Solder paste printer and printing method thereof

A solder paste printing machine and solder paste technology, which is applied to printing machines, rotary printing machines, screen printing machines, etc. Replacement is complicated and other problems, to achieve the effect of reducing manual intervention, facilitating replacement, and improving production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

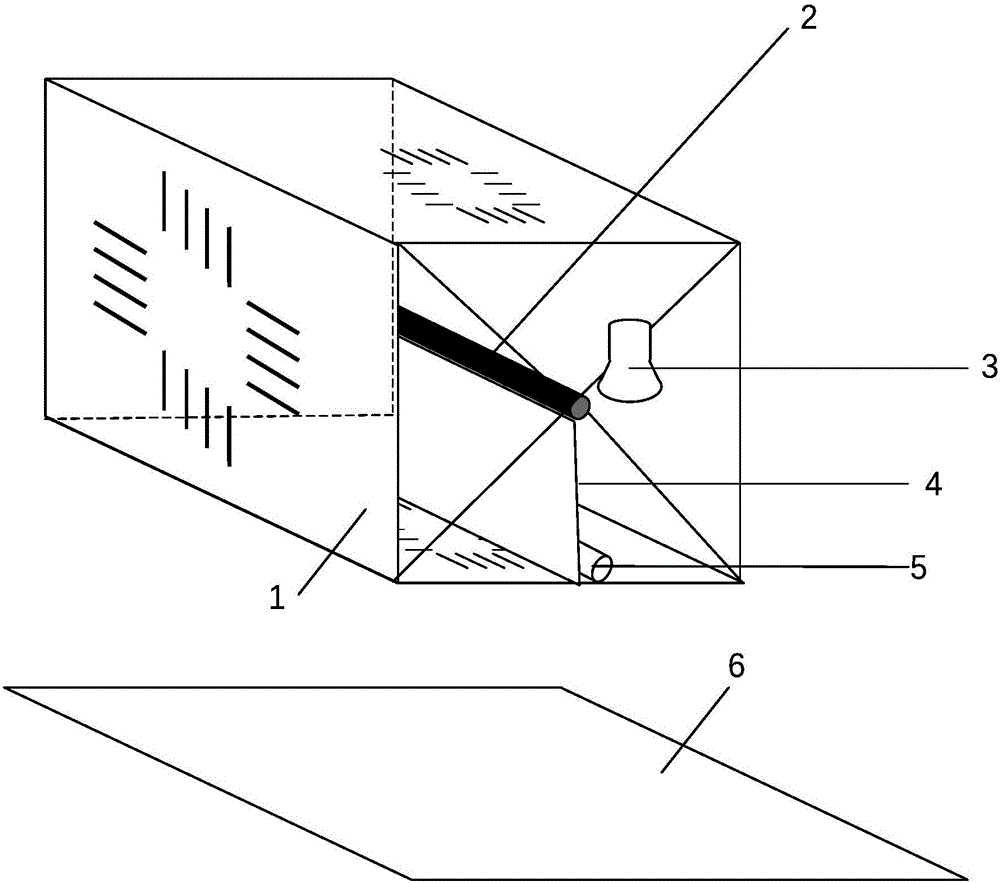

[0028] Please refer to figure 1 , Is a schematic diagram of the structure of the solder paste printer provided by the first embodiment of the present invention. The solder paste printer includes a screen group 1, a screen frame 2, a vision system 3, a solder paste scraper 4, a solder paste 5, and a printed circuit Board 6. Among them, the screen group 1 is fixed on the outer surface of the screen frame 2, the vision system 3 is fixed on the front end of the screen frame 2, and the solder paste scraper 4 and the solder paste 5 are located in the screen frame 2. Through the positioning of the working surface of the printed circuit board 6 by the vision system 3, the screen frame 2 drives the screen group 1, the solder paste scraper 4 and the solder paste 5 to the specified positions, and the solder paste scraper 4 passes the solder paste 5 through the screen group 1 is printed on the printed circuit board 6. After the printing is completed, the screen frame 2 is moved to the init...

Embodiment 2

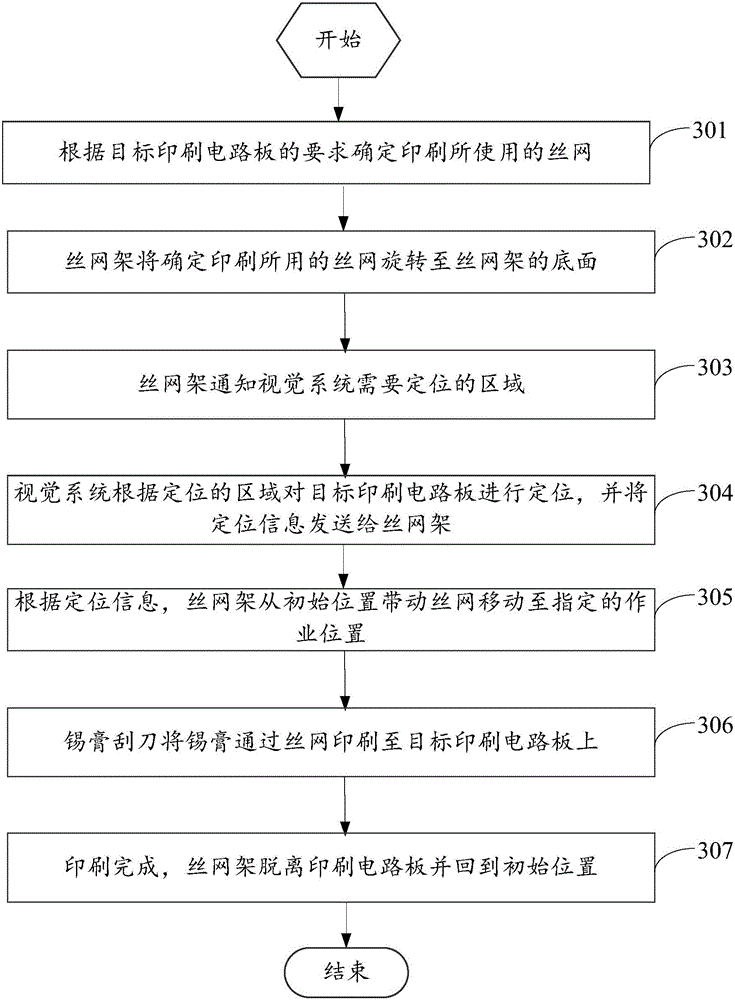

[0041] Please refer to image 3 The second embodiment of the present invention provides a solder paste printing method, which is implemented by the solder paste printer in the first embodiment, and the method includes the steps:

[0042] Step 301: Determine the screen used for printing according to the requirements of the target printed circuit board.

[0043] In step 302, the screen frame rotates the screen used for determining printing to the bottom surface of the screen frame.

[0044] Step 303: The screen frame informs the vision system of the area to be positioned.

[0045] Step 304: The vision system locates the target printed circuit board according to the location area, and sends the positioning information to the screen frame.

[0046] Step 305: According to the positioning information, the screen frame drives the screen from the initial position to move to the designated working position.

[0047] Step 306, the solder paste scraper screen prints the solder paste onto the target...

example 1

[0051] Example one is the case of partial solder paste printing on a large-size printed circuit board.

[0052] Please refer to Figure 4 , The printed circuit board 6 has a larger format and is divided into four areas for partial solder paste printing.

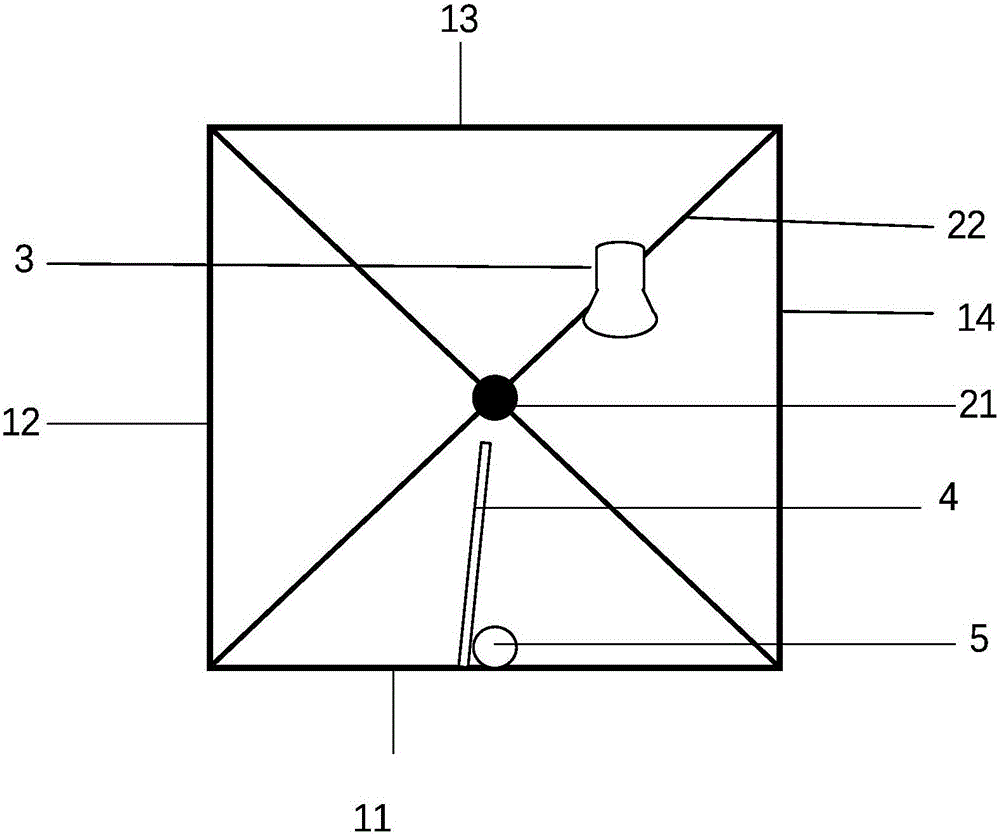

[0053] Specifically, the printed circuit board 6 is divided into areas 61, 62, 63, and 64 to be printed according to the requirements of the printing format, corresponding to the screens 11, 12, 13, 14 fixed on the screen frame 2 (such as figure 2 Shown).

[0054] The screen frame 2 is moved to the area to be printed 61, the screen 11 is determined to be used for printing, and the screen 11 is rotated to the bottom surface of the screen frame 2, and a signal is sent to notify the vision system 3 that the area to be positioned is the area 61.

[0055] The vision system 3 captures the image of the area 61 to be printed, locates the mark points, and transmits the positioning information to the controller of the screen frame 2.

[0056] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com