Preparation method of pech/pvdf anion exchange membrane based on semi-interpenetrating polymer network

An anion exchange membrane and polymer technology, applied in the field of preparation of PVDF/PECH anion exchange membrane based on semi-interpenetrating network, can solve the problems of easy water absorption, limit the practical application of electrodialysis technology, etc. The effect of suitable ion exchange content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

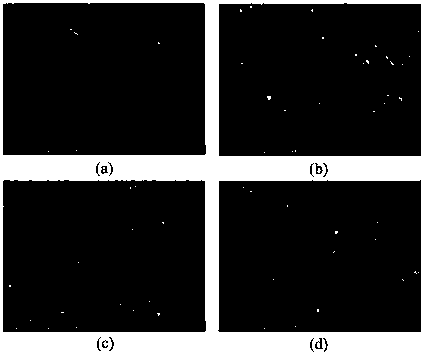

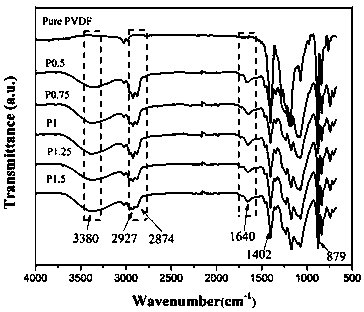

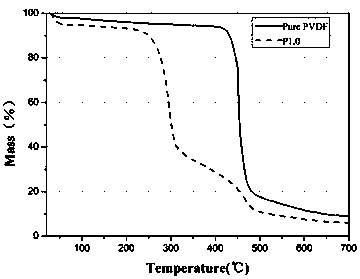

[0026] Accurately weigh 1g of polyepichlorohydrin and 0.5g of vinylidene fluoride in 25ml of dimethyl sulfoxide (DMSO), stir at 80°C for 3 h and dissolve to obtain a milky white mixture. Add 0.6 g of triethylenediamine (DABCO) to the resulting mixed solution and stir for 30 min to obtain a light yellow transparent solution. Vacuum defoaming. Then pour it on a clean glass plate and scrape the film with a spatula, and dry it in vacuum at 60°C for 24 hours. The membrane was taken out and soaked in deionized water for a period of time, so that the membrane glass plate fell off naturally, and the membrane was washed with deionized water. Then immerse the obtained membranes in 0.5mol / L, 1mol / L, and 1.5mol / L trimethylamine aqueous solutions respectively, perform quaternization reaction at 25°C for 24 hours, wash repeatedly with deionized water, and finally soak in deionized water For later use.

Embodiment 2

[0028] Accurately weigh 1g of polyepichlorohydrin and 0.75g of vinylidene fluoride in 25ml of dimethyl sulfoxide (DMSO), stir at 80°C for 3 h and dissolve to obtain a milky white mixture. Add 0.6 g of triethylenediamine (DABCO) to the obtained mixed solution and stir for 30 min to obtain a light yellow transparent solution, which is defoamed in vacuum. Then pour it on a clean glass plate and scrape the film with a spatula, and dry it in vacuum at 60°C for 24 hours. Take the membrane out and soak it in deionized water for a period of time to make the membrane fall off naturally on the glass plate, and wash the membrane with deionized water. Then immerse the obtained membrane in 0.5mol / L, 1mol / L, 1.5mol / L trimethylamine aqueous solution, carry out quaternization reaction at 25°C for 24 hours, wash it repeatedly with deionized water, and finally soak it in deionized water spare.

Embodiment 3

[0030] Accurately weigh 1g of polyepichlorohydrin and 1.0g of vinylidene fluoride in 25ml of dimethyl sulfoxide (DMSO), stir at 80°C for 3 h and dissolve to obtain a milky white mixture. Add 0.6 g of triethylenediamine (DABCO) to the obtained mixed solution and stir for 30 min to obtain a light yellow transparent solution, which is defoamed in vacuum. Then pour it on a clean glass plate and scrape the film with a spatula, and dry it in vacuum at 60°C for 24 hours. The membrane was taken out and soaked in deionized water for a period of time, so that the membrane glass plate fell off naturally, and the membrane was washed with deionized water. Then immerse the obtained membrane in 0.5mol / L, 1mol / L, 1.5mol / L trimethylamine aqueous solution, carry out quaternization reaction at 25°C for 24 hours, wash it repeatedly with deionized water, and finally soak it in deionized water spare.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com