Rotary machine holographic diagnostics method based on frequency modulation information reconstruction

A technology of rotating machinery and diagnostic methods, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as the inability to directly obtain torsional vibration signals of rotating equipment, achieve intuitive and complete diagnostic results, and improve utilization The effect of efficiency and hardware cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

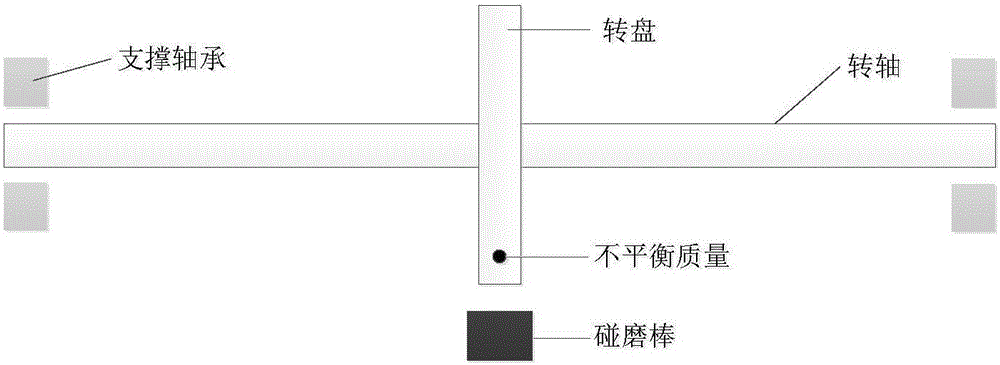

[0051] Embodiment 1, using the dynamics simulation signal of the rotor system for verification, and establishing the finite element model of the rotor system such as figure 1 As shown, the dynamic and static rubbing fault of the rotor is caused by the unbalance of the rotor. The dynamic and static rubbing fault simulation is carried out by changing the dynamic and static spacing. The basic parameters of the finite element model of the rotor system are shown in Table 1.

[0052] Table 1 Basic parameter table of the finite element model of the rotor system

[0053]

[0054] The element stiffness matrix, element mass matrix, and element gyro force matrix of the rotor system are as follows:

[0055] The element stiffness matrix is:

[0056] [ M e ] = E A l ...

Embodiment 2

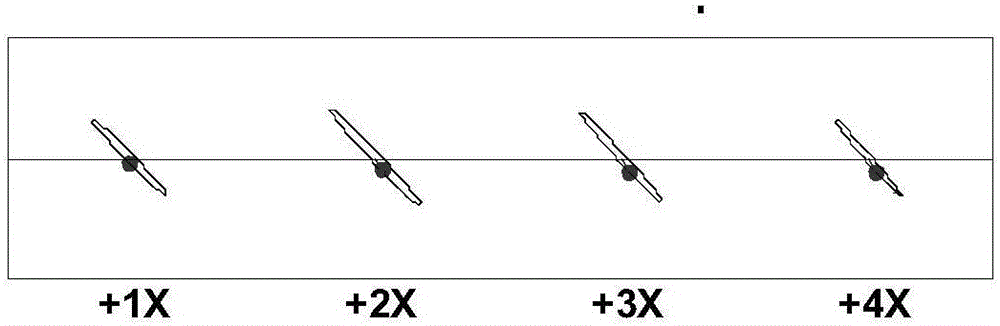

[0089] Example 2, through the Bentley RK4 rotor test bench for experimental verification, the structure diagram of the Bentley RK4 rotor test bench is as follows Figure 4 As shown, the diameter of the rotor is 10mm, the length is 550mm, and the front and rear support span is 325mm. Viewed from the drive end, the rotor system rotates in the counterclockwise direction, and two balancers for adding balance mass are arranged axially symmetrically in the rotor span. Disk, each disk weighs 0.8kg, 16 holes are equiangularly distributed along the circumference of the balance disk at a radius of 30mm for adding balance mass, the experiment simulates the dynamic and static friction fault of the rotor by adjusting the distance between the friction rod and the rotor, the experiment The rev is set at 1700rpm.

[0090] A method for holographic diagnosis of rotating machinery based on frequency modulation information reconstruction, comprising the following steps:

[0091] Step 1: Install ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com