Large wire harness sleeving special-purpose device

A special equipment and casing technology, applied in the manufacture of wire harnesses, electrical components, circuits, etc., can solve the problems of long operation time, increased difficulty of manual traction, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

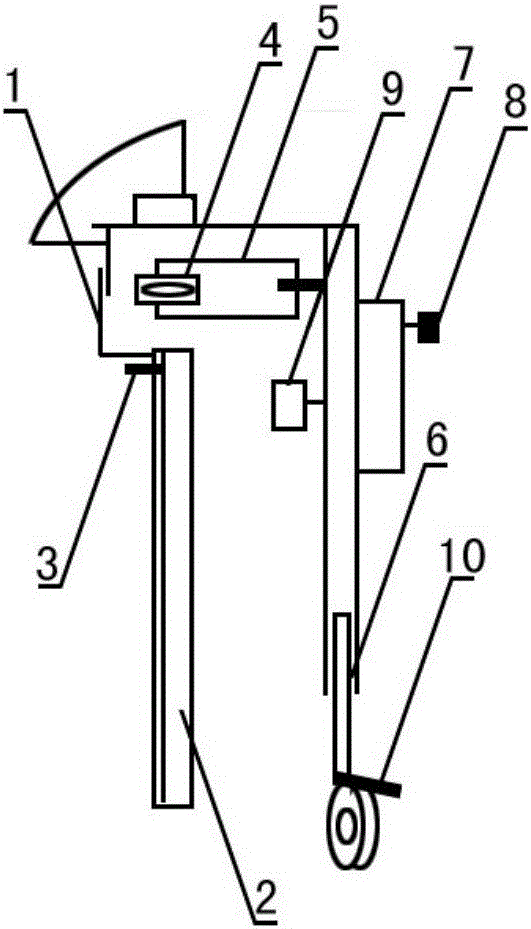

[0012] Embodiment: as shown in the accompanying drawing. A special equipment for large wire harness bushings, comprising a frame body (1), the frame body (1) has a unilateral mobile design, and a casing positioning structure is set on the left side, including a long empty tube device (2), a smoothing structure ( 3), the push wheel (4) and the horizontal cover device (5) are set on the upper end, and the lifting support column (6) is set on the right side of the frame body (1). When in use, start the electric device (7), and adjust the corresponding After the overall height of the parts, the casing is positioned in the empty pipe device (2), and the long wire is inserted into the groove of the push wheel (4) through the inlet to carry out the casing operation.

[0013] A special device for large wire harness bushings, a prompting device (8) is provided on the outside of a frame body (1), and the prompting information is displayed by sound or LED lights.

[0014] A special devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com