A Sealing Structure Applied to Economizer Ventilation Beam

A sealing structure and economizer technology, applied in engine sealing, feed water heater, preheating, etc., can solve the problems of large air leakage in the economizer section, affect boiler efficiency, poor sealing effect, etc., and achieve low welding difficulty , Good sealing effect, stable and safe operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

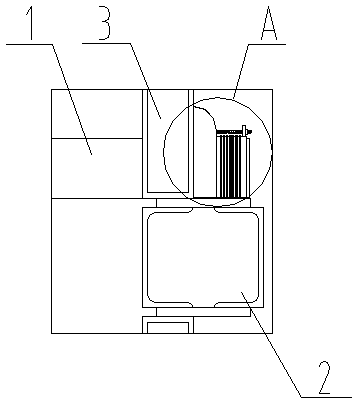

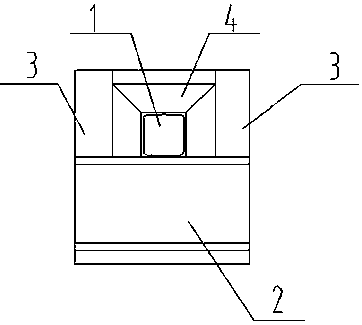

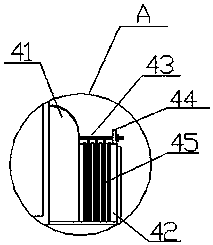

[0016] Such as Figure 1-3 As shown, a sealing structure applied to an economizer ventilation beam includes an economizer ventilation beam 1, a steel frame beam 2, an economizer guard plate 3 and a sealing device 4, and the economizer guard plate 3 is fixed On the steel frame beam 2, the expansion end of the economizer ventilation beam 1 passes through the economizer guard plate 3 and is arranged on the steel frame beam 2, and the sealing device is made of 2mm-3mm thick It is made of steel plate stamping, which is sleeved on the expansion end of the economizer ventilation beam 1 and welded with the economizer guard plate 3 and the steel frame beam 2 respectively; the sealing device 4 includes a bent part 41 , telescopic part 42 and limit nut 43, described bending part 41 and described telescopic part 42 are integrally formed, and the bending radius of described bending part 41 is 50mm; A plurality of reinforcing rings 45 are provided, and a limit block 44 is provided at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com