Start and control circuit of gas discharge lamp electronic ballast

A technology for electronic ballasts and gas discharge lamps, applied in the direction of electric light sources, electrical components, lighting devices, etc., can solve the problems of difficult start-up and control functions of analog circuits, and achieve the elimination of safety hazards, simple structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described with reference to the accompanying drawings and specific embodiments.

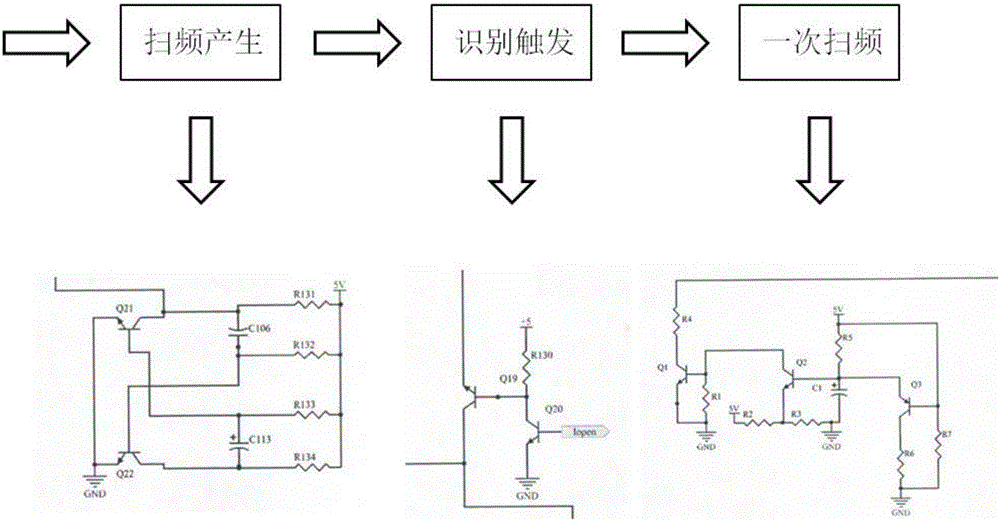

[0027] A start-up and control circuit of an electronic ballast for a gas discharge lamp, the start-up and control circuit includes a frequency sweep generating circuit I, an identification trigger circuit II, a primary frequency sweep circuit III and an enabling circuit IV;

[0028] The frequency sweep generating circuit I is used to generate a PWM wave whose frequency changes from high to low; the input end of the frequency sweep generating circuit I is connected to the control voltage, and the output end of the frequency sweep generating circuit I is connected to the input end of the identification trigger circuit II;

[0029] The identification trigger circuit II is used to eliminate the potential safety hazard of the ballast during normal operation by changing the circuit working state after sweeping the frequency to the resonance point and triggeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com