Rubber fast cooling device

A rapid cooling and rubber technology, applied in the field of rubber equipment, can solve the problems of low production efficiency and easy blockage of cooling channels, and achieve the effect of improving production efficiency, saving equipment costs, and simplifying the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

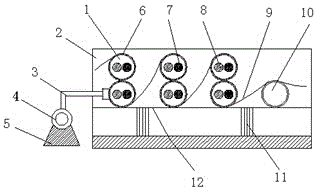

[0019] This embodiment includes: body 2 and a motor 4 positioned at one end of the body 2, the motor 4 is connected to the body 2 through a drive shaft 3, and a base 5 is provided at the bottom, the body 2 includes a traction roller 1, a conveyor belt 9, a support roller 10, a support The rod 11 and the connecting rod 12, the traction roller 1 is controlled and driven by the motor 4 through the transmission shaft 3, the conveyor belt 9 passes between each traction roller 1, and the support roller 10 is located on the right side of the traction roller 1 and is passed around by the conveyor belt 9, The upper and lower ends of the connecting rod 12 are respectively connected with the traction roller 1 and the supporting rod 11;

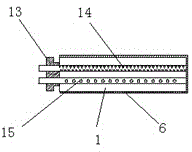

[0020] The traction roller 1 includes a stainless steel roller body 6, a cold air pipe 7, a cold water pipe 8 and a joint 13. The stainless steel roller body 6 is provided with a cold air pipe 7 and a cold water pipe 8. The joint 13 is connected to one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com