Transformer capable of increasing impedance

A technology of transformers and main transformers, applied in the field of transformers, can solve problems such as large capacity, unusable system disassembly, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0077] Example: SSFZ—50000 / 121 power transformer, high voltage 121±8×1.25%, medium voltage 36.75±2×2.5%, low voltage 10.5KV, oil-immersed and air-cooled, other parameters are based on GB / T 6451.

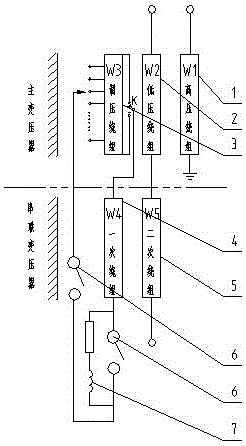

[0078] The original design as Figure ten As shown in VII, this scheme uses copper 14556KG, silicon steel sheet 24640KG, no-load loss: 35KW, load loss: 228KW. And during operation, an air-core reactor needs to be connected in series on the medium-voltage side, and an iron-core reactor should be connected in series on the low-voltage side.

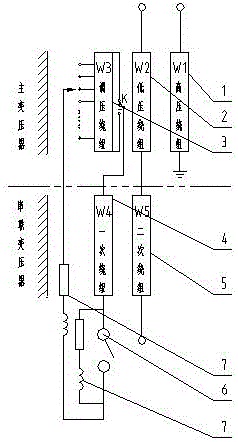

[0079] A transformer that can increase the impedance adopts Figure ten Eight principles. This scheme uses copper 12145KG, silicon steel sheet 25468KG, no-load loss: 34.4KW load loss: 217KW. During operation, a core reactor is connected in series on the voltage regulating side.

[0080] When the copper price is 50 yuan / KG and the silicon steel sheet is 24 yuan / KG, the new scheme saves 7.7% of the cost compared with the original design scheme, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com