Surface-mounted electrical connection terminal

A surface mount, electrical connection technology, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problem that movable parts cannot move elastically, can no longer function as contact terminals, and have low protruding height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

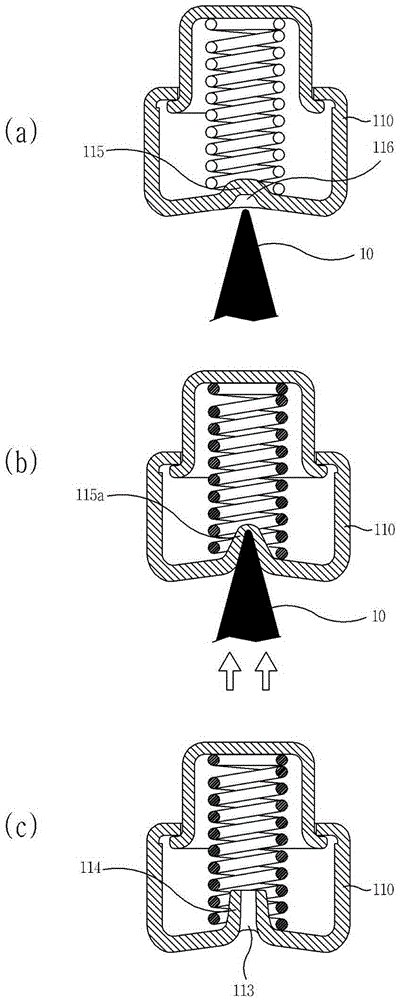

[0042] The surface mount type electrical connection terminal according to the embodiment of the present invention will be specifically described below with reference to the accompanying drawings.

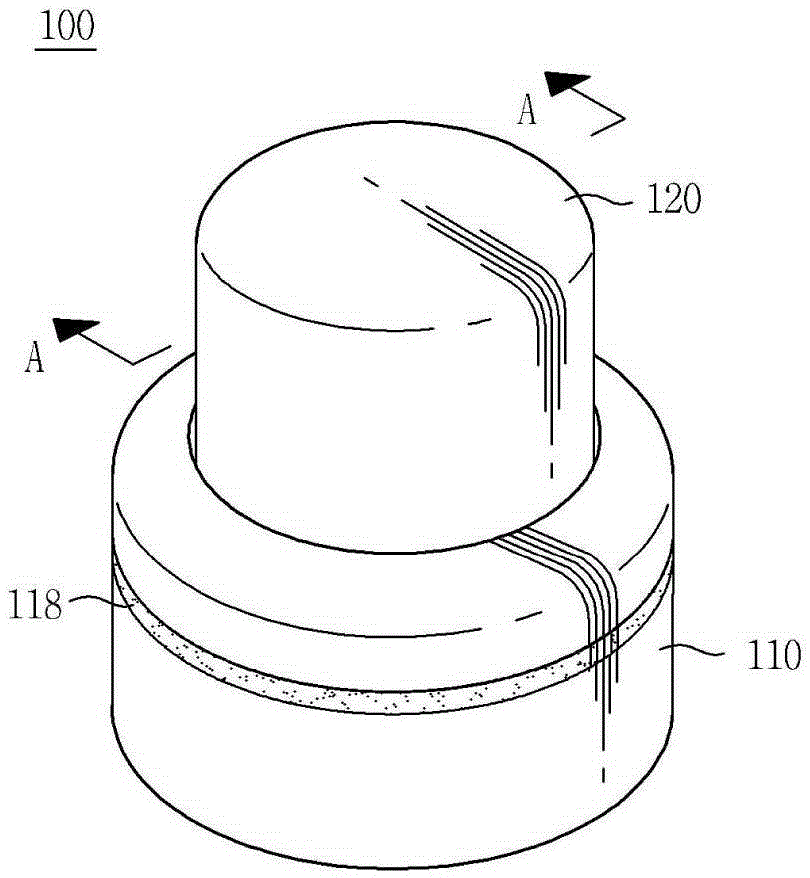

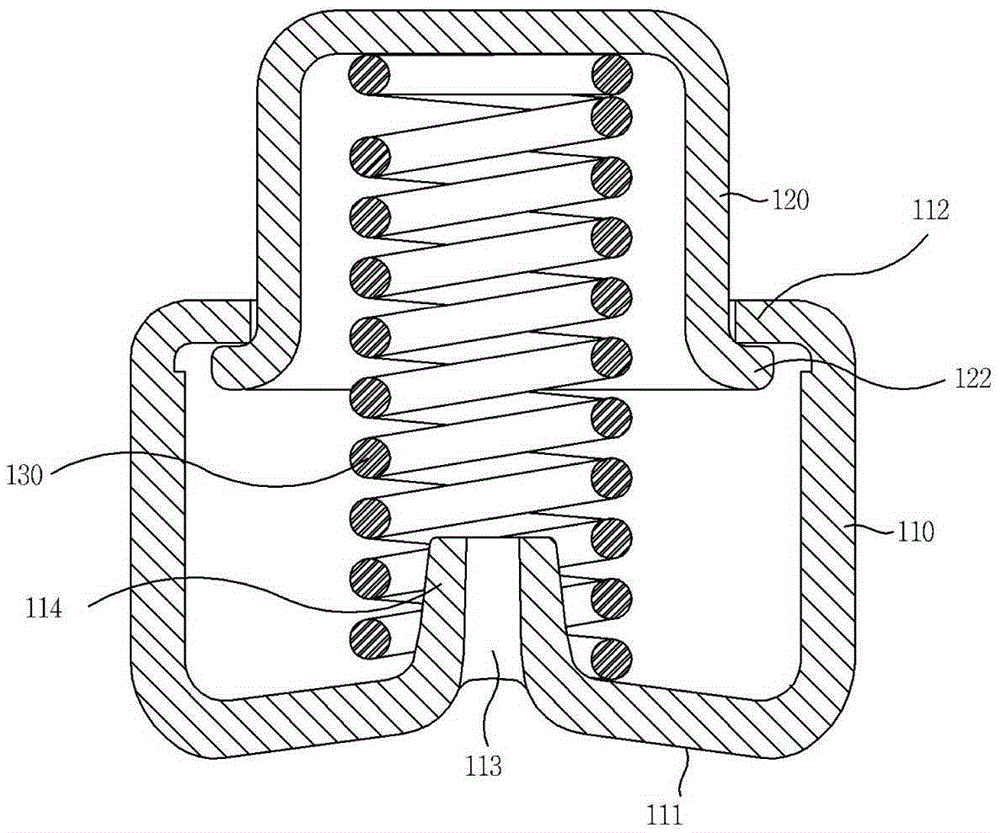

[0043] figure 1 is a perspective view showing a surface mount type electrical connection terminal according to an embodiment of the present invention, figure 2 is along figure 1 Cutaway view of A-A.

[0044] The electrical connection terminal 100 is composed of a metal fixed part 110, a metal movable part 120 slidably combined with the fixed part 110, and providing elasticity and elastic restoring force so that the movable part 120 is inserted into the fixed part 110. The spring 130 that elastically slides below constitutes.

[0045] The electrical connection terminal 100 is located between opposing conductive objects, has elasticity, and electrically connects the objects. For example, the opposite conductive object can be a circuit board and an antenna. At this time, the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com