Center line deviation rectifying method for ballastless track of high-speed railway of roadbed segment

A ballastless track and high-speed railway technology, applied in tracks, track maintenance, roads, etc., can solve the problems of unfavorable on-site organization and management, poor construction control accuracy, low construction control accuracy, etc., to facilitate safe operation, high construction efficiency, The effect of fast development of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An embodiment of the present invention provides a method for rectifying and repairing the centerline of a settled ballastless track in a subgrade section of a high-speed railway. The method includes the following contents:

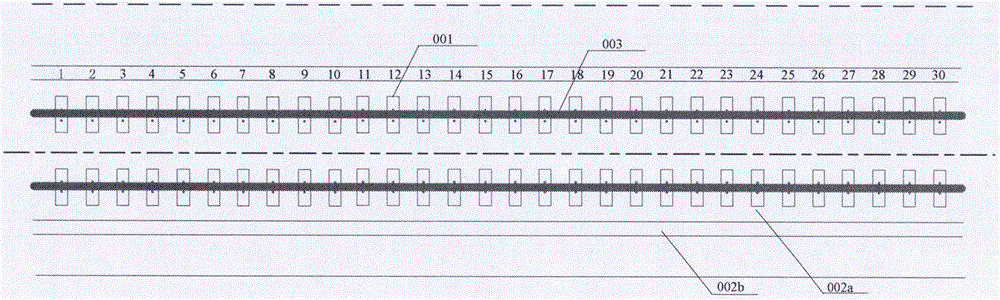

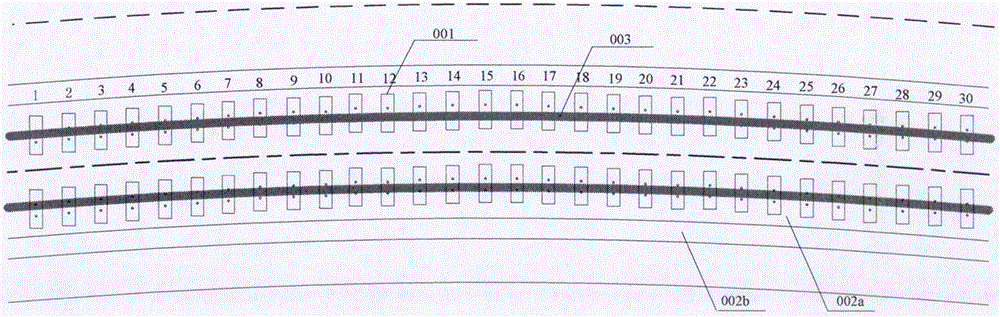

[0033] (1) Before lifting, use the total station and electronic level to measure the alignment of the ballastless track in a subgrade section, establish a measurement control network, and number each rail bearing platform, as shown in figure 1 with figure 2 As shown, according to the measurement results, combined with the center line deviation and settlement of the line, the design correction amount and design lift amount corresponding to the 1# to 30# rail platform (001) in the line correction section are determined, as shown in Table 1.

[0034] Table 1 Design correction amount and design lifting height of 1# to 30# rail bearing platform

[0035]

[0036]

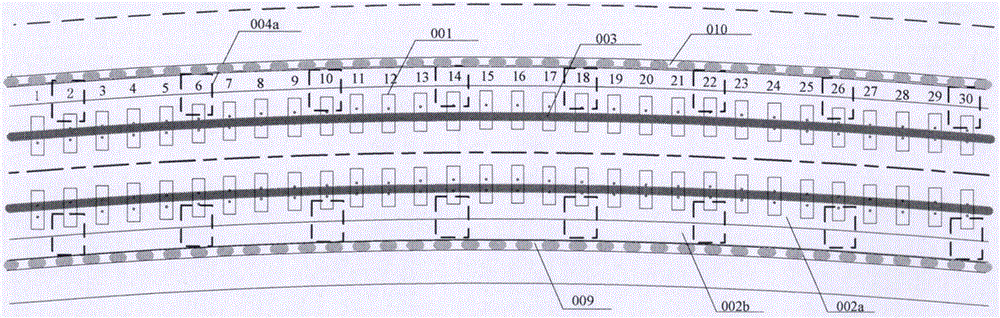

[0037] (2) Combined with the structural characteristics of the ballastless track, t...

Embodiment 2

[0045] The embodiment of the present invention provides a method for rectifying and repairing the centerline of the ballastless track without subsidence in the embankment section of the high-speed railway. Specifically, the ballastless track integral ballast bed (002a and 002b) and the superstructure are slightly raised by using a series of high-pressure airbag lifting devices , and then carry out the repair method of pushing and rectifying the line.

[0046] (1) Before lifting, use the total station and electronic level to measure the alignment of the ballastless track in a subgrade section, establish a measurement control network, and number each rail bearing platform, as shown in figure 1 with figure 2 As shown, according to the measurement results, combined with the deviation of the center line of the line, the design correction amount corresponding to the 1# to 30# rail bearing platform (001) in the line correction section is determined, see Table 2.

[0047] Table 2 De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com