Base plate and edging detection method, alignment method and device thereof

A detection device and edge grinding technology, which is applied to measuring devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of difficult detection of edge grinding effects, and achieve the effect of low cost and simple implementation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

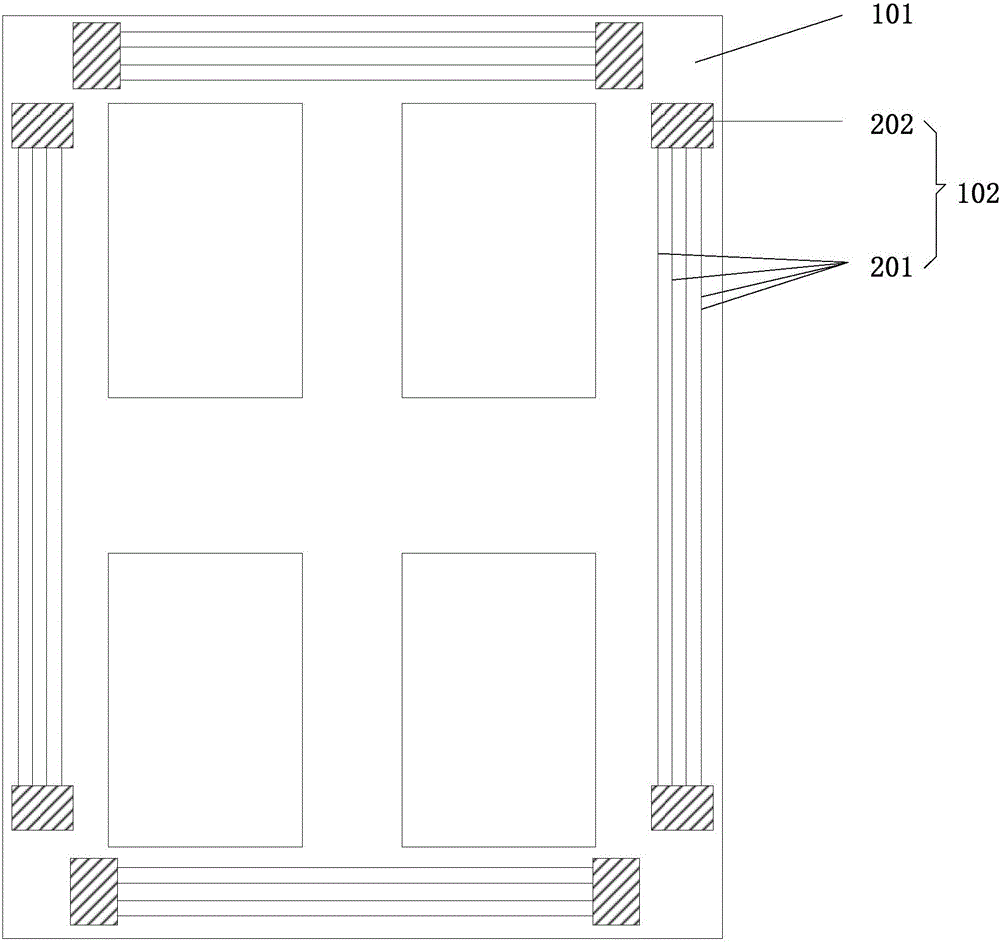

[0058] Please refer to figure 1 , figure 1 It is a schematic structural diagram of the substrate according to Embodiment 1 of the present invention, and the substrate includes: a base substrate 101 and four edge-grinding detection patterns 102 arranged on the base substrate 101, and the four edge-grinding detection patterns 102 are respectively Set on the four edges of the base substrate 101, the edge grinding detection pattern 102 is made of conductive material.

[0059] In the embodiment of the present invention, each of the edge grinding detection patterns 102 includes a plurality of resistance lines 201 arranged side by side, and the extension direction of the resistance lines 201 is the same as the extension direction of the edge of the base substrate 101 on which the resistance lines 201 are located.

[0060]Preferably, the multiple resistance lines 201 have the same width. Further preferably, the intervals between adjacent resistance lines 201 are the same.

[0061] ...

Embodiment 2

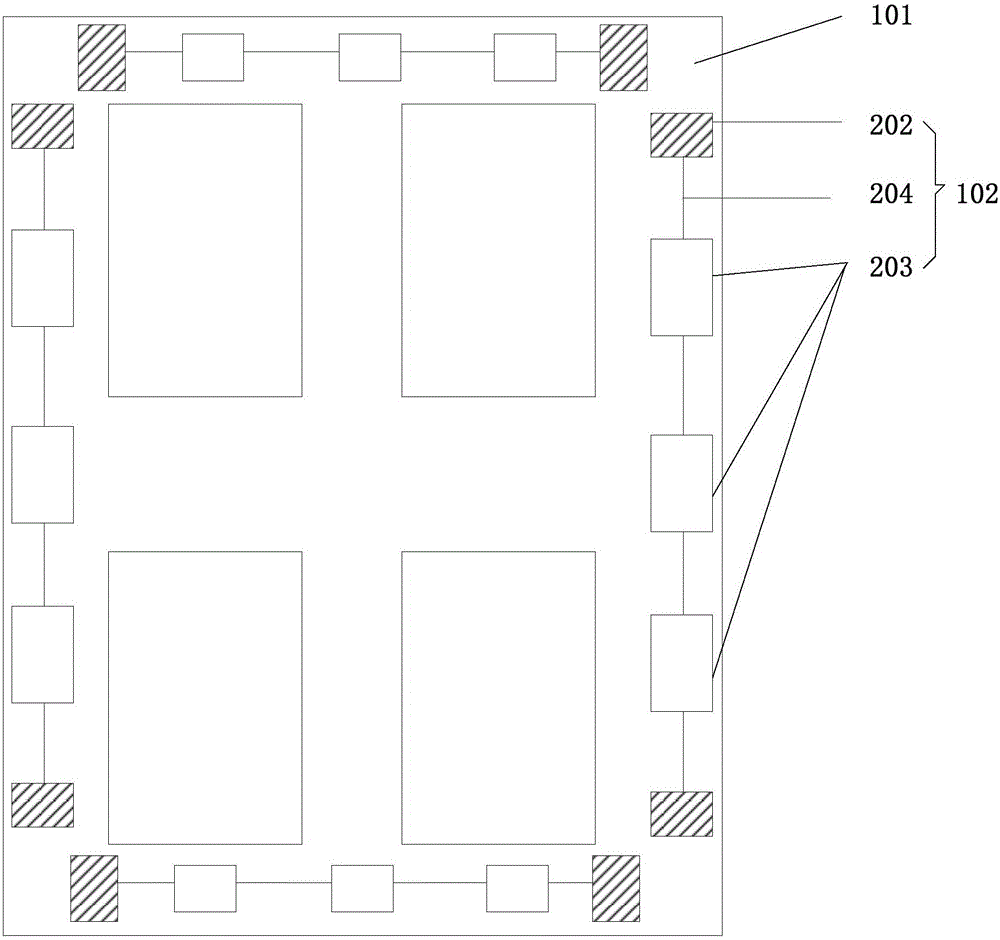

[0070] Please refer to figure 2 , figure 2 It is a schematic structural diagram of the substrate according to Embodiment 2 of the present invention, and the substrate includes: a base substrate 101 and four edge-grinding detection patterns 102 arranged on the base substrate 101, and the four edge-grinding detection patterns 102 are respectively Set on the four edges of the base substrate 101, the edge grinding detection pattern 102 is made of conductive material.

[0071] In the embodiment of the present invention, each of the edge grinding detection patterns 102 includes a plurality of resistance blocks 203 and a plurality of connecting wires 204 for connecting the plurality of resistance blocks 203 in series.

[0072] Preferably, the multiple resistor blocks 203 have the same size, and the multiple resistor blocks 203 are aligned along the extending direction of the edge of the base substrate 101 where they are located.

[0073] After the substrate of the embodiment of t...

Embodiment 3

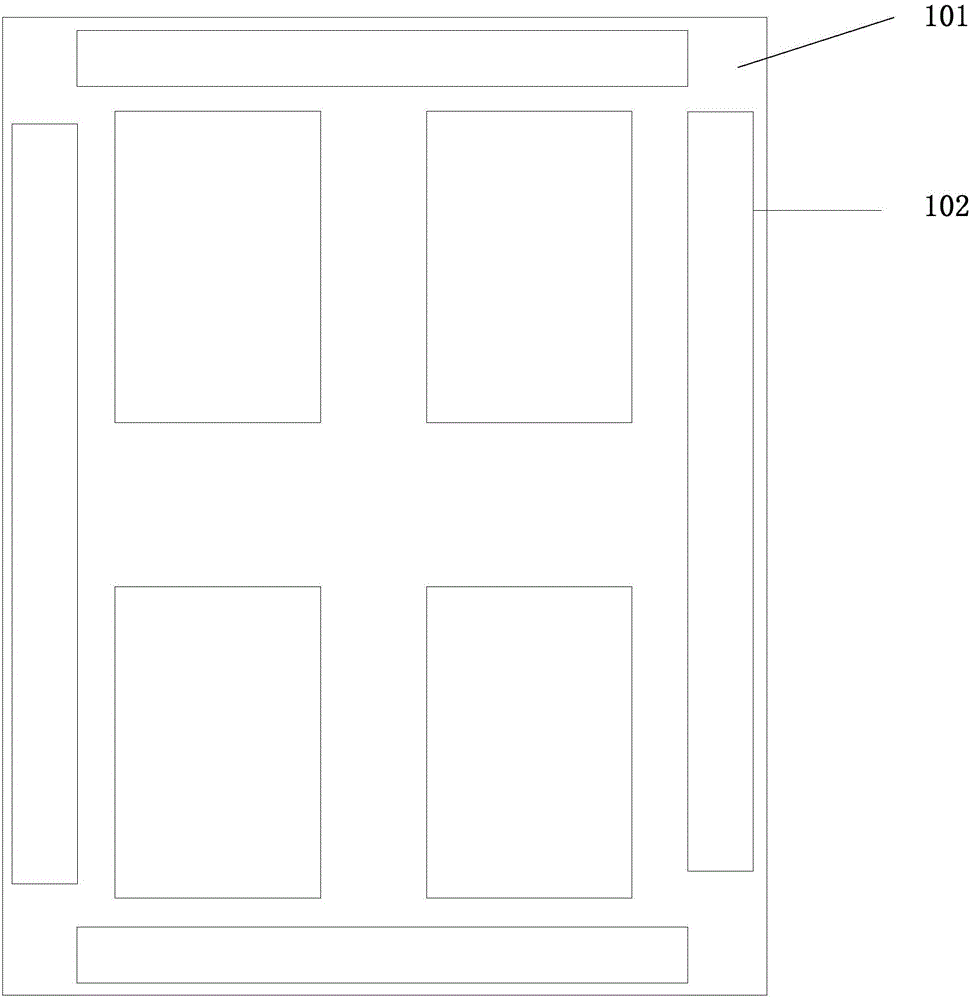

[0080] Please refer to image 3 , image 3 It is a schematic structural diagram of the substrate according to Embodiment 3 of the present invention, and the substrate includes: a base substrate 101 and four edge-grinding detection patterns 102 arranged on the base substrate 101, and the four edge-grinding detection patterns 102 are respectively Set on the four edges of the base substrate 101, the edge grinding detection pattern 102 is made of conductive material. In the embodiment of the present invention, the edge grinding detection pattern 102 is a strip-shaped conductive pattern, and the extending direction of the long side of the strip-shaped conductive pattern is the same as the extending direction of the edge of the substrate on which it is located.

[0081] After the substrate of the embodiment of the present invention is edged, since the edge grinding detection pattern 102 is close to the edge of the substrate, each strip-shaped edge grinding detection pattern 102 may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com