Gas nozzle and burner

A technology of gas nozzles and nozzles, which is applied in the field of cooking utensils, and can solve the problems of different atmospheric pressures, different requirements for nozzle apertures, and nozzles that cannot change apertures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

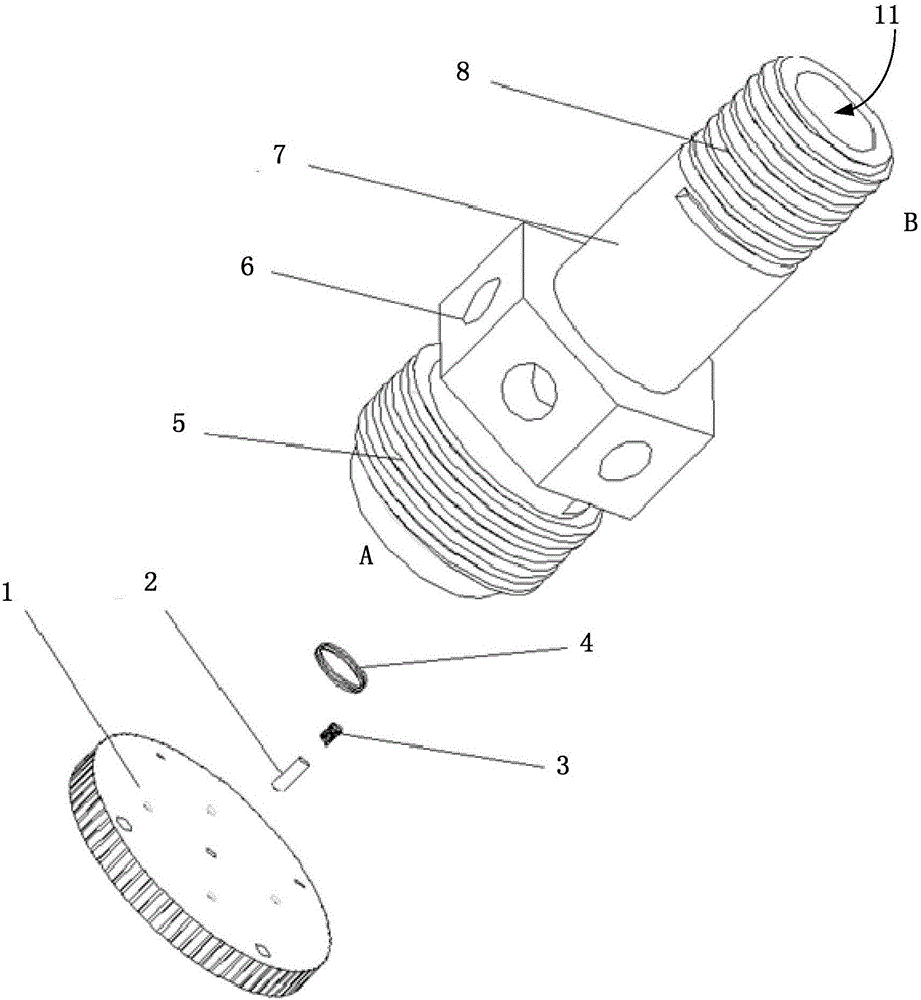

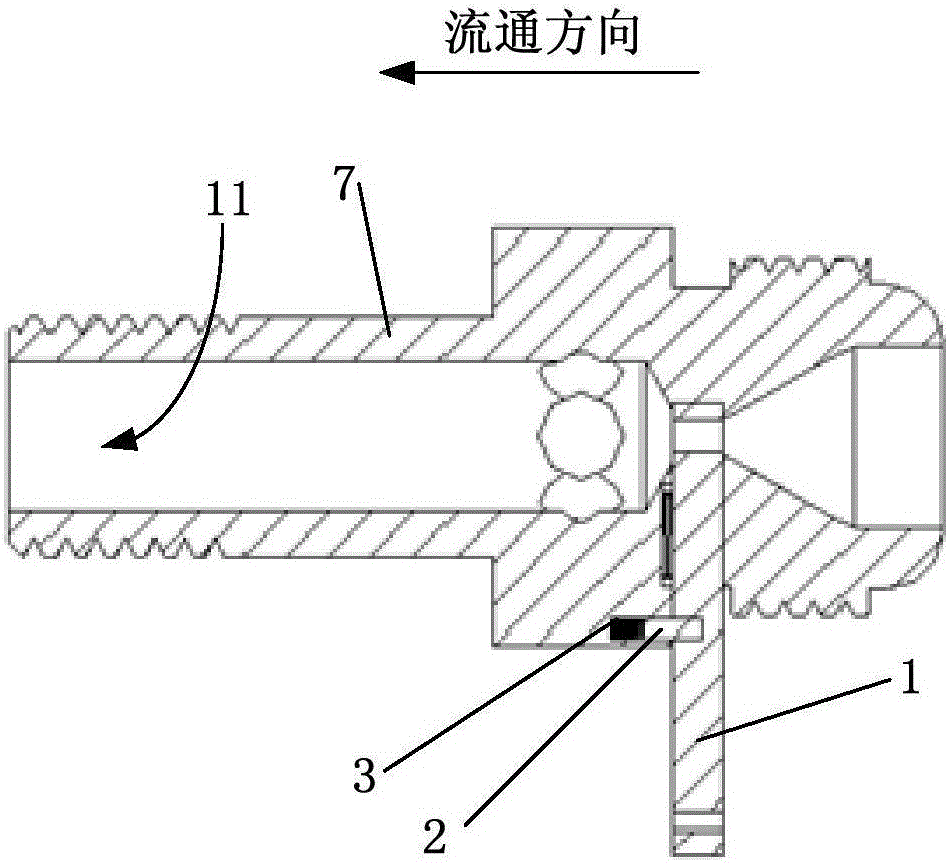

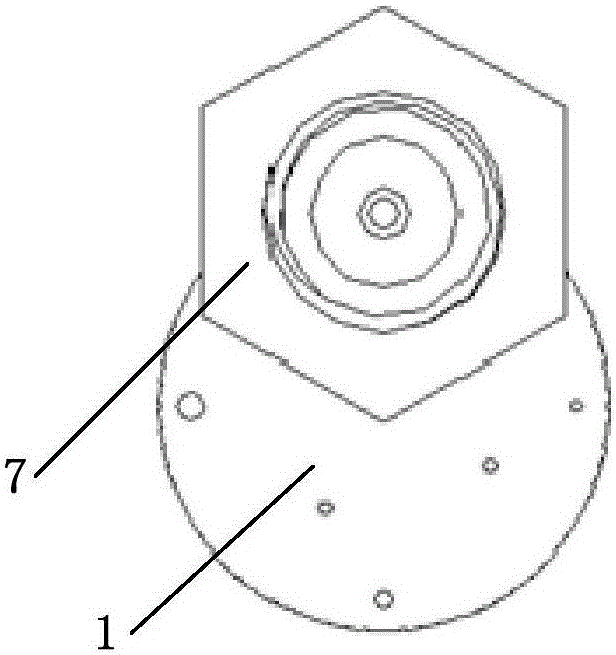

[0068] ginseng Figure 13 , The technical solution of this embodiment has the following differences from the technical solutions of the above-mentioned embodiments. In this embodiment, the adjustment member adopts the following structure: the adjustment member 1 is a plate-shaped structure, and the adjustment member 1 is provided with a chute 21 . A groove 71 is provided on the side of the nozzle body 7 . The groove 71 is connected to the gas flow channel 11 . Wherein, the width dimension of the chute 21 is variable, and at least part of the width dimension of the chute 21 is smaller than the inner diameter dimension of the gas flow channel 11 . ID dimensions refer to diameters.

[0069] The flow rate corresponding to at least part of the width dimension of the chute 21 is smaller than the flow rate of the gas flow channel 11, so that after the chute 21 rotates, after the width of the chute 21 communicating with the gas flow channel 11 changes, it flows through the chute 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com