A method for testing the crimping quality of fittings at the end of composite insulators

A technology for composite insulators and crimping quality, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of not being able to accurately detect the crimping quality of composite insulator end fittings, and achieve practicality Strong resistance, adjustable tensile load, sensitive detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

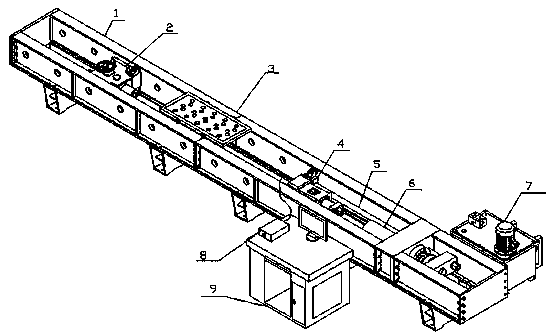

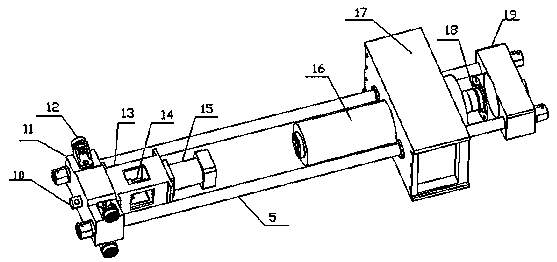

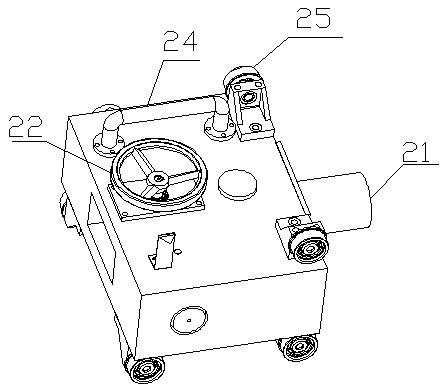

[0025] Such as Figure 1 to Figure 4 As shown, a system for detecting the quality of metal crimping at the end of a composite insulator according to the present invention includes a horizontal lathe 1 and a tie rod 5 arranged in the horizontal lathe 1. The axial setting of the type lathe 1, the tensile load device 6 and the torsional load device 4 are both sleeved on the two pull rods 5, in this embodiment, the tensile load device 6 is arranged on the right side of the torsional load device 4, and the The tensile load device 6 is used to provide tensile force for the composite insulator to be tested, and detect the deformation of the composite insulator to be tested under the condition of tensile force. The sample end of the torsional load device 4 is connected to one end of the composite insulator to be tested. The other end of the composite insulator to be tested is connected to the mobile locking device 2, and the torsional load device 4 is used to provide torsional force f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com