Static sounding penetrating device with sleeve function

A static penetration and casing technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of test termination, increase penetration force of penetration equipment, equipment loss, etc., to ensure the success rate , large penetration depth, reducing the effect of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

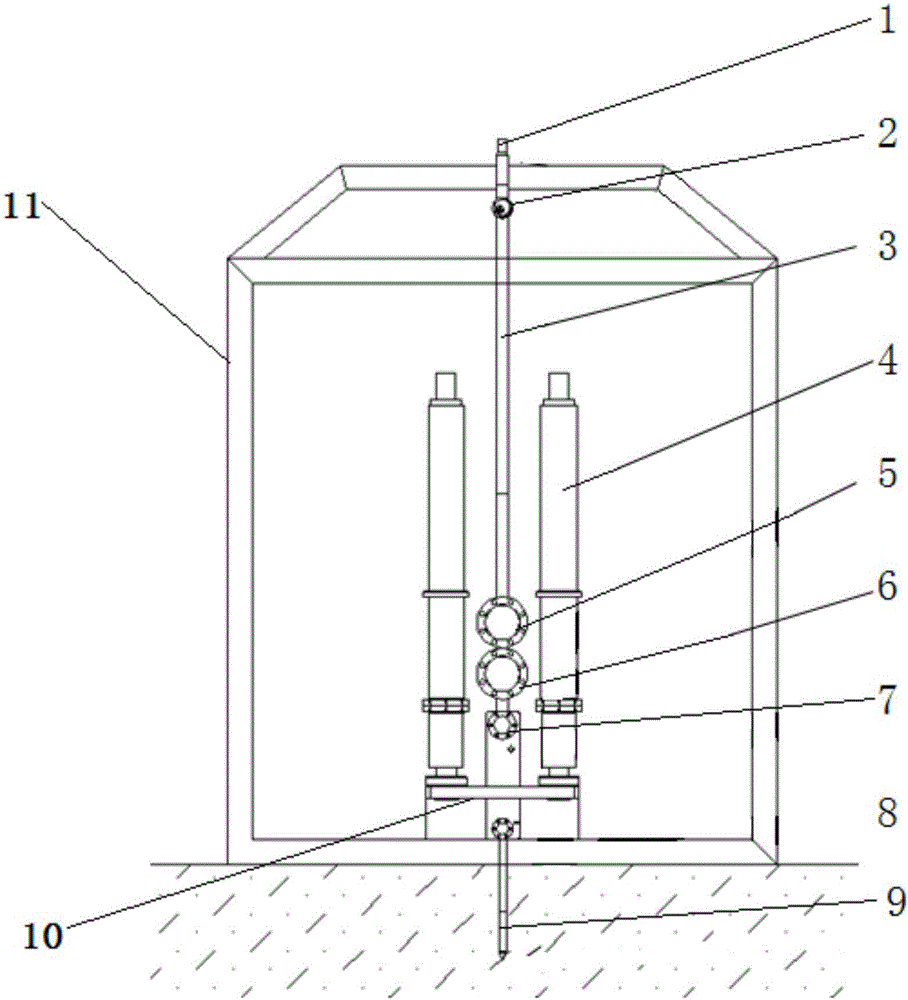

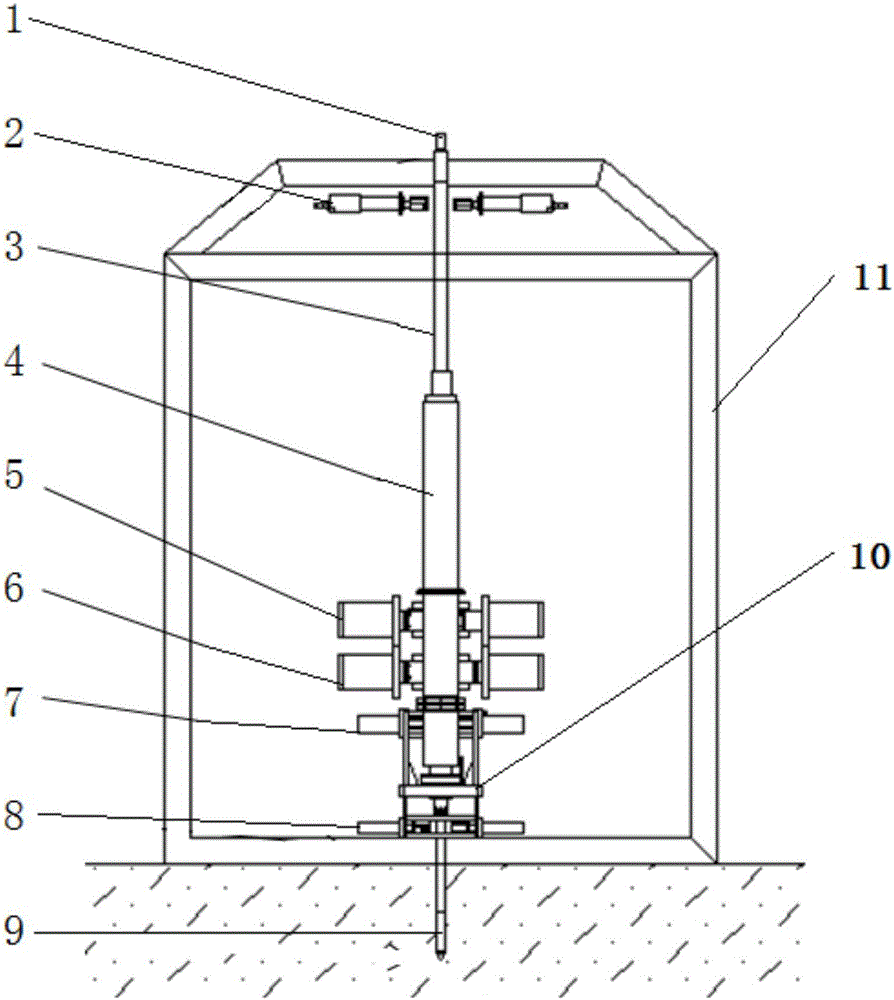

[0019] Such as Figure 1-2 As shown, a static penetrating device with casing function according to the embodiment of the present invention, the main frame body 11 is provided with a base 10 in the lower part of the main frame body 11, and the two sides of the base 10 are respectively installed with penetration oil cylinders 4. The bushing 3 is passed through the middle of the base 10, the probe rod 1 is inserted inside the bushing 3, and the lower end of the probe rod 1 is connected with the upper end of the static penetration probe 9. The probe rod 1 has a tubular structure, and multiple threads are cascaded during installation. The casing 3 is a tubular structure, and multiple threads are cascaded during installation. The inner diameter of the casing 3 is larger than the outer diameter of the probe rod 1. Pipe 3 passes through the middle.

[0020] The upper clamping cylinder 2 is arranged on the upper part of the casing 3, and is used to provide a fixed fulcrum when the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com