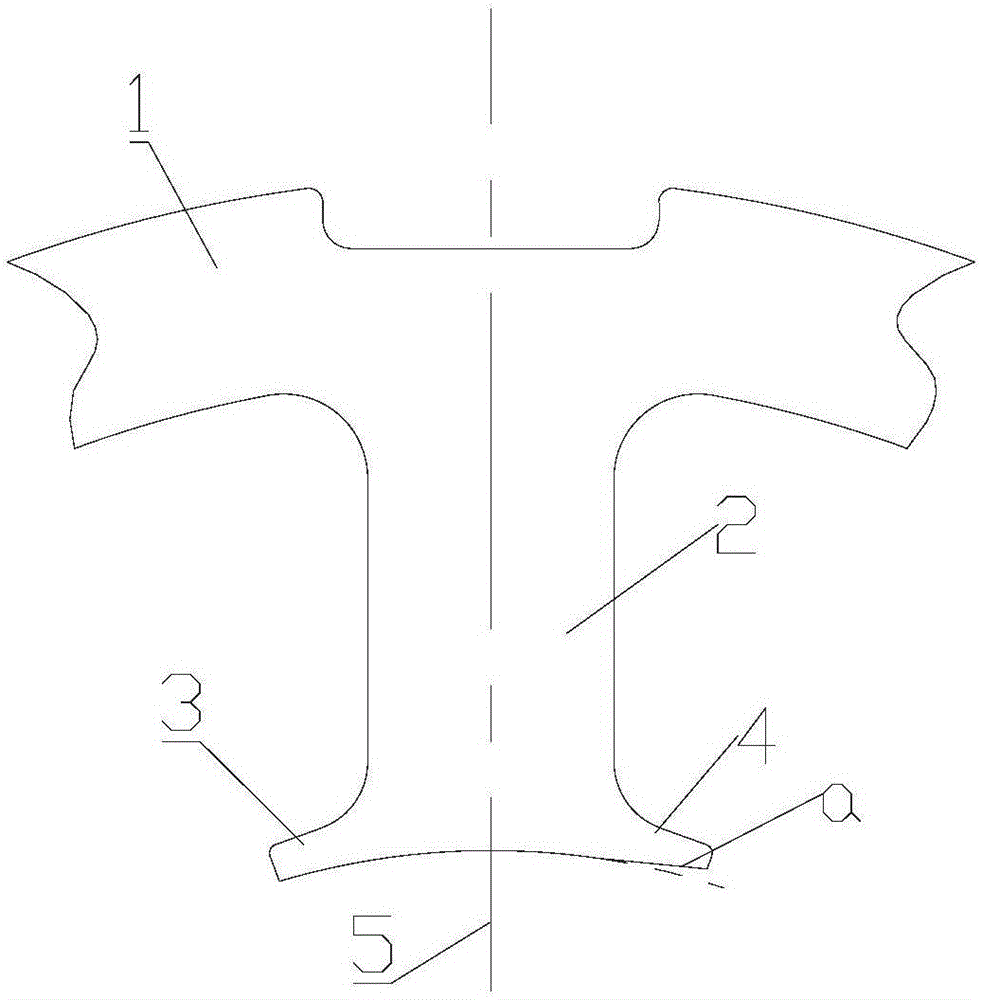

[0026] In the prior art, the tooth shoe of each stator tooth in the stator punch is arranged symmetrically with respect to the center line of the stator tooth, that is, the relationship is a mirror image with respect to the center line. In order to reduce the torque ripple of the motor, the edge trimming of the tooth shoe is usually used The structure weakens the harmonics of the air gap magnetic field, but at the same time reduces the effective magnetic flux of the motor, making the output of the motor smaller. Due to the existence of air-gap flux density harmonics, the electromagnetic torque of the motor is a pulsating wave with peaks and troughs. The difference between the peaks and troughs represents the torque ripple of the motor. If the trough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com