Wire inlaying worktable

A workbench and countertop technology, applied in workbenches, manufacturing tools, etc., can solve the problem of single function of the filigree workbench, and achieve the effect of a reasonable lighting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a further understanding and understanding of the structural features and the achieved effects of the present invention, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

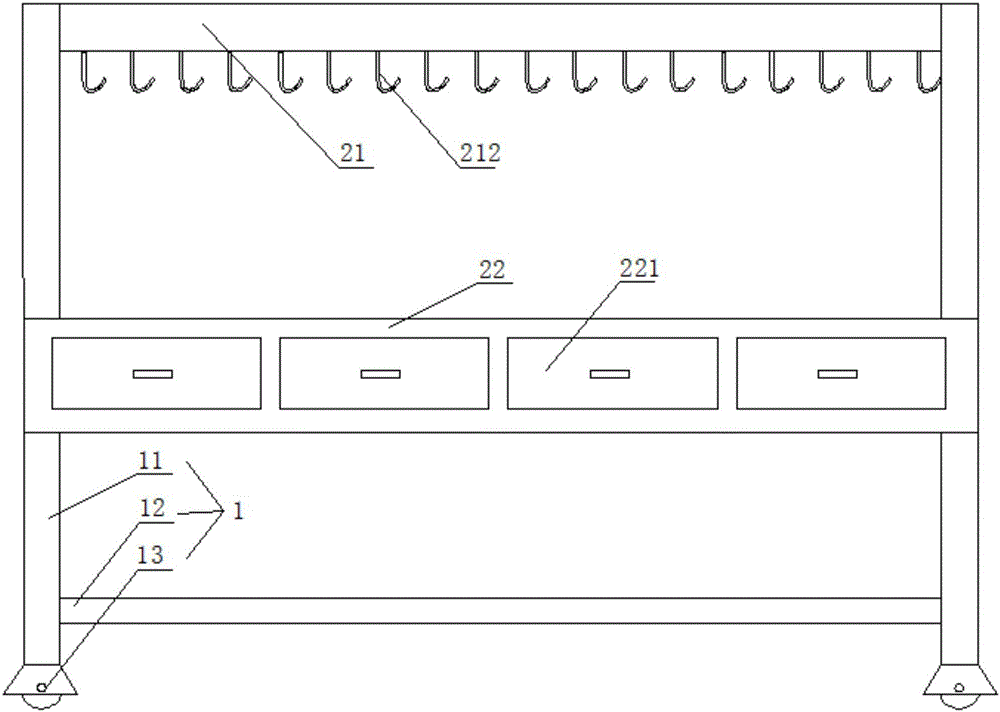

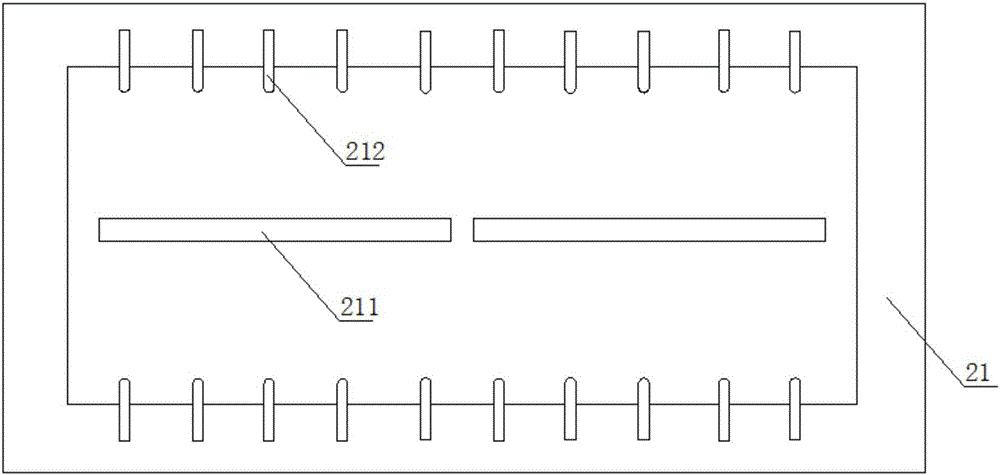

[0017] Such as figure 1 As shown, a filigree workbench includes a frame body 1, a top cover 21 is fixed on the top of the frame body 1; a table 22 with a plurality of drawers 221 is fixed in the middle of the frame body 1; the lower surface of the top cover 21 A plurality of lighting lamps 211 and hooks 212 are provided. The height of the table top 22 is generally the height that is convenient for filigree after the operator sits down.

[0018] Both the top cover 21 and the table top 22 provided by the present invention are rectangular. The frame body 1 includes uprights 11 fixed at the four corners of the top cover 21 and the table top 22 ; in order to make the workbench more stable, horizontal tie rods 12 are arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com