Preparation method of carboxymethyl chitosan

A technology for carboxymethyl chitosan and chitosan, which is applied in the field of preparation of carboxymethyl chitosan, can solve problems such as large consumption, and achieve the effects of low production cost, improved organic solvent and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

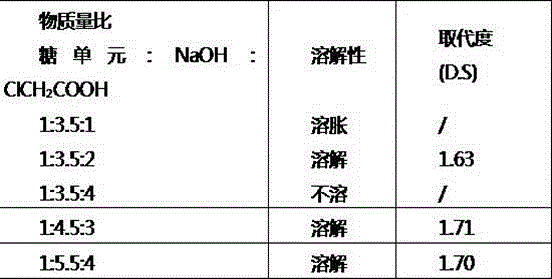

[0013] A preparation method of carboxymethyl chitosan, comprising the steps of: adding sodium hydroxide to chitosan and fully grinding it to make it uniformly mixed, dropping distilled water into it, mixing and grinding it uniformly for 2 hours, placing it for 12 hours for alkalization, and preparing the alkalized chitosan Add monochloroacetic acid to the sugar, grind and mix evenly, the mass ratio of chitosan, sodium hydroxide and monochloroacetic acid is: 1:3.5:3; add distilled water while grinding for 4 hours to obtain carboxymethyl The initial product of chitosan, the initial product of carboxymethyl chitosan was washed with 75% ethanol solution until the supernatant was free of Cl - , filtered by suction, and dried in an oven at 70°C to obtain carboxymethyl chitosan. The carboxylation degree of the obtained carboxymethyl chitosan reaches 1.65, and the viscosity of 1% carboxymethyl chitosan aqueous solution is 83mPa·s.

Embodiment 2

[0015] A preparation method of carboxymethyl chitosan, comprising the steps of: adding sodium hydroxide to chitosan and fully grinding it to make it uniformly mixed, dropping distilled water into it, mixing and grinding it uniformly for 3 hours, standing for 18 hours for alkalization, and preparing the alkalized chitosan Add monochloroacetic acid to the sugar, grind and mix evenly, the mass ratio of chitosan, sodium hydroxide and monochloroacetic acid is: 1:5.5:3; add distilled water while grinding for 6 hours to obtain carboxymethyl The initial product of chitosan, the initial product of carboxymethyl chitosan was washed with 75% ethanol solution until the supernatant was free of Cl - , filtered by suction, and dried in an oven at 60°C to obtain carboxymethyl chitosan. The carboxylation degree of the obtained carboxymethyl chitosan reached 1.68, and the viscosity of 1% carboxymethyl chitosan aqueous solution was 85mPa·s.

Embodiment 3

[0017] A preparation method of carboxymethyl chitosan, comprising the steps of: adding sodium hydroxide to chitosan and fully grinding it to make it evenly mixed, dropping in distilled water, mixing and grinding it evenly for 2.5 hours, placing it for 16 hours for alkalization, and adding to the alkalized shell Add monochloroacetic acid to the polysaccharide, grind and mix evenly, the mass ratio of chitosan, sodium hydroxide and monochloroacetic acid is: 1:4.5:3; grind for 5 hours while adding distilled water to obtain carboxymethyl Base chitosan initial product, wash carboxymethyl chitosan initial product with 75% ethanol solution until the supernatant is free of Cl - , filtered by suction, and dried in an oven at 60°C to obtain carboxymethyl chitosan. The carboxylation degree of the obtained carboxymethyl chitosan reaches 1.73, and the viscosity of 1% carboxymethyl chitosan aqueous solution is 89mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com