Collating frame used for collating machine

A technology for collating machines and page racks, applied in the field of collating racks for collating machines, capable of solving problems such as uneven stacking of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

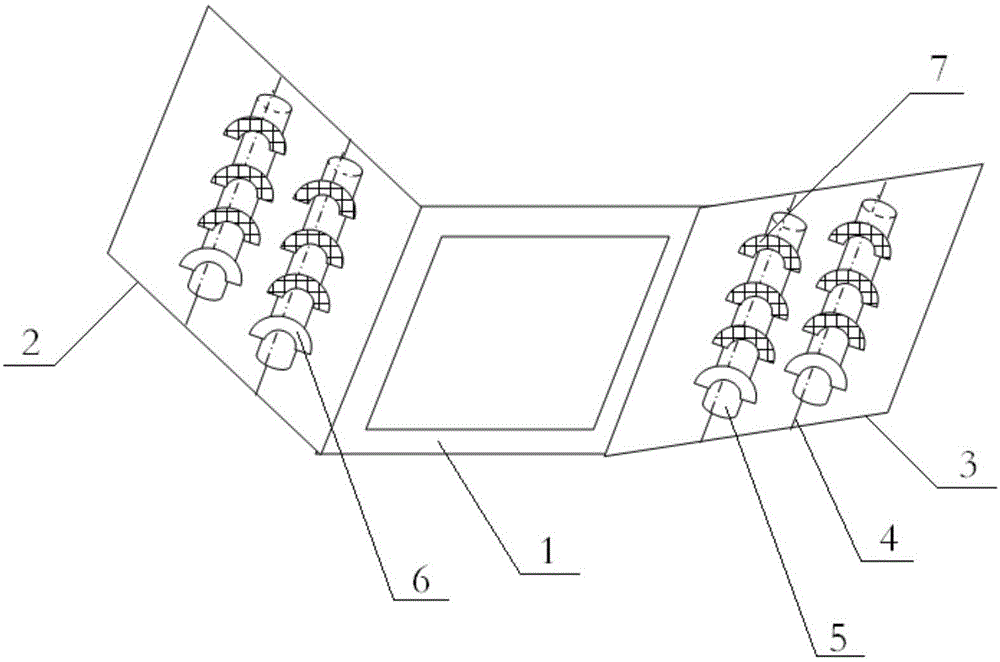

[0016] Such as figure 1 As shown, a collating rack for a collating machine is composed of a bottom bracket 1, a first bracket 2, a second bracket 3, a number of cross bars 4 and a rotating shaft 5, and the bottom bracket is a hollow back-shaped structure with four sides of equal length. , and the side lengths of the first bracket and the second bracket are equal to the side length of the bottom support, the first bracket and the cross bar are vertically fixed, the second bracket and the cross bar are vertically fixed, and the first The spacing between each of the crossbars fixed in the bracket / second bracket is the same, the shaft and the crossbar are vertically arranged, and the outer peripheral surface of the shaft is nested with a protruding piece 6 used to limit the paper. A contact sensor 7 is provided on the adjacent side of the paper. The contact sensor is connected to the controller circuit of the collating machine. During the working process, the paper is smoothly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com