Sorting device and sorting method

A technology of crystal placement and work, applied in chemical instruments and methods, solid separation, classification, etc., can solve the problems of low picking efficiency and easy contamination of crystal grains, so as to reduce the probability of pollution, reduce time, and improve picking. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It can be seen from the background art that the prior art has the problems of low picking efficiency and easy contamination of the grains in the process of sorting the grains.

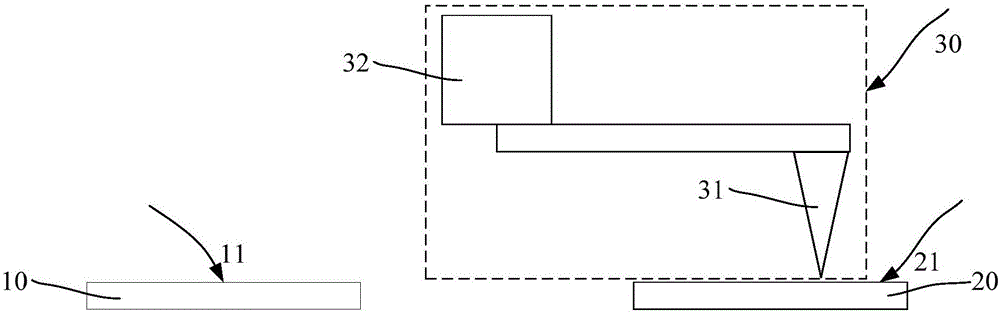

[0050] Now combined with a grain sorting method for analysis, refer to figure 1 , figure 1 It is a structural schematic diagram of a die picking device, and the die picking method includes: providing a chip tray 10 (chip tray), on the first carrying surface 11 of the chip tray 10, a plurality of dies 12 to be picked are placed Provide a silicon wafer frame 20 (wafer frame), the second carrying surface 21 of the wafer frame 20 is used to place the picked grain 12; provide a picking mechanism 30, the picking mechanism 30 includes a rotating part 32 and The rotating part 32 is connected to the picking part 31, and the rotating part 32 drives the picking part 31 to move between the first carrying surface 11 and the second carrying surface 21. The to-be-picked die 12 on the tray 10 is picked and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com