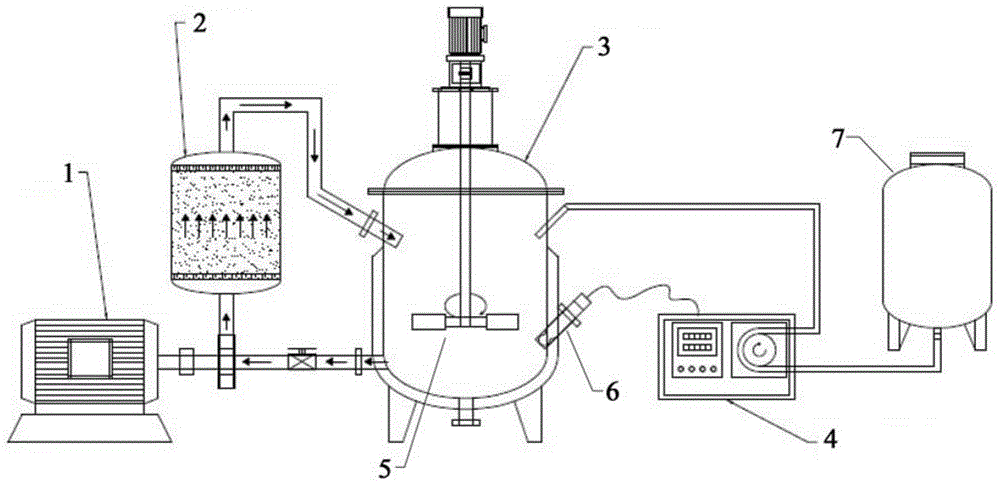

Immobilization reaction device and reaction method using immobilization technology

A reaction device and reaction technology, applied in the field of bioengineering, can solve the problems of not providing reaction devices and methods, and achieve the effect of improving contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1: the production of creatine phosphate

[0081] Design PCR primers according to the sequence of Chinese Patent Application Publication No. CN102808006, specifically:

[0082] Upstream primer CPK1:

[0083] 5'-GGGAATTCCATATGCCGTTCGGCAACACCCACAAC-3'

[0084] Downstream primer CPK2:

[0085] 5'-CCGCTCGAGCTTCTGCGCGGGGATCATGTCGTCG-3'

[0086] According to the method described in Chinese Patent Application Publication No. CN102808006, the creatine kinase gene was obtained and connected to pET-21a to obtain pET-21a(+)-CPK, which was transformed into Escherichia coli BL21(DE3).

[0087] Inoculate above-mentioned bacterial strain in 4ml LB medium (containing 100ug / ml ampicillin), cultivate 16 hours as primary seed liquid, inoculate in 100ml LB medium (containing 100ug / ml ampicillin) by 1% quantity ratio after completion . The secondary seeds were cultivated at 37° C. and 200 rpm for 10 hours, and then 1% of the secondary seeds were inoculated into a 100 L fermen...

Embodiment 2

[0093] Example 2: Production of S-adenosylmethionine

[0094] Design PCR primers according to the sequence of Chinese patent CN101134948B, specifically:

[0095] Upstream primer parental S1:

[0096] 5'-AGCCTAGGTTAATTAACTTTAAGAAGGAGATACATATGAGAAACATAATTGTAAA-3'

[0097] Downstream primer parent S2:

[0098] 5'-ATAAGCTCAGCGGCGCGCCTTAGAATGTAGTTACTTTTTCCTTCA-3'

[0099] According to the Chinese patent CN101134948B, M.Jannaschii ATCC43067 (ATCC, USA) DNA was used as a substrate for PCR, and the PCR product was treated with restriction endonucleases PacI and AscI and ligated into pGEMT-EASY (Promega, USA) , to obtain pGEMT-SAM. The recombinant expression vector was transformed into Escherichia coli HB101 to obtain a strain expressing S-adenosylmethionine synthetase.

[0100] The bacterial strain containing pGEMT-SAM was inoculated in 5ml LB medium (containing 50mg / L ampicillin) and cultivated for 16 hours as the primary seed liquid, and was inoculated to 100ml LB medium (conta...

Embodiment 3

[0107] According to the preparation method of Example 1, the creatine kinase gene and E. coli cells expressing the gene were obtained, and fermentation was carried out to prepare creatine kinase immobilized E. coli cells on the carrier. The shape of the carrier was a strip: 22 cm long and 5 cm wide , Thickness 5mm, real weight 45.8g.

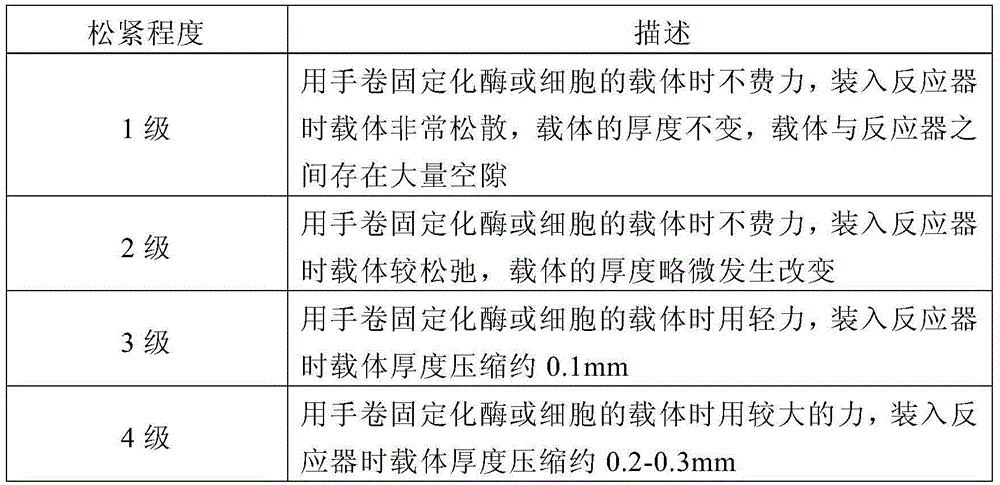

[0108] The above prepared carrier bearing immobilized E. coli cells with creatine kinase was installed in an immobilized enzyme / immobilized cell reactor. The reactor is a cylinder made of organic glass with a height of 1.8 cm and a radius of 9 cm. Use a knife to trim about 3 cm from the head and tail of the above-mentioned carrier with a slope of 45°, and roll it into a homogeneous cylinder with a height of 1.5 cm and a radius of 9 cm, weighing 30 g. The cylinder was inserted into the reactor so that it was tight enough to meet the Class 3 standard described in Table 1 and that there was no gap between the side wall and the inner wall of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com