Lead screw guide rail reliability testing stand based on electro-hydraulic servo loading

An electro-hydraulic servo and reliability technology, which is applied in the direction of machine/structural component testing, electrical program control, measuring devices, etc., can solve the problems of few reliability loading tests, few reliability basic data of CNC grinding machine feed system, and inability to Accurately evaluate the reliability level of feed system of CNC grinding machine and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

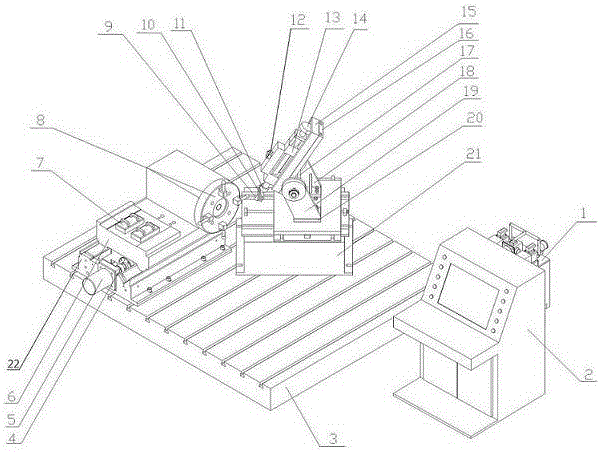

[0032] see Figure 1-3 , The invention discloses a screw guide rail reliability test bench based on electro-hydraulic servo loading, which includes a screw guide rail part, a load applying part and an automatic control part.

[0033] The guide rail part of the screw includes the upper and lower saddles and the screw nut pair. There are guide rails that cooperate with each other between the upper and lower saddles. Usually, the guide rails are V-flat with lubrication, good guiding performance, and high precision. Combined rails. The upper saddle 6 is provided with a weight 7 for simulating inertial load and a simulated grinding wheel force-bearing device 8, the simulated grinding wheel force-bearing device is fixedly connected with the upper slide saddle by bolts, and the simulated grinding wheel force-bearing device The force-bearing side of the disc is disc-shaped, and four force-bearing rods are evenly distributed on the outer end surface of the disc, and the end faces of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com