Photovoltaic assembly with built-in diodes

A technology with built-in diodes and photovoltaic modules, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve problems such as damaged components, difficult operation, and diode unit settings, so as to reduce the amount of potting glue and save copper sheets and wires The effect of box volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

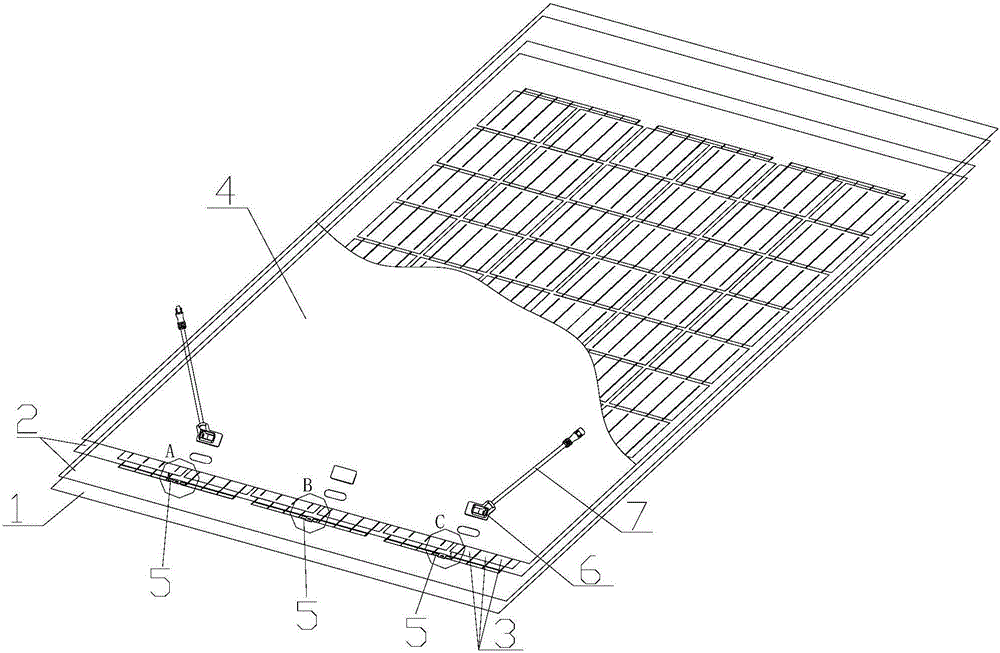

[0029] Embodiment 1, see Fig. 1-Fig. 4.

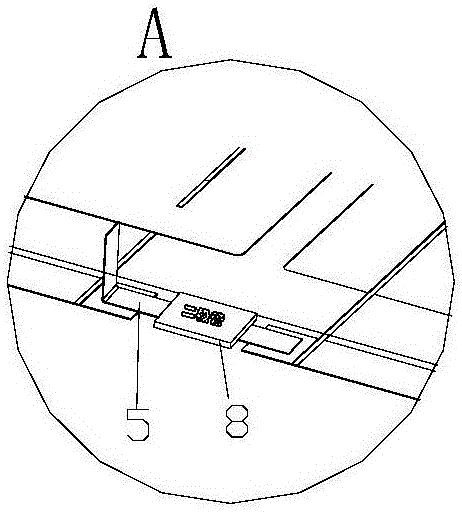

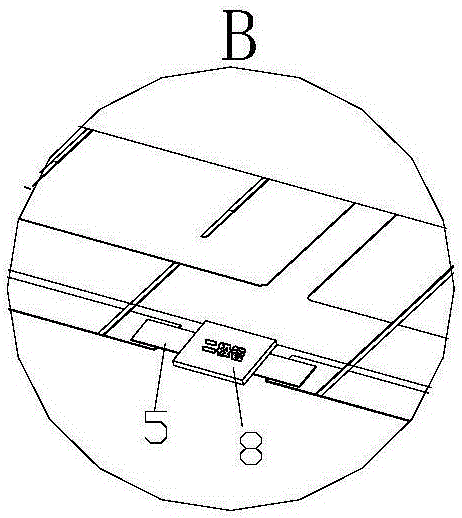

[0030] This embodiment provides a photovoltaic module with built-in diodes, such as Figure 1a-Figure 1d with figure 2 As shown, the photovoltaic module includes a front glass 1 , a front / rear encapsulation material layer 2 , battery strings 3 , bus bars 5 and a back plate or back glass 4 . A junction box 6 is arranged on the back plate or back glass 4 , and cables 7 and positive and negative terminals are connected to the junction box 6 . Such as image 3 As shown, a section of bus bar 5 is pre-welded on the positive and negative poles of the diode 8, and a longer bus bar is pre-welded if one of the poles needs to be connected to the wire box. When the components are stacked, the diode 8 with the bus bar 5 is connected according to the polarity between the two battery strings that need to be bypassed. One end of the longer bus bar 5 is pre-welded, and this part of the bus bar that grows is folded and led out of the assembly. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com