Measurement method of turbine blade rotation angle based on level gauge

A technology for angle measurement and leveling, which is applied to measuring devices, measuring angles, instruments, etc., can solve the problems of inability to determine the exact position of the rotation centerline of the blade, the difficulty of accurately measuring the blade rotation angle, and the inaccuracy and deviation of the measurement value. Conducive to stable operation, simple operation and uniform blade angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

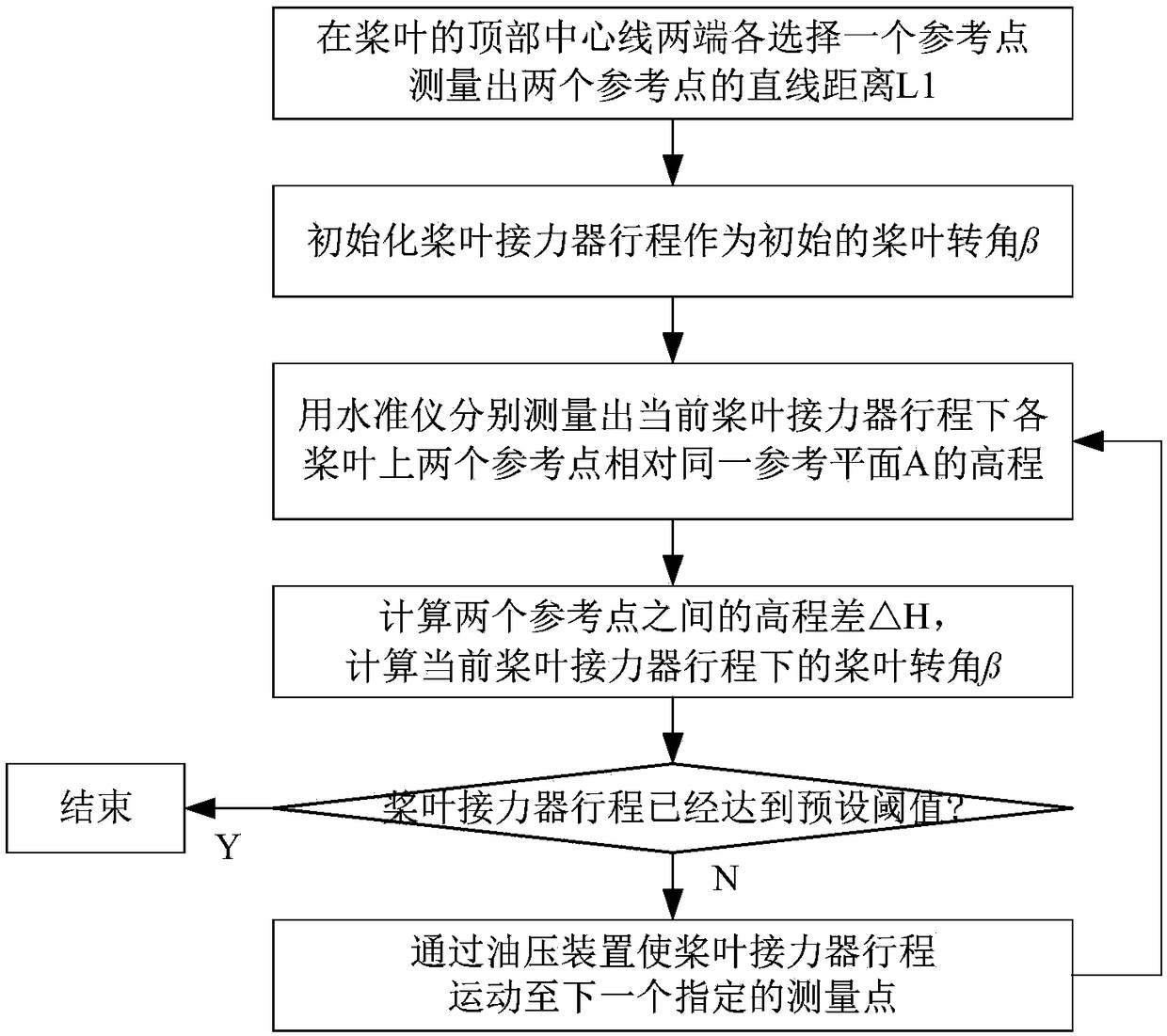

[0020] Such as figure 1 As shown, the steps of the water turbine blade rotation angle measurement method based on the level gauge in this embodiment include:

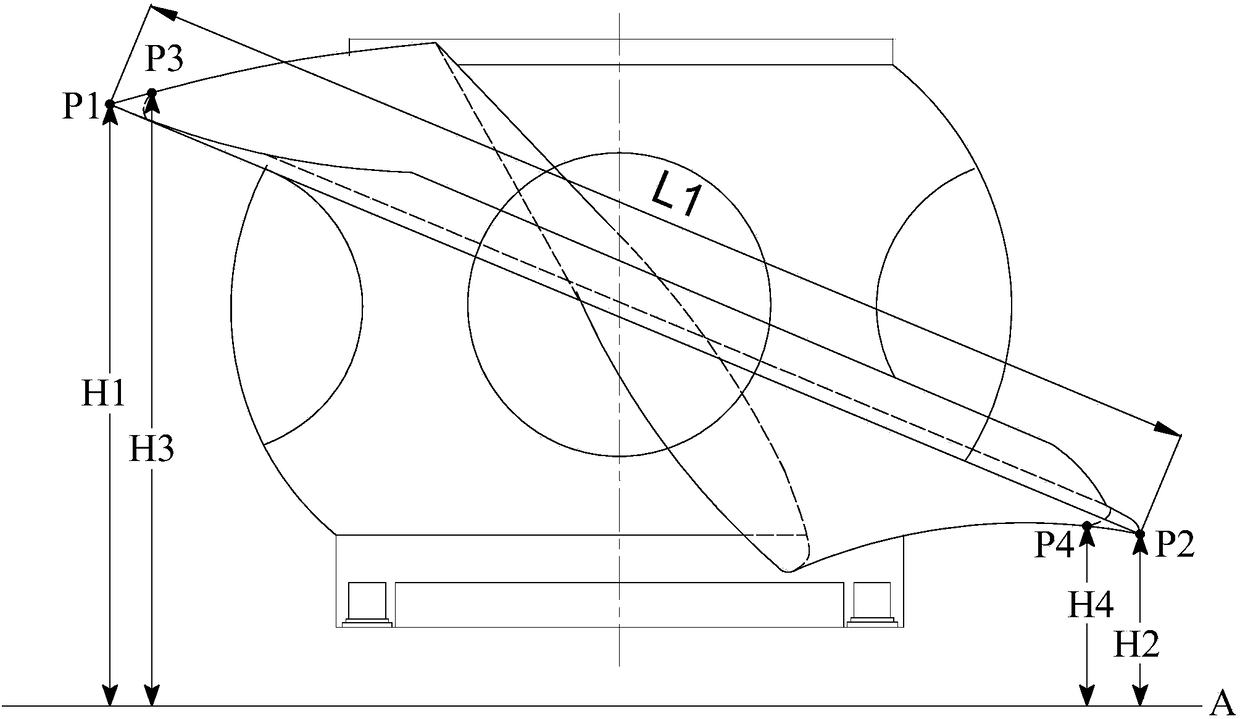

[0021] 1) Select a reference point at both ends of the top centerline of the blade, and measure the straight-line distance L1 between the two reference points;

[0022] 2) Initialize the stroke of the blade servomotor as the initial blade rotation angle β;

[0023] 3) Use a level to measure the elevations of the two reference points on each blade relative to the same reference plane A under the current stroke of the blade servomotor;

[0024] 4) Calculate the elevation difference △H between the two reference points, and calculate the blade rotation angle β under the current blade servo stroke according to the function β=arcsin(△H / L1), where △H represents the elevation of the two reference points difference, L1 represents the straight-line distance between two reference points;

[0025] 5) Judging whether the servomot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com