In-service inspection system and method for storage tank floor based on magnetic horizontal shear wave

A technology of horizontal shear wave and storage tank bottom plate, which is applied in the direction of measuring device, solid analysis using sound wave/ultrasonic wave/infrasonic wave, material analysis using sound wave/ultrasonic wave/infrasonic wave, etc., which can solve the problem of low detection efficiency and high delay accuracy requirements , to achieve complex issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

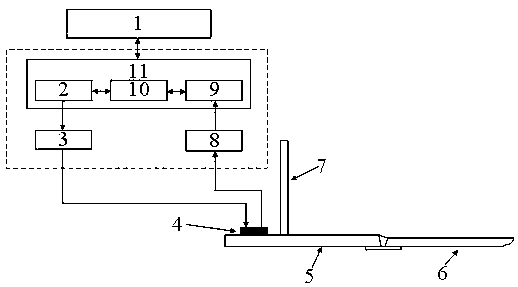

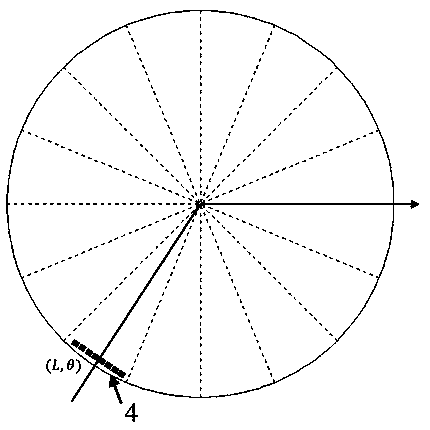

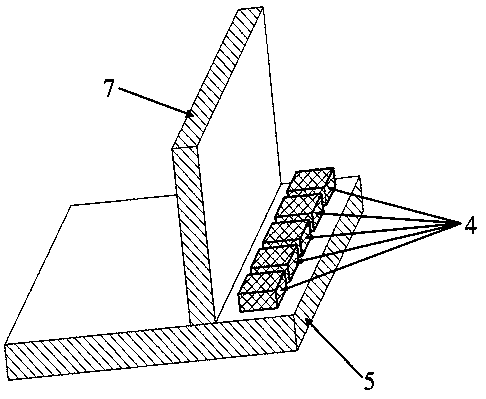

[0042] Such as figure 1As shown, a storage tank floor in-service detection system based on magnetically induced horizontal shear waves, the system includes a host computer 1, a multi-channel signal control and processing module 11, a power amplification module 3, a preamplification module 8 and a switch energy device array 4; multi-channel signal control and processing module 11 is composed of multi-channel excitation signal generation unit 2, multi-channel echo signal processing unit 9 and timing control unit 10; upper computer 1 is connected with multi-channel signal control and processing module 11 , the multi-channel excitation signal generating unit 2 is connected to the power amplification module 3, the power amplification module 3 is connected to the transducer array 4, and the excitation signal through power amplification and timing adjustment is input into the transducer array 4, and the transducer The array 4 is connected to the pre-amplification module 8, the pre-am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com