High-current USB Type C socket and manufacturing method thereof

A high-current, socket technology, applied in the direction of base/shell, contact parts, fixed/insulated contact members, etc., can solve the problems of difficult and large current passing, short-circuit of metal middle plate, etc., to enhance current passing and reduce impedance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

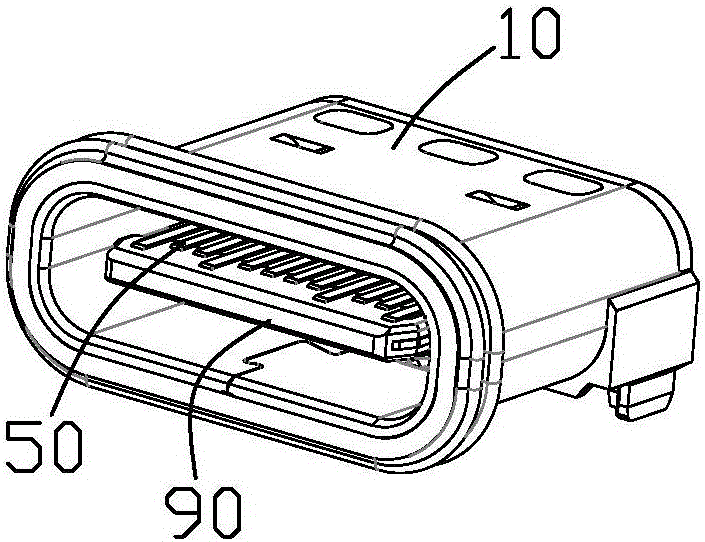

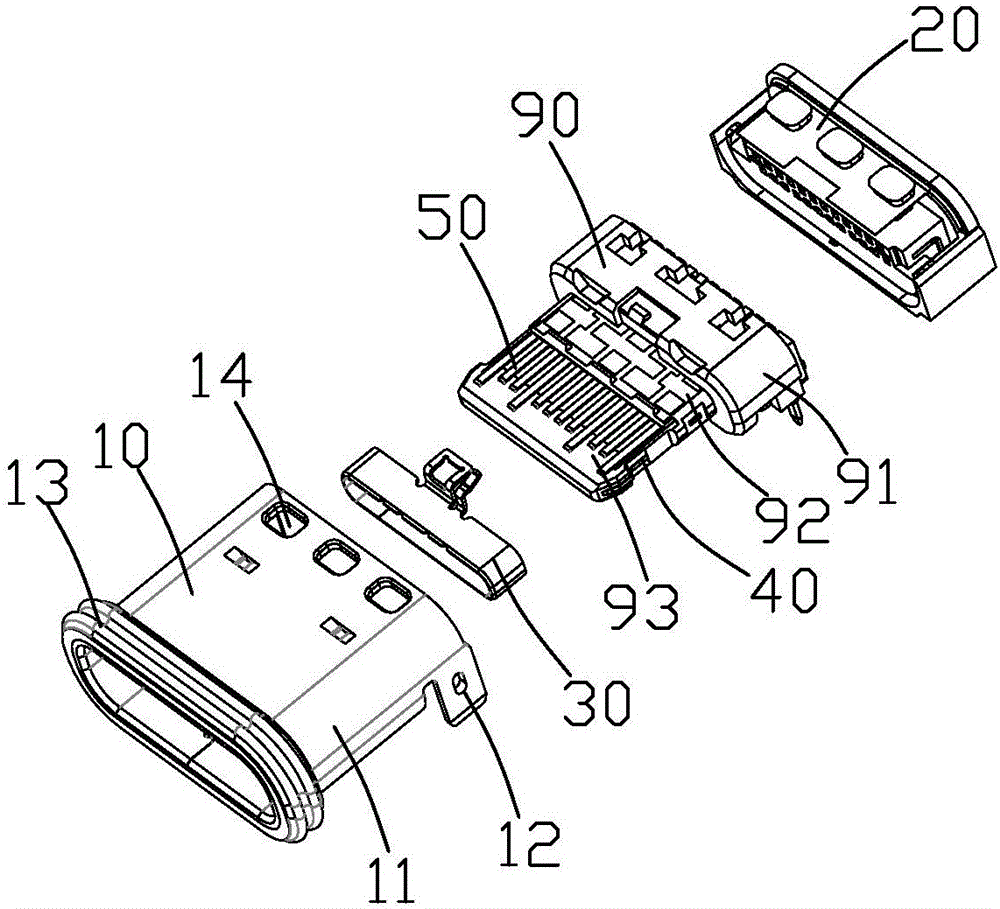

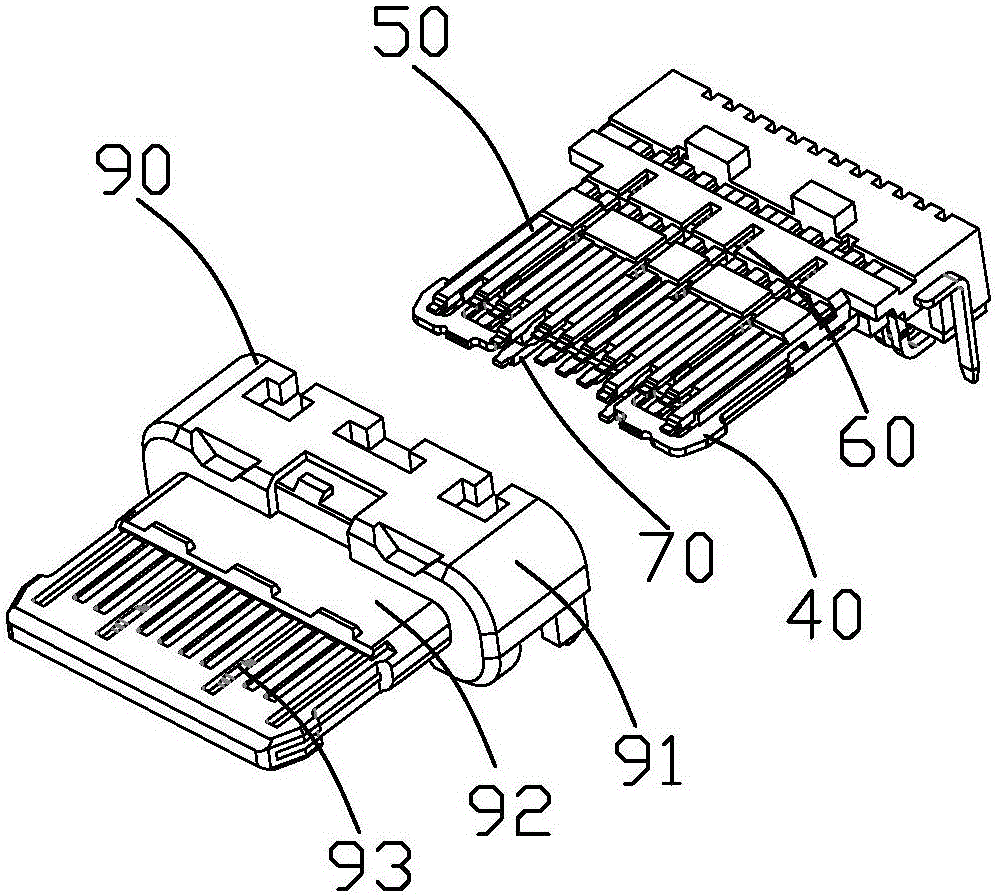

[0045] The following will combine Figure 1-Figure 15 The technical solution and technical principle of the first embodiment of this application are introduced in detail.

[0046] See Figure 1 to Figure 4 As shown, the high-current USB Type C socket of the present application includes a metal middle plate 40, a first terminal group 50 located on the upper and lower sides of the metal middle plate 40, a second terminal group 70, and the first terminal group 50 and The metal middle plate 40 is formed into an integrated first insulator 60, and a second insulator 80 formed on the second terminal set 70 (such as Picture 12 As shown), a third insulator 90 formed by forming the first insulator 60 and the second insulator 80 into a whole, a grounding member 30 sleeved on the third insulator 90, and surrounded by the third insulator The metal shell 10 outside the insulator 90 and the fourth insulator 20 integrally formed at the rear end of the metal shell 10 to eliminate the gap between ...

Embodiment 2

[0069] See Figure 16 , Figure 17 Compared with the first embodiment, the second embodiment shown in the second embodiment of the present application differs in that: the strip hole 42 on the metal middle plate 40 is penetrated in the insertion direction, so that the metal middle plate It is divided by 40 times into a completely independent middle main body 41b and two side main bodies 41a. At this time, the front ends of the first and second power terminals 50b, 70b do not need to be provided with a groove structure, and there is no risk that the first and second power terminals 50b, 70b are too close to the metal middle plate 40 .

[0070] But at this time, what needs to be changed is that during the forming process of the metal middle plate 40, the middle main body portion 41b and the two sides of the main body 41a are separately connected to the front strip of the metal middle plate 40. 48 can solve the problem of connecting the material belt caused by the separation of the...

Embodiment 3

[0072] See Figure 18 to Figure 20 Compared with the first embodiment, the third embodiment shown in the present application differs from the first embodiment in that the front end connecting portion 44 of the strip hole 42 of the metal middle plate 40 is cut off, and only the rear end connecting portion 43 is retained. The rear connecting portion 43 does not need to be thinned to form a recessed portion.

[0073] The first power terminal 50b is bent upward at the rear connecting portion 43 and then extends in parallel. The first power terminal 50b is located in front of the rear connecting portion 43 to form an upward fold. A bent portion 57 and a parallel extending portion 58 extending from the upward bent portion 57. The upward bending portion 57 and the parallel extending portion 58 are located on the holding portion 52. As a result, the distance between the parallel extending portion 58 and the rear connecting portion 43 will be increased, and the upper portion of the hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com