Tensioning device for a stirred ball mill with a belt or chain drive, and stirred ball mill

A technology of agitating ball milling and tensioning device, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

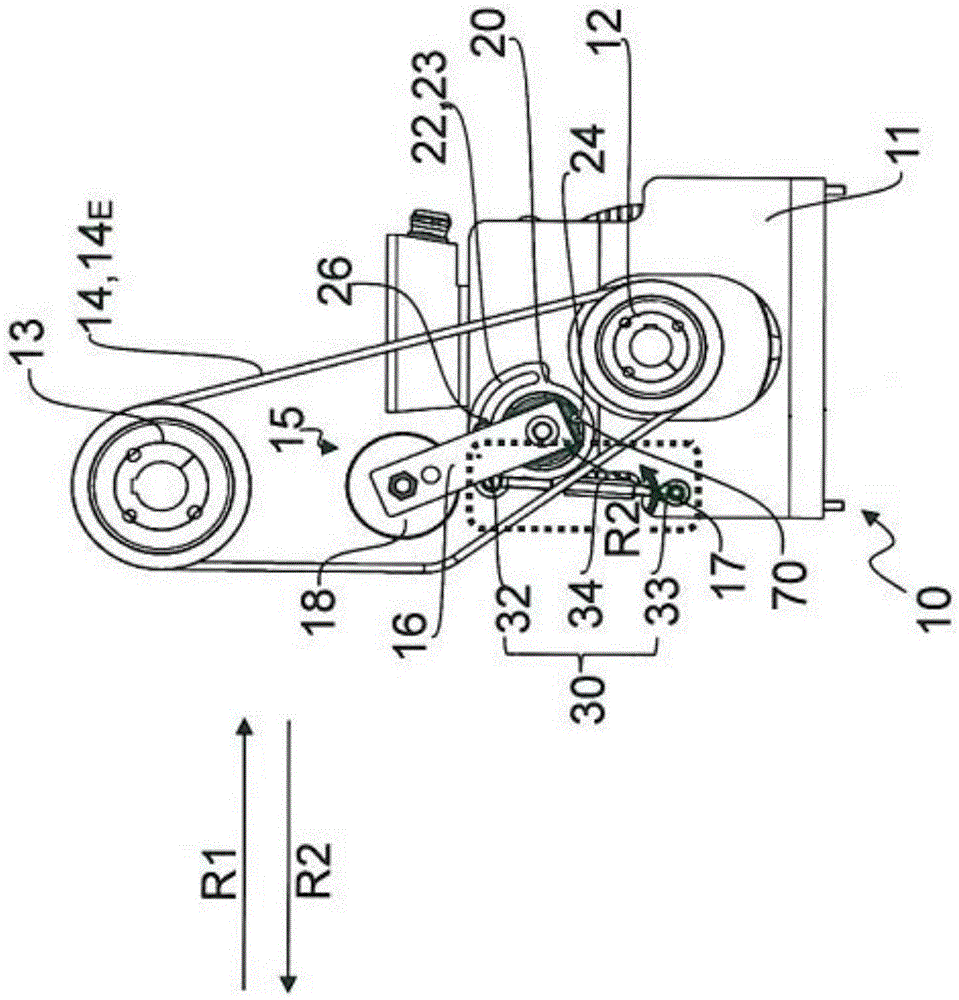

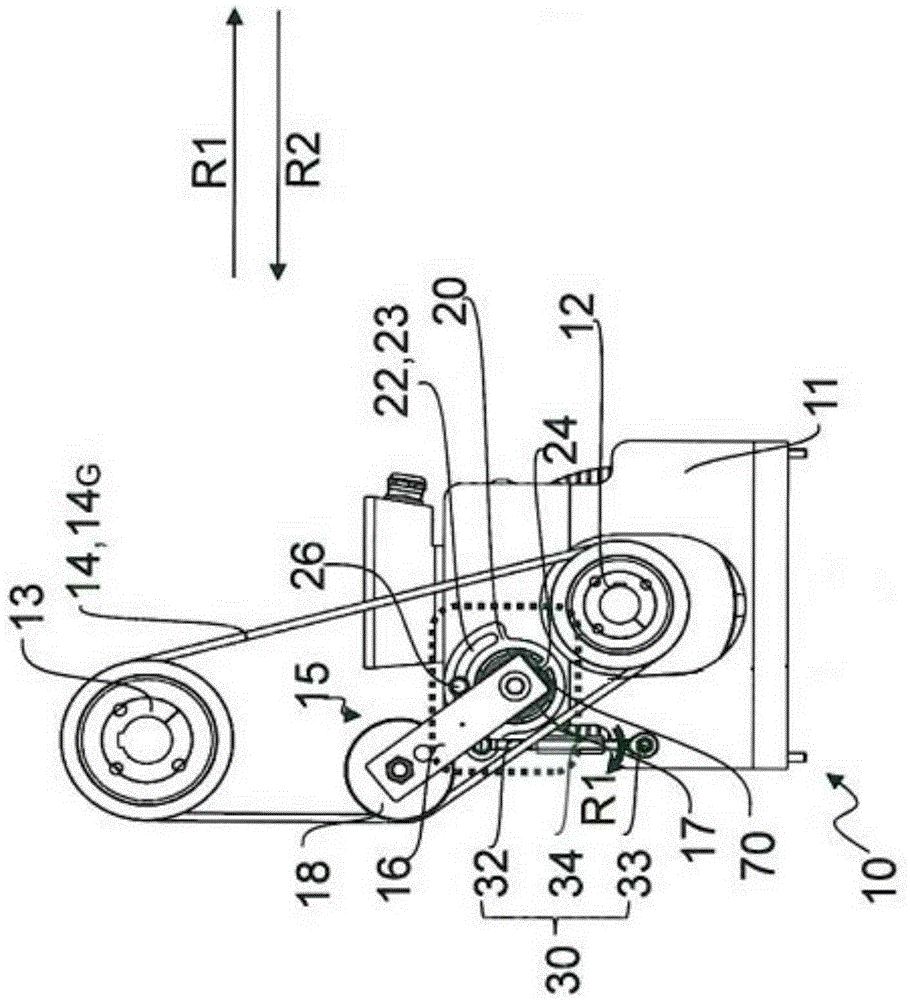

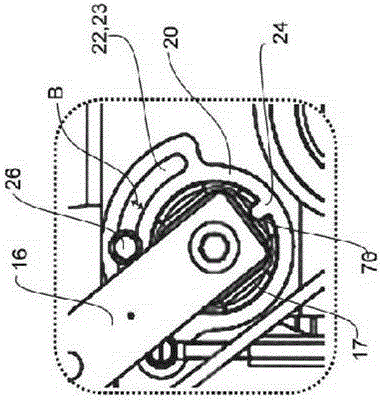

[0035] figure 1 A first embodiment of an agitator ball mill 1 a with a tensioning device 5 a according to the known prior art is shown. The stirring shaft 3a of the stirring ball mill 1a is driven by the drive shaft 2a via a chain or a belt 4a. A tensioning device 5 a is provided for adjusting the required belt tension of the belt 4 a. The tensioning device comprises a tensioning rod 6a with a tensioning wheel 8a arranged at a tensioning seat 7a. In order to adjust the tension of the belt 4a, the user must first loosen fastening means (not shown) at the tensioning seat 7a in order to be able to adjust the tensioning seat. The user must then place a tool on the clamping seat 7a and turn the clamping seat with the tool. The rotational movement is transmitted via the tensioning rod 6a to the tensioning pulley 8a, whereby the tensioning pulley presses on the belt 4a more or less depending on the direction of rotation. After the desired belt tension has been achieved, the faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com