Work order identifying device

A technology for identifying devices and work orders, applied in the direction of collaborative devices, instruments, manufacturing computing systems, etc., can solve problems such as long production preparation time, and achieve the goal of reducing production time, reducing production preparation time, and reducing manual intervention steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

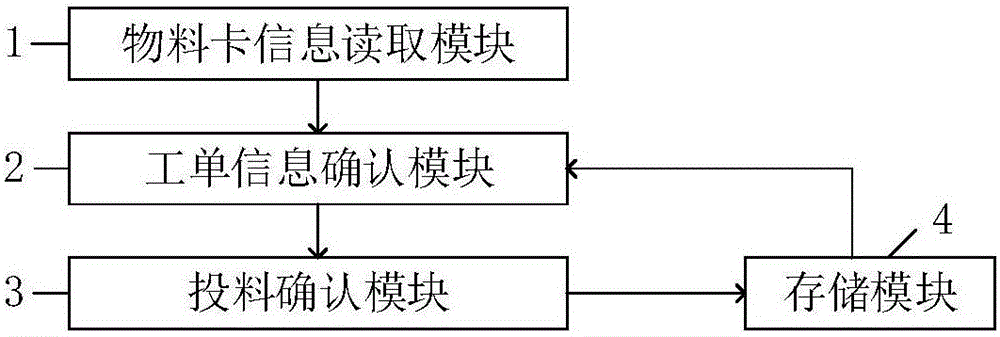

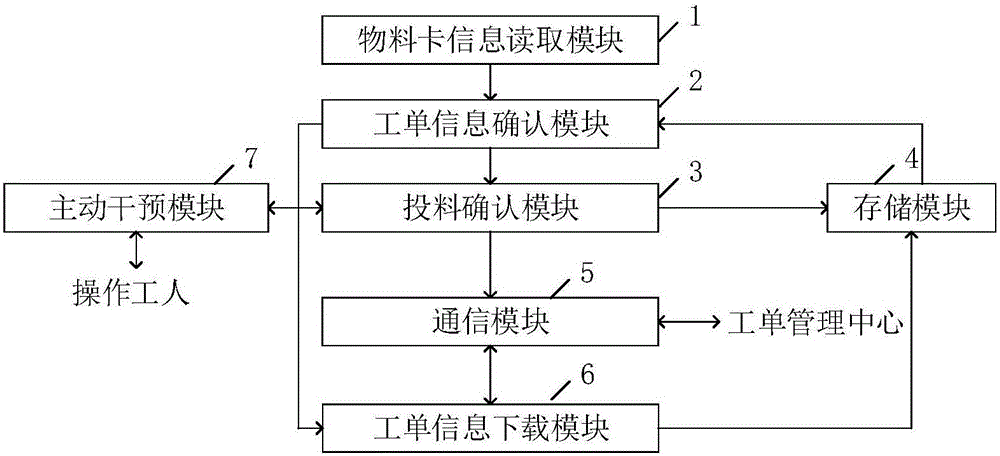

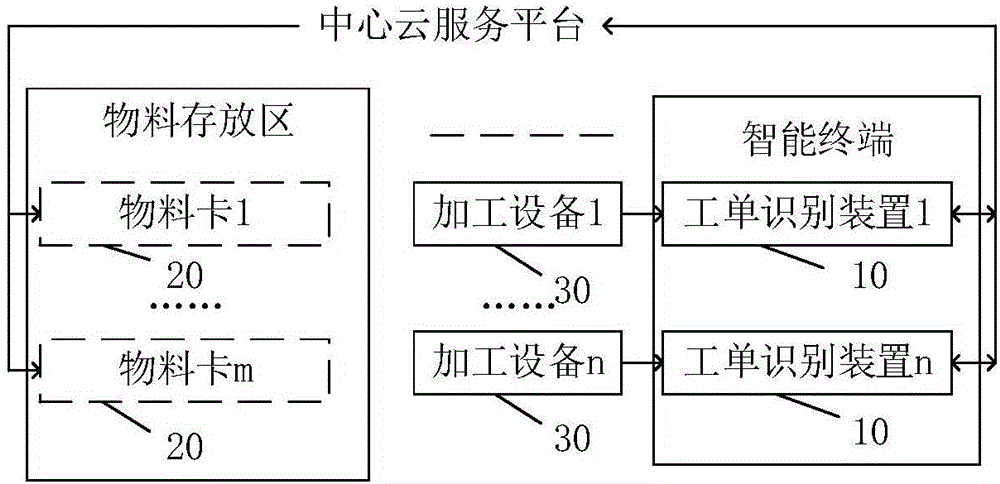

[0025] like figure 1 As shown, the work order identification device of this embodiment is set on the processing equipment and includes a material card information reading module 1, a work order information confirmation module 2, a feeding confirmation module 3 and a storage module 4; the material card information reading module 1 Connected with the work order information confirmation module 2, used to scan the material card within the preset distance, and read the work order information in the scanned material card, and send the work order information to the work order information confirmation Module 2; the work order information is written into the material card by the work order management center in advance; the material card is set on the material frame; the work order information includes the following items: material number, processing equipment type, processing Equipment number; the work order information confirmation module 2 is connected to the storage module 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com