Working method of pressing-type soil block crusher with multilevel screening function

A working method and extrusion technology, applied in clod crushers, agricultural machinery and implements, applications, etc., can solve the problems of high labor intensity, low work efficiency, poor versatility, etc., and achieve low labor intensity, The effect of high work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through specific embodiments:

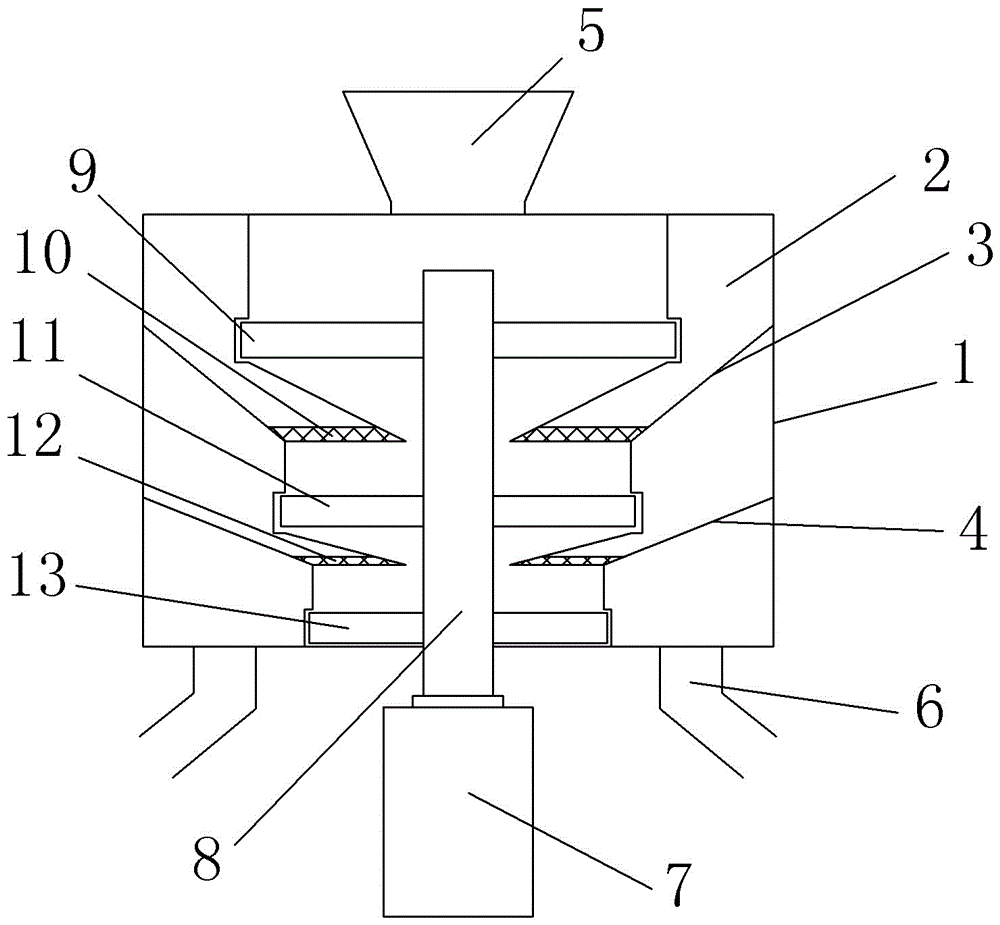

[0024] The reference signs in the drawings of the specification include: housing 1, screening chamber 2, first baffle 3, second baffle 4, feed hopper 5, discharge hopper 6, motor 7, shaft extension 8, first The crushing disk 9, the first elastic pad 10, the second crushing disk 11, the second elastic pad 12, and the third crushing disk 13.

[0025] The embodiment is basically as attached figure 1 Shown: The squeezing soil crusher with multi-stage screening function includes a casing 1. A feed opening is provided on the upper side of the casing 1, and a feed hopper 5 is provided at the feed opening. 5 includes a tapered section and a cylindrical section. The cylindrical section of the feed hopper 5 is at the bottom and is connected to the inlet. A working chamber is opened in the middle of the casing 1, and the walls of the working chamber are successively from top to bottom. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com