Electrolytic Manganese Cathode Plate Draining Method

A cathode plate and electrolytic manganese technology, which is applied in the field of electrolytic manganese, can solve the problem that the cathode plate cannot be inserted into the electrolytic tank when the cathode plate is empty, and achieve the effect of shortening the extraction period, reducing the number of repeated positioning, and reducing the number of moves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

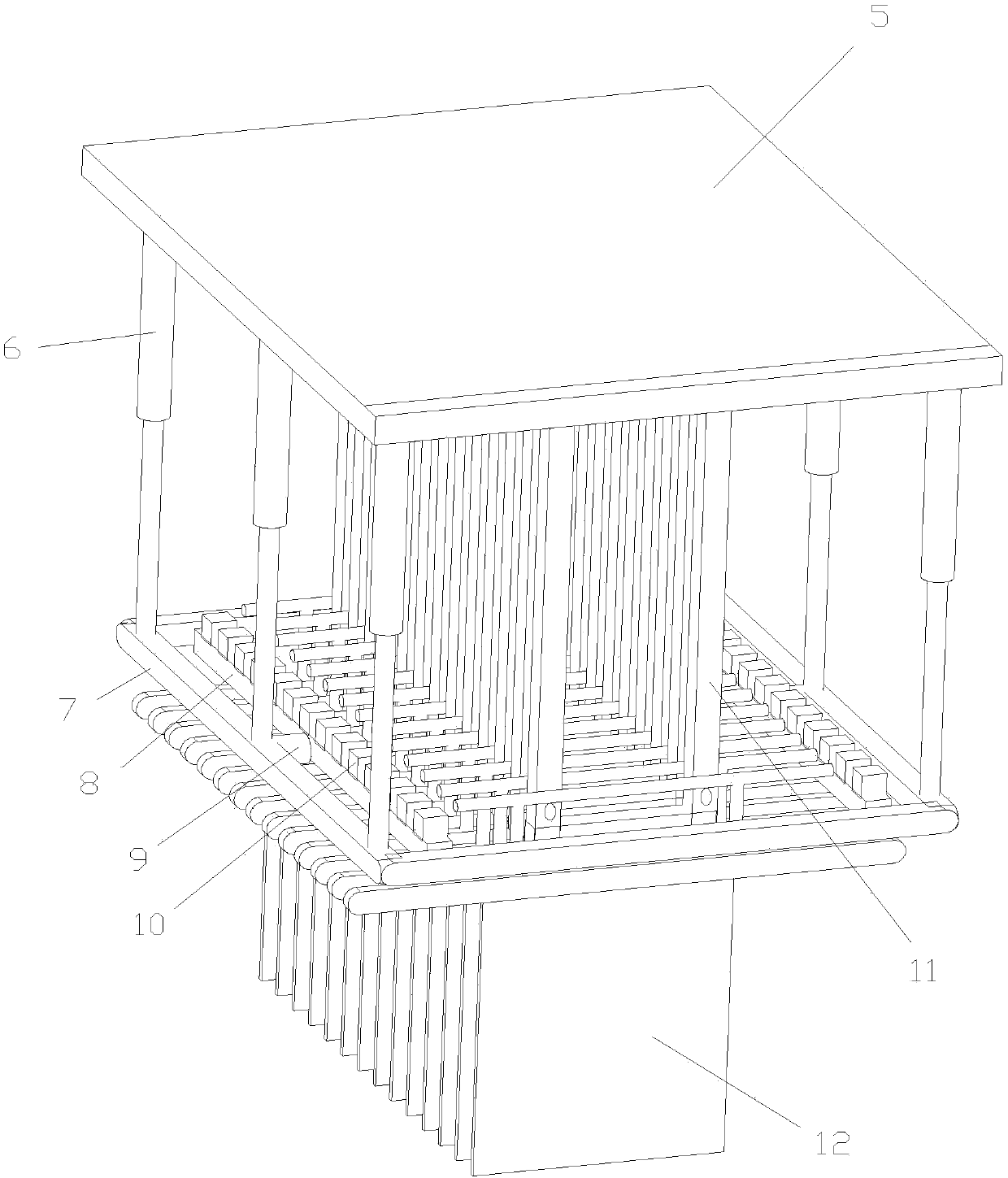

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] The extraction method of the electrolytic manganese cathode plate in this embodiment comprises the following steps:

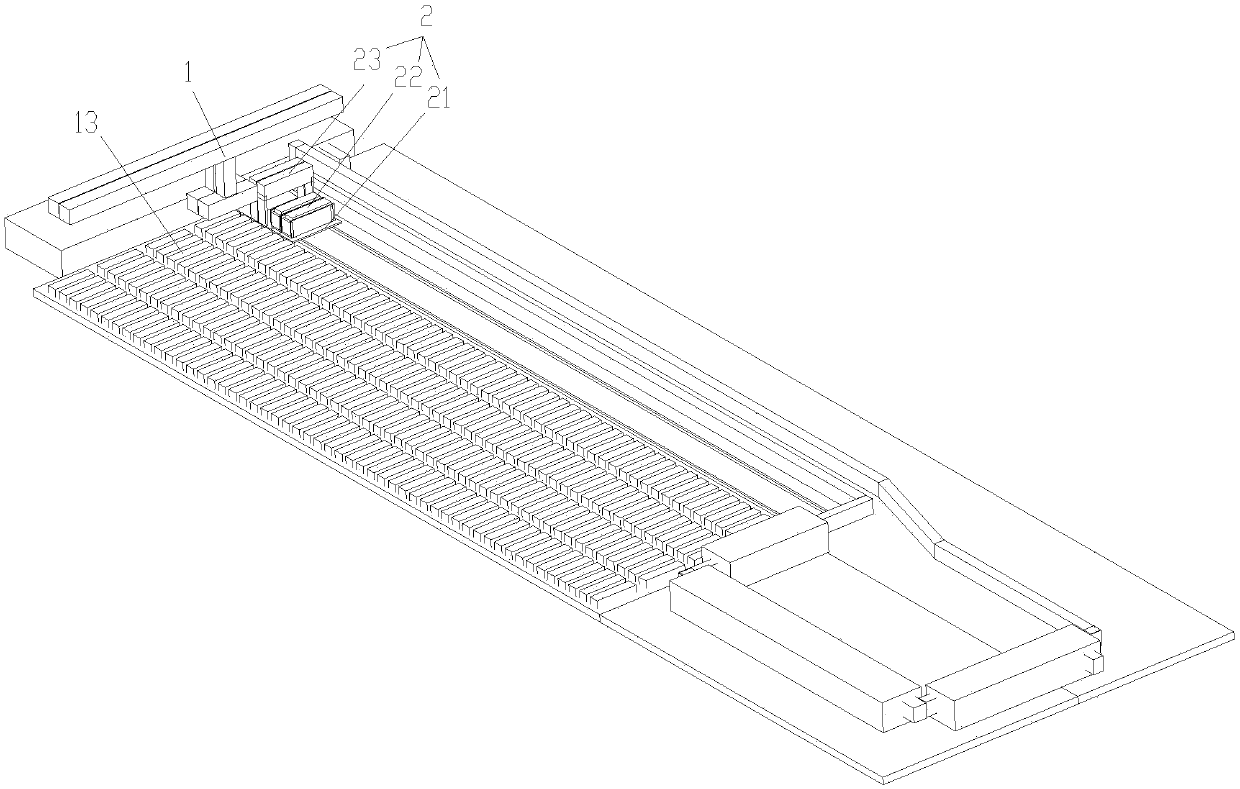

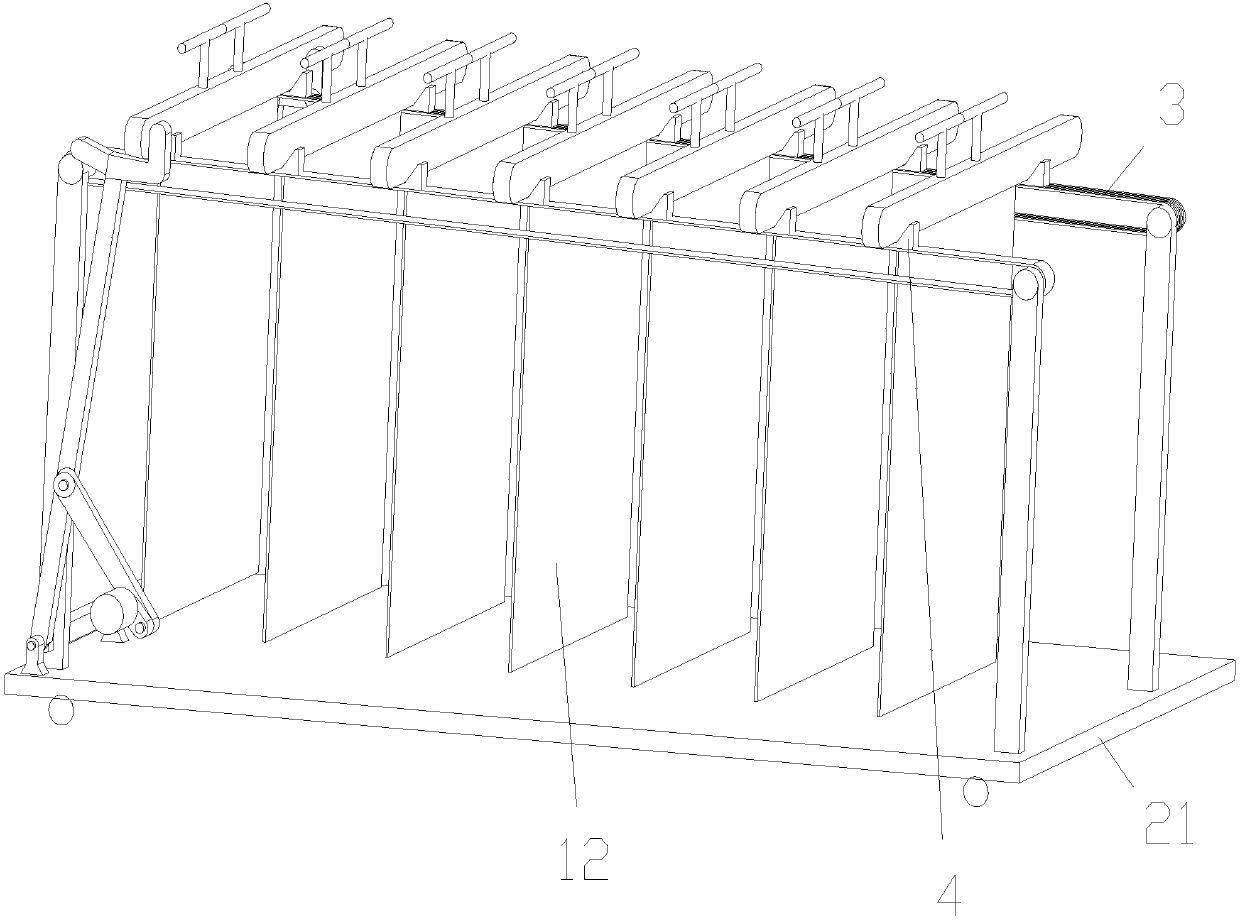

[0030] 1) Control the crossbeam of crane 1 to move along the guide rail, so that the crossbeam stops directly above the electrolytic cell to be treated, and at the same time control the movement of the cathode plate transfer conveying device 2 arranged next to the electrolyzer, so that the cathode plate transfer conveying device 2 The plate feeding adapter belt is located directly under the beam of the crane;

[0031] The cathode plate transfer and conveying device in this embodiment includes a rail car 21, a plate transfer transfer belt 22 arranged on the rail car, and a plate transfer transfer belt 23 arranged on the rail car , the transition belt for sending boards and the transition belt for board backup are both composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com