Industrial acidification system and method for offshore oil fields and oil-water wells

A factory-like, oilfield technology, applied in earthwork drilling, wellbore/well components, cleaning equipment, etc., can solve problems such as high risk of platform hoisting and installation, high cost of equipment relocation, and difficult resource organization, etc., to optimize personnel and equipment configuration, reduce relocation costs, relocation and hoisting risks, and save operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the factory acidizing system and method for oil and water wells in offshore oil fields of the present invention will be described in detail.

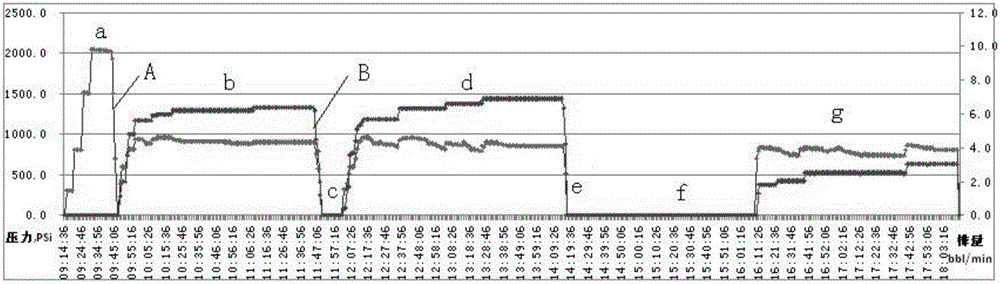

[0031] figure 1 A schematic construction layout diagram of a factory acidizing system for oil and water wells in an offshore oil field is shown according to an exemplary embodiment of the present invention.

[0032] Such as figure 1 As shown, according to an exemplary embodiment of the present invention, the industrialized acidizing system for oil and water wells in offshore oilfields includes an acid solution preparation unit 10 , an acidification construction unit 20 and a raffinate recovery unit 30 adjacent to each other. Among them, the acid liquid preparation unit 10 is used for the storage of raw materials and the preparation of the acidizing working fluid (hereinafter referred to as acid liquid), the acidizing construction unit 20 is used for carrying out acidizing construction operations on each oil and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com