Centralized tool changer system

A tool magazine and tool technology, used in clamping, supporting, positioning devices, etc., can solve the problems of complex structure and large space occupation, and achieve the effects of flexible movement, stable movement and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

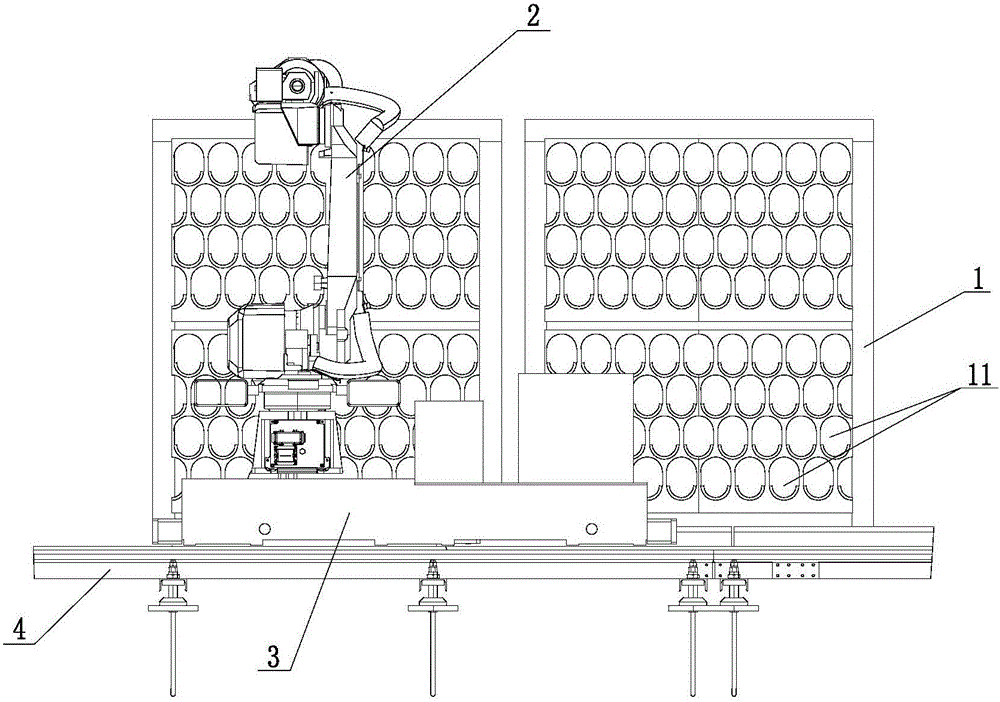

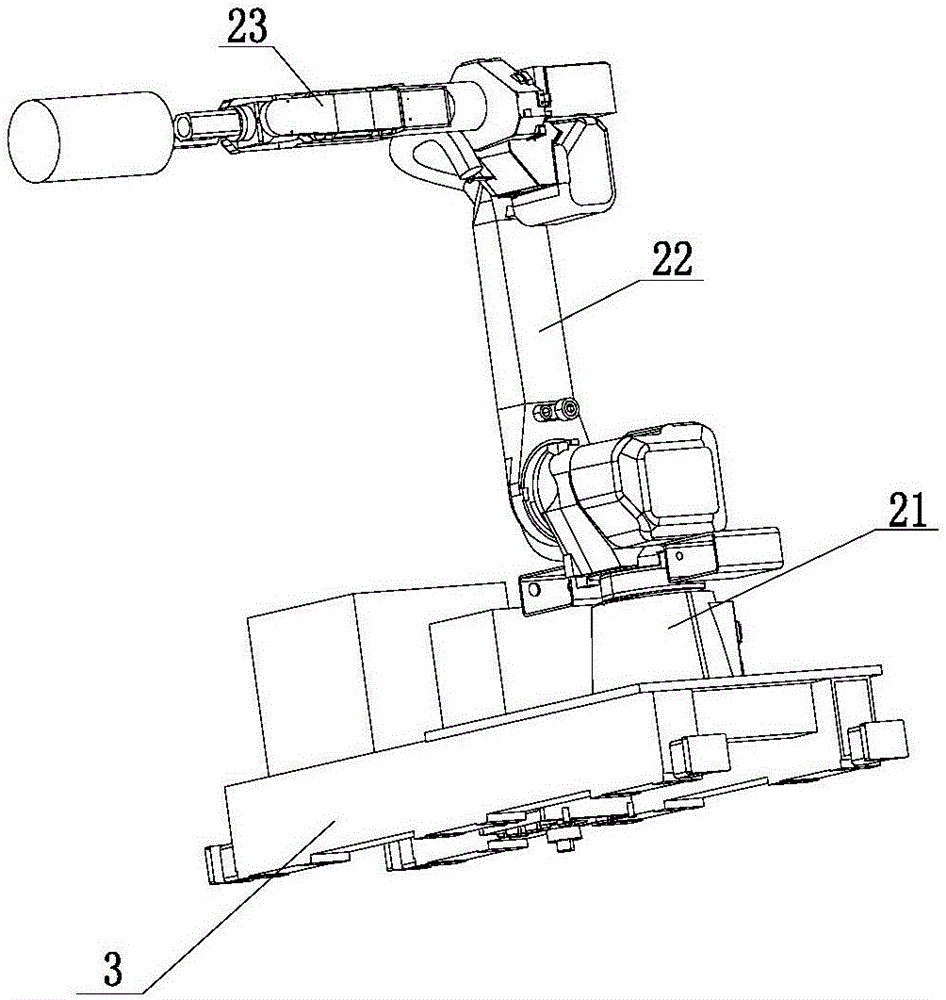

[0013] Such as Figure 1 ~ Figure 2 As shown, the centralized tool magazine system of the present invention includes an operating robot 2 for grabbing tools, a shuttle car 3 for sliding the operating robot 2, and a tool magazine 1 for placing knives. A tool placement cavity 11 for placing tools and arranged in a matrix; the shuttle car 3 is driven by a drive motor to slide on the slide rail 4, and the operating robot 2 grabs the tool on the tool magazine 1 and transports it through the shuttle car 3 Go to the main machine to change the tool and store the worn tools on the main machine. Specifically, the operating robot 2 includes a rotating bracket 21, a swinging bracket assembly 22, and a manipulator assembly 23. The rotating bracket 21 is installed on the slide table of the shuttle car 3 and driven to rotate by a rotating drive mechanism. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com