A kind of method for preparing rubber plasticizer from vegetable oil

A technology of rubber plasticizer and vegetable oil, which is applied in the field of plasticizers, can solve problems such as difficult realization of industrial production, and achieve the effects of improving reaction safety, increasing initial reaction speed, and sufficient epoxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

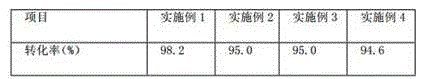

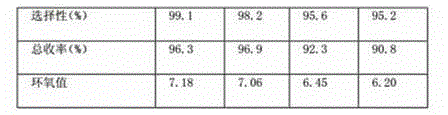

Examples

Embodiment 1

[0041] (1) Preparation of peroxy intermediates: Mix the mixed acid catalyst including organic acid (acetic acid) and strong acid (98wt% concentrated sulfuric acid and 732 resin) evenly, the mass ratio of organic acid and strong acid in the mixed acid catalyst is 6:3, stir and mix the peroxyacid stabilizer and 30wt% hydrogen peroxide evenly, and add the mixed acid catalyst dropwise to the mixed solution of the peroxyacid stabilizer and hydrogen peroxide at a temperature of 36°C. The peroxyacid stabilizer includes The mass ratio of ethylenediaminetetraacetic acid and potassium sodium tartrate is 1:0.2, the amount of mixed acid catalyst and peroxyacid stabilizer is 6% and 4% of pure hydrogen peroxide, respectively, after the addition is completed, stand at 36°C for reaction 10h to obtain a mixed solution of the peroxy intermediates.

[0042] (2)) Epoxidation reaction: add an epoxidation stabilizer to soybean oil, the epoxidation stabilizer includes urea, ethylenediaminetetraaceti...

Embodiment 2

[0044] (1) Preparation of peroxy intermediates: Mix the mixed acid catalyst including organic acid (formic acid and acetic acid) and strong acid (98wt% concentrated sulfuric acid and aluminum sulfate) evenly, and the mass ratio of organic acid and strong acid in the mixed acid catalyst is 16:6, stir and mix the peroxyacid stabilizer and 80wt% hydrogen peroxide evenly, and add the mixed acid catalyst dropwise to the mixed solution of the peroxyacid stabilizer and hydrogen peroxide at a temperature of 26°C. The peroxyacid stabilizer includes The mass ratio is 6:0.6 of ethylenediaminetetraacetic acid and potassium sodium tartrate. The added amount of the mixed acid catalyst and peroxyacid stabilizer is respectively 12% and 6% of the hydrogen peroxide. After 24 hours of reaction, a mixed solution of the peroxy intermediate was obtained.

[0045] (2) Epoxidation reaction: add an epoxidation stabilizer to soybean oil, and the epoxidation stabilizer includes urea, ethylenediaminetetr...

Embodiment 3

[0047] (1) Preparation of peroxy intermediate: Mix the mixed acid catalyst including organic acid (formic acid) and strong acid (phosphoric acid and 732 resin) evenly, the mass ratio of organic acid and strong acid in the mixed acid catalyst is 10:4, Stir and mix the peroxyacid stabilizer and 60wt% hydrogen peroxide evenly, and add the mixed acid catalyst dropwise to the mixed solution of the peroxyacid stabilizer and hydrogen peroxide when the temperature is 30° C., the peroxyacid stabilizer The agent includes ethylenediaminetetraacetic acid and potassium sodium tartrate with a mass ratio of 3:0.3, and the addition amounts of the mixed acid catalyst and peroxyacid stabilizer are respectively 10% and 3% of hydrogen peroxide. Stand for reaction for 16h to obtain the mixed solution of the peroxygen intermediate.

[0048] (2) Epoxidation reaction: add an epoxidation stabilizer to linseed oil, the epoxidation stabilizer includes urea, ethylenediaminetetraacetic acid, potassium sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com