Graded crushing device for large particles

A classification device, large particle technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of shutdown and maintenance, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

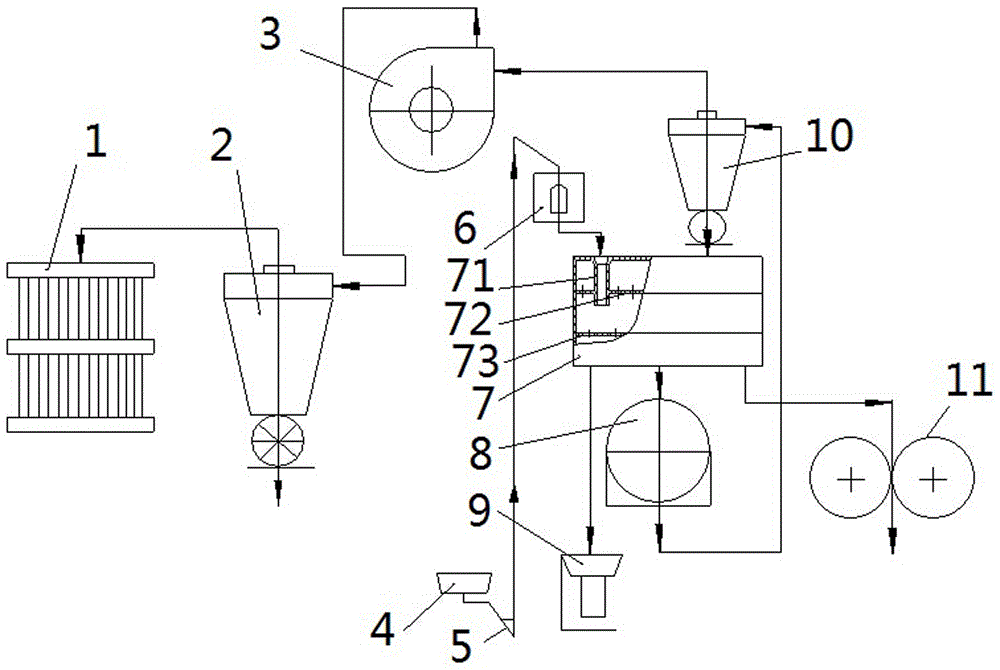

[0017] Such as figure 1 As shown, a kind of large particle crushing and grading device of the present invention comprises a plane rotary screen 7, and the plane rotary screen 7 comprises a first layer of screen surface 72 positioned at the top and a second layer of screen surface 73 positioned at the bottom, and the plane rotary screen 7 The end of the feeding port 71 is located between the first sieve surface 72 and the second sieve surface 73 , and the aperture of the first sieve surface 72 is smaller than the aperture of the second sieve surface 73 . The first outlet of the plane rotary screen 7 is connected with a primary crushing mechanism, the second outlet of the plane rotary screen 7 is connected with a secondary crushing mechanism, and the third outlet of the plane rotary screen 7 is connected with a scrap packing machine 9 .

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com