Preparation method of polytetrafluoroethyl hollow fiber membrane assembly

A fiber membrane and hollow technology is applied in the field of preparation of polytetrafluoroethylene hollow fiber membrane modules, which can solve the problems of low industrialization of polytetrafluoroethylene hollow fiber membrane modules, achieve strong cost-effectiveness advantages, improve use effects, and control effects. more effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

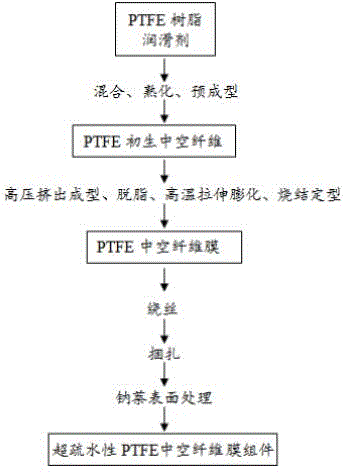

[0048] see figure 1 Shown, a kind of preparation method of superhydrophobic PTFE hollow fiber membrane module comprises the following steps:

[0049] Step 1) Preparation of PTFE nascent hollow fiber;

[0050] The ultra-high molecular weight dispersion polymerized PTFE resin is mixed with a lubricant, and after aging and preforming processes, the PTFE nascent hollow fiber is prepared; the outer diameter of the prepared PTFE nascent hollow fiber is 0.8mm~4.8mm, and the wall thickness 0.2mm~1.4mm;

[0051] Step 2) Preparation of PTFE hollow fiber membrane;

[0052] The PTFE nascent hollow fiber prepared in the previous step is extruded under high pressure, and after degreasing, high-temperature stretching and puffing, and sintering and setting processes, the PTFE hollow fiber membrane is prepared;

[0053] The conditions of the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com