Automatic feeding device for industrial production line and control method

An automatic feeding and production line technology, applied in conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of high implementation cost, poor stability, complexity, etc., and achieve a high degree of automation, good consistency, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

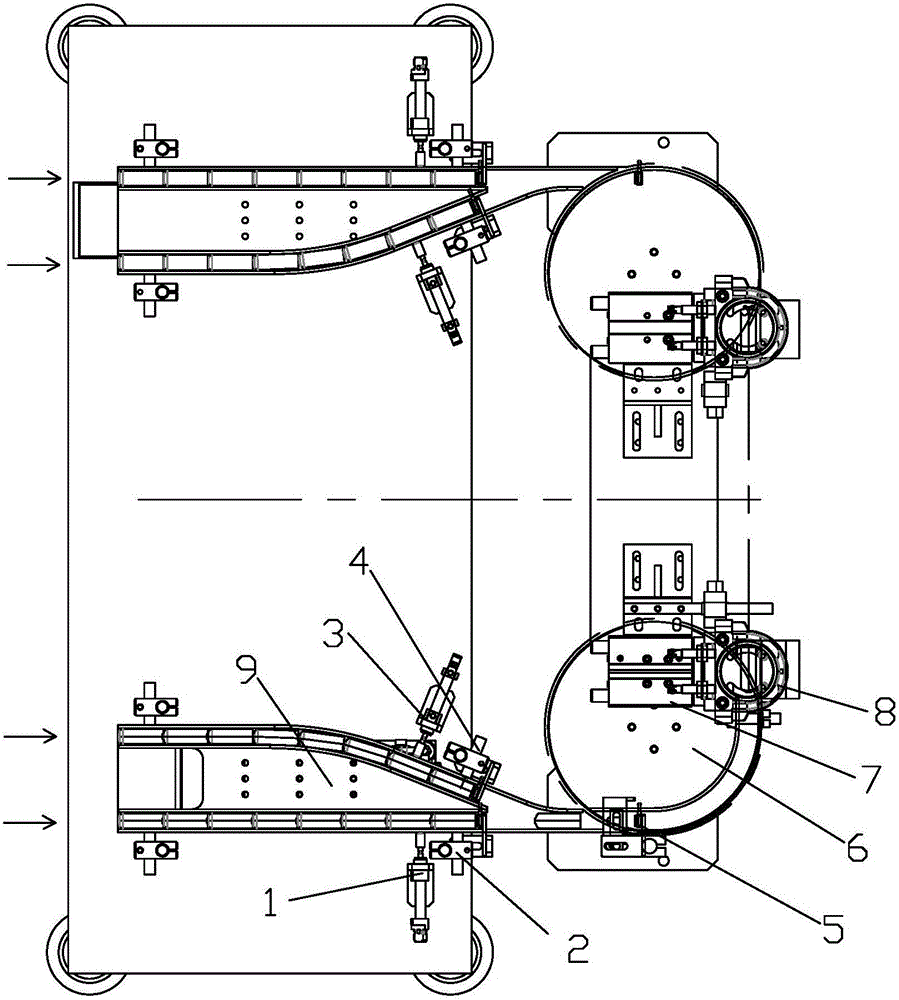

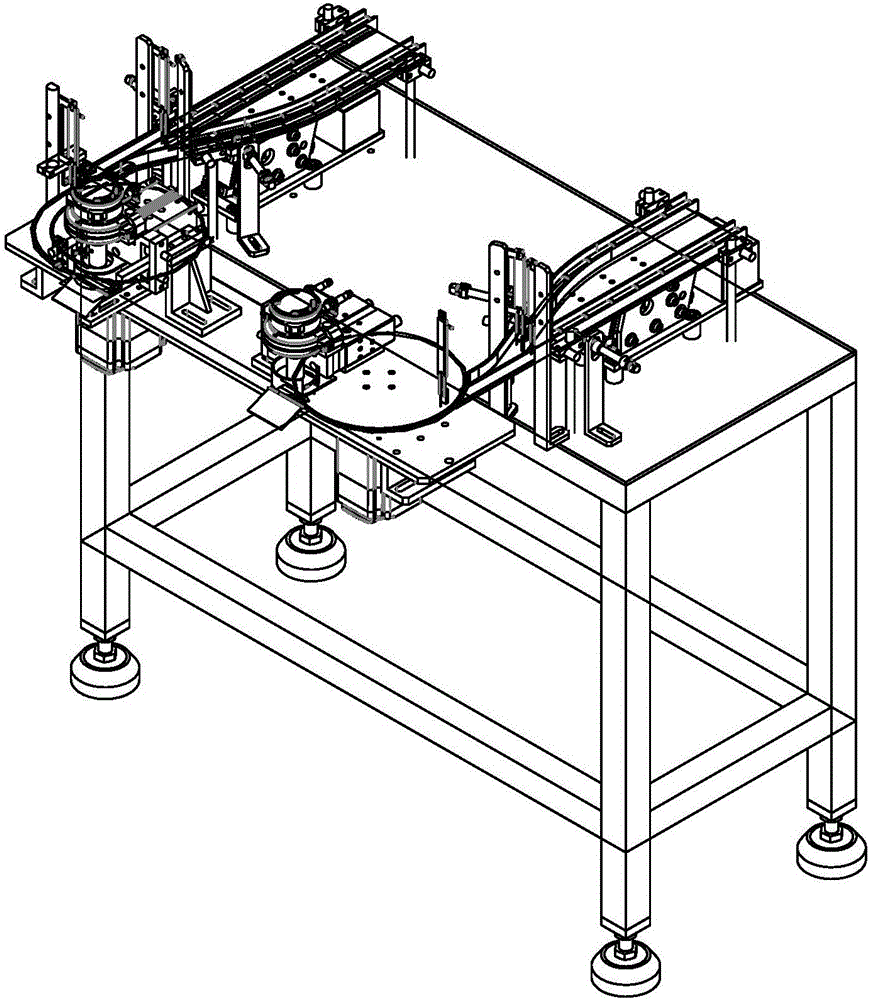

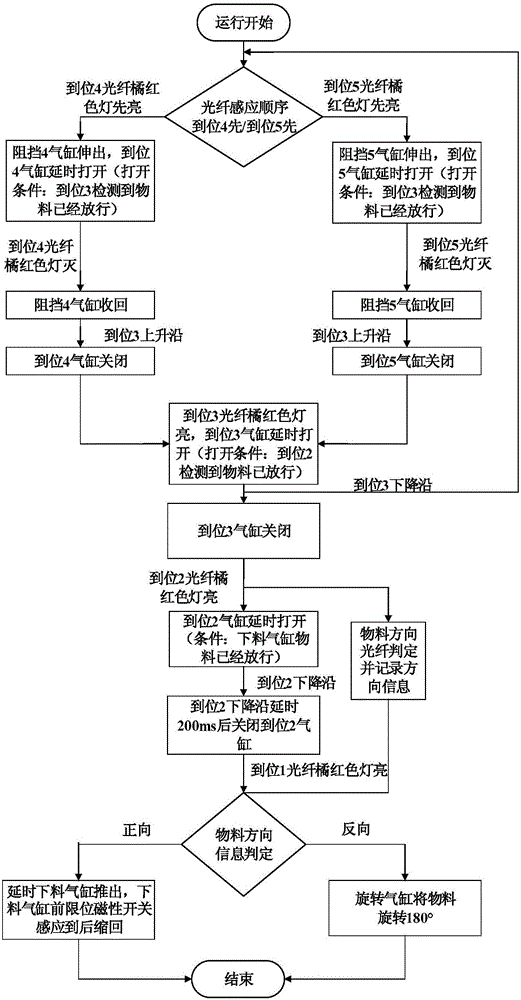

[0032] Embodiment 1: as Figure 1-3 , The feeding device is an automatic feeding device, which adopts the vibration feeding mode, and the vibrator can control the feeding speed. The material of the material machine enters the detection system continuously from the 4 feeding ports at the same time. The direct vibrating base conveys the incoming materials forward, and the four channels of incoming materials alternately and intermittently flow through the alternating cycle action of the four cylinders of the feeding cylinder A1, the blocking cylinder A2, the feeding cylinder B3, and the blocking cylinder B4. Front conveying, and the direction of the material is detected at the position of the blocking cylinder C5. The material is uniformly rotated 90° by the turntable 6 and then enters the rotary cylinder 8. After the direction of the material is automatically rotated to be consistent according to the material direction information, the material is pushed into the sprocket convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com