Drilling rock core level dip meter

A drilling core and measuring instrument technology, applied in angle/taper measurement and other directions, can solve the problems of undiscovered, difficult to ensure the accuracy of measurement results, and difficult to determine the layer inclination, etc., to achieve accurate readings, improve accuracy, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

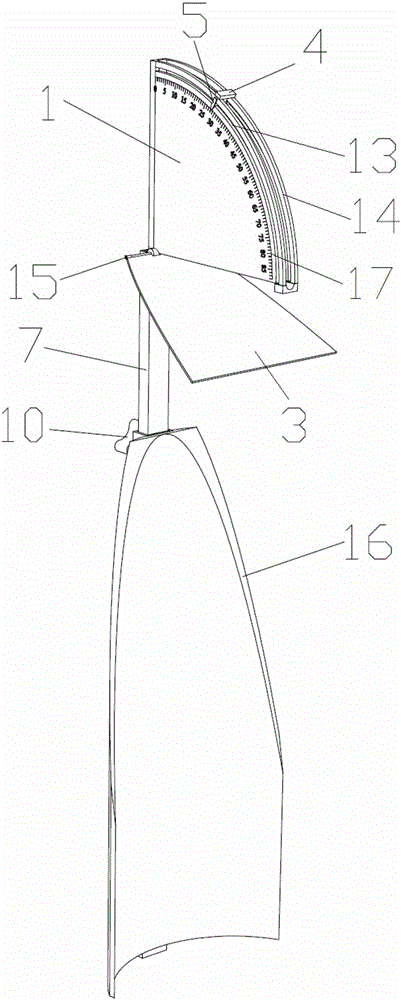

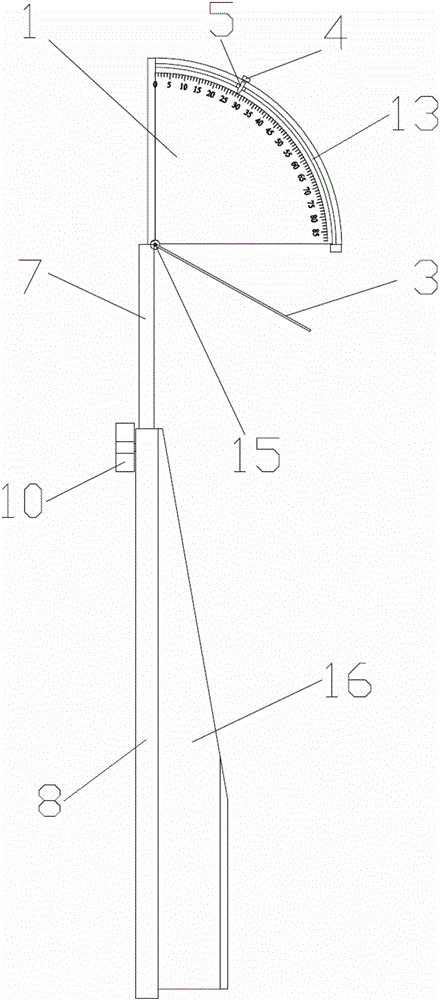

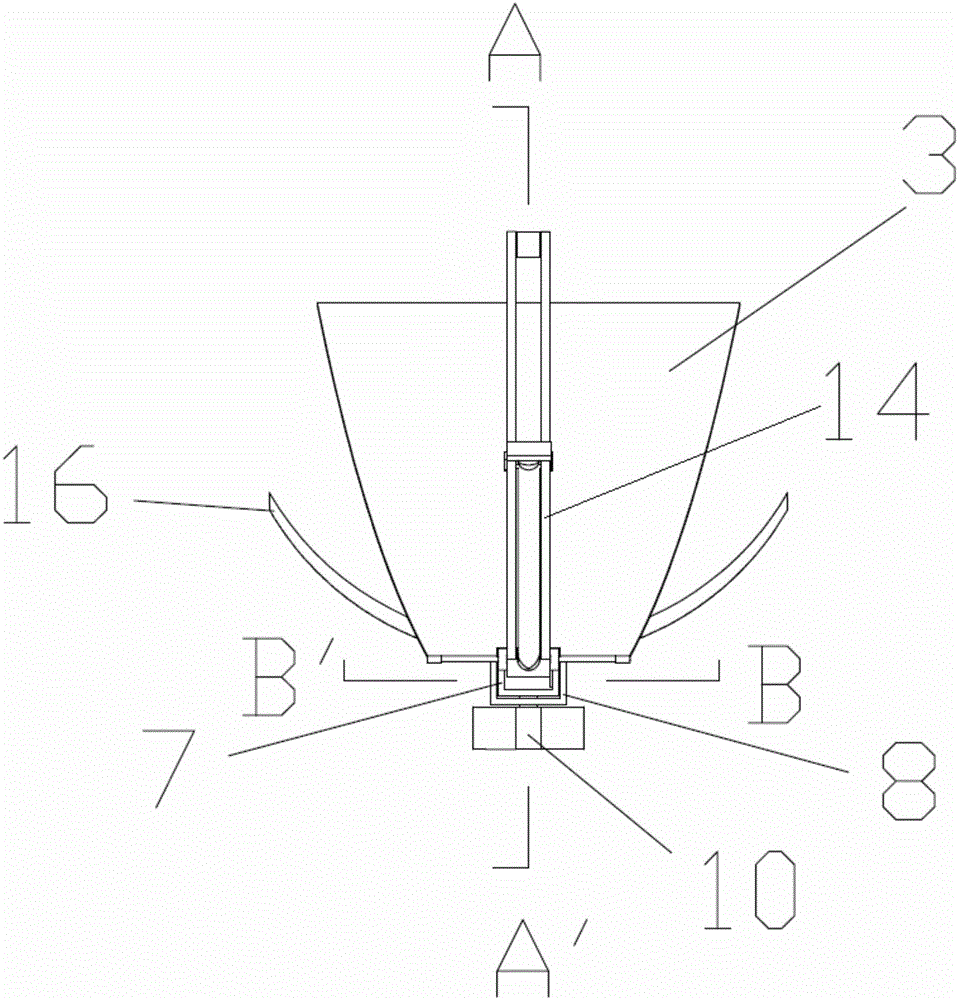

[0033] The drilling core layer inclination measuring instrument provided by the invention has a structure such as Figure 1 to Figure 3 As shown, including sequentially connected measuring unit, adjusting unit and core fixing assembly;

[0034] The measuring unit includes a reading plate 1, an indicator rod 2 and a bonding plate 3. The reading plate is a fan-shaped hollow structure, and an angle scale 17 is provided on the arc-shaped side of the reading plate, and an arc is provided on the arc-shaped side of the reading plate. Shaped card slot 14, indicating rod 2 is a cylindrical rod, and indicating rod 2 is located in the fan-shaped hollow inner cavity of the reading disc. There are semi-cylindrical slots on the two right-angle sides of the inner cavity of the read...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com