Novel intelligent electric flocculation treatment apparatus of power plant coal-containing wastewater

A technology of electrocoagulation and wastewater, which is applied in the direction of flocculation/sedimentation water/sewage treatment, natural water treatment, multi-stage water treatment, etc. It can solve the problems of electrode blockage, fast consumption of the electrode plate, and inability to operate, so as to avoid voltage Effects of rising, prolonging service life, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

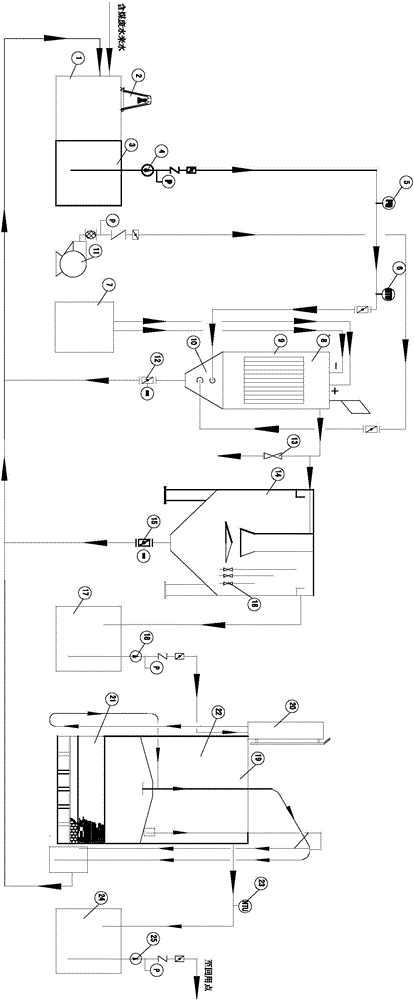

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

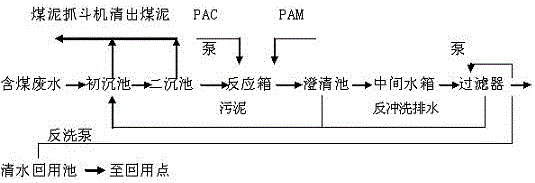

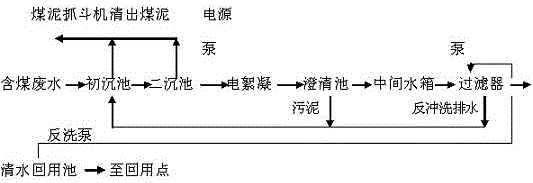

[0036] Such as figure 1 shown.

[0037]A new device for intelligent electrocoagulation treatment of coal-containing wastewater in a power plant, which includes a coal-water primary sedimentation tank 1, a secondary sedimentation tank 3, a high-frequency pulse power supply 7, a vertical electrocoagulation box 8, a micro-aeration fan 11, a clarifier 14, Intermediate water tank 17, valveless filter 19, high level water tank 20 and clear water pool 24 etc., as figure 1 As shown, a coal slime grab machine 2 is installed on the surface of the coal water primary sedimentation tank 1 and the secondary sedimentation tank 3, and the secondary sedimentation tank 3 is equipped with a lift pump 4 and is equipped with a flow meter 5 and an online turbidity meter. The pipeline of 6 is connected to the middle part of the lower mud hopper 10 of the vertical electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com